Characteristics of PPR pipes

1. Environmental protection and safety

PPR pipes meet the sanitation standards for drinking water and do not contain harmful substances. They are a green and environmentally friendly material. It does not contain any toxic substances, ensuring the health of the transported water, and is particularly suitable for domestic water pipe systems.

2. High temperature and high pressure resistance

PPR pipes have excellent heat resistance and can withstand hot water and high pressure environments up to 95°C. They are widely used in heating systems and hot water supply systems. Under normal conditions, the service life of PPR pipes can reach 50 years, with a long durability period.

3. Corrosion resistance

PPR pipes have extremely strong chemical corrosion resistance and good resistance to chemicals such as acids, alkalis, and salts. They are especially suitable for transporting hot and cold water, corrosive liquids, and other occasions.

4. Easy installation

PPR pipes use hot-melt connection technology, the connection process is simple and firm, ensuring the sealing and durability of the pipeline system. In addition, PPR pipes are light and easy to transport and install.

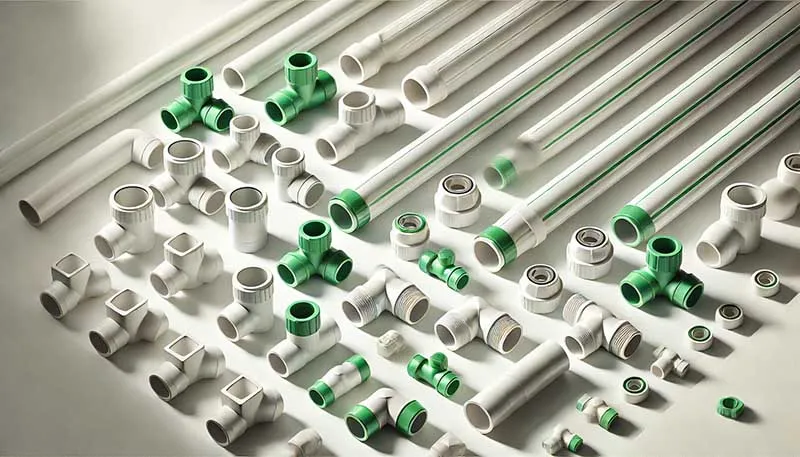

Classification of PPR pipes

According to different standards, PPR pipes can be divided into the following categories

1. Classification by use

① Cold water pipes

Suitable for conveying cold water not exceeding 40°C, mainly used in household water supply systems.

Usually the pipe wall is thinner and marked as PN1.6 or PN2.0 (pressure resistance grade).

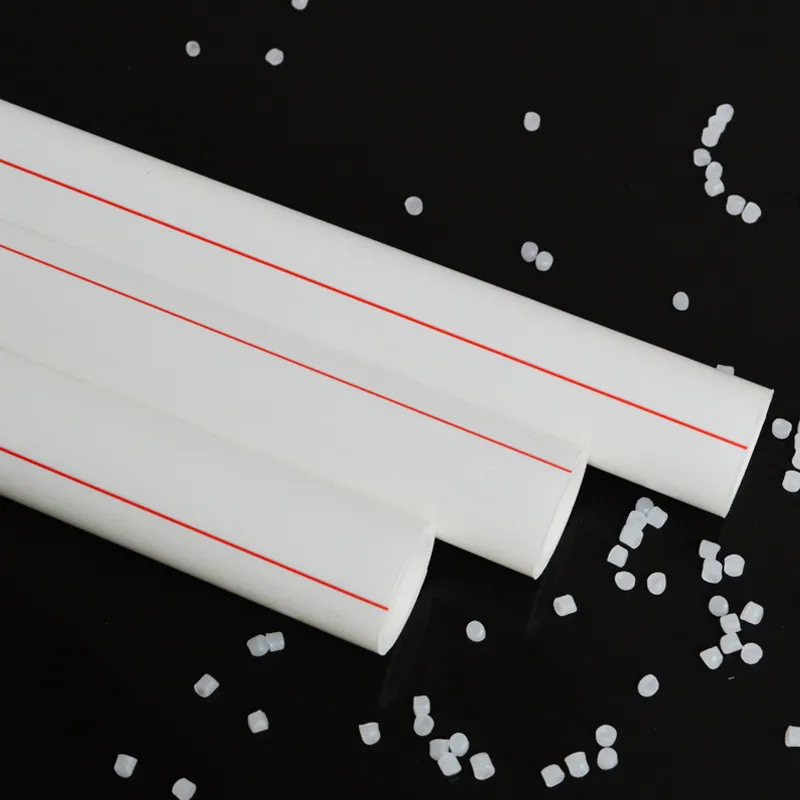

② PPR hot water pipe

Can withstand hot water up to 95°C, suitable for household hot water supply and heating systems.

The ppr hot water pipe wall is thicker and has stronger pressure resistance, marked as PN2.5 or higher.

Key Features of PPR Hot Water Pipes

High-Temperature Resistance

PPR hot water pipes can withstand temperatures up to 95°C continuously, making them ideal for hot water distribution and heating systems.

Excellent Pressure Resistance

Depending on their pressure rating (e.g., PN2.5 or PN3.2), they can handle high water pressure without deformation.

Thermal Insulation

The material has a low thermal conductivity, reducing heat loss and improving energy efficiency.

Corrosion Resistance

Resistant to scaling, rust, and chemical corrosion, ensuring a long service life even in challenging water conditions.

Non-Toxic and Hygienic

PPR pipes are safe for transporting drinking water, meeting health and safety standards.

2. Classification by appearance color

① White PPR pipes

The most common, suitable for various occasions.

The appearance is simple and matches a variety of decoration styles.

② Green PPR pipes

A symbol of more environmental protection, suitable for drinking water systems.

③ Gray or blue PPR pipes

Commonly used in industry or special purposes.

3. Classification by pressure level

According to the nominal pressure (PN value), it is divided into

① PN1.6 (1.6 MPa)

Suitable for low-pressure cold water systems.

② PN2.0 (2.0 MPa)

Suitable for cold water or lower temperature hot water systems.

③ PN2.5 (2.5 MPa)

Suitable for hot water supply and heating systems.

4. Classification by connection method

① Hot-melt PPR pipe

Connected by hot-melt machine after heating, most commonly used, good interface sealing.

② Mechanical connection PPR pipe

Connected by threaded joints and other methods, easy to install, but not as strong as hot melt.

5. Classification by reinforcement layer

① Ordinary PPR pipe

Single-layer PPR material.

② Aluminum-plastic composite PPR pipe

An aluminum layer is sandwiched in the middle to enhance strength and reduce thermal expansion.

③ Glass fiber reinforced PPR pipe

Adding glass fiber layer, high temperature resistance, low expansion, suitable for hot water and heating systems.

6. Classification by usage scenario

①Household water supply pipe

Suitable for hot and cold water supply in kitchens and bathrooms.

②Heating pipe

Used for floor heating or radiator connection.

③Industrial delivery pipe

Transport chemical liquids or industrial cooling water.

④Agricultural irrigation pipe

Used for farmland or greenhouse irrigation.

PPR pipes are classified in many ways according to purpose, pressure, color, connection method, etc. When selecting PPR pipes, the appropriate type should be determined according to specific needs (such as working pressure, temperature, and purpose) to ensure safe, efficient and durable performance. If further help is needed, specific scenarios can be provided to recommend the best selection scheme.

Application areas of PPR pipes

PPR pipes are widely used in the following major areas

1. Water supply system

The most common application of PPR water pipe is for water supply pipe systems, including household hot and cold water pipes, urban water supply pipes, etc. Due to its corrosion resistance, non-toxicity and hot-melt connection characteristics, PPR pipes have become one of the most commonly used pipes in modern buildings.

2. Heating system

PPR water pipe are also commonly used in floor heating and radiator systems. They can withstand high temperatures, have good pressure resistance, and are suitable for all types of heating systems.

3. Industrial applications

PPR water pipe can be used not only for cold and hot water transportation, but also for low-corrosive industrial liquids, and are widely used in chemical, food processing, pharmaceutical and other industries.

4. Agricultural irrigation

In the field of agricultural irrigation, PPR water pipe are widely used. It has high corrosion resistance and aging resistance, can be used for a long time in various climatic conditions, and is suitable for greenhouse irrigation and field irrigation systems.

Installation tips for PPR pipes

The installation process of PPR pipes is relatively simple, but it still needs to be operated in accordance with standard specifications

1. Pipe cutting and cleaning

Use a special pipe cutting tool, pay attention to the flatness of the cut when cutting, and avoid burrs affecting the connection quality. After cutting, use a deburring tool to clean the inner and outer ports of the pipe.

2. Hot melt connection

Use a hot melt machine to heat the connecting end of the pipe and the fitting to the specified temperature. When connecting, quickly insert the fitting to ensure that the ends of the pipe and the fitting are fully fused. After the connection is completed, hold it for a few seconds and wait for cooling and solidification.

3. Pressure test

After installation, a system pressure test should be performed to ensure that there is no leakage in the pipe interface. Generally speaking, the system pressure test should last at least 30 minutes.

Maintenance methods of PPR pipes

1. Regular inspection

Regularly check the connection parts of the PPR pipe system to ensure that there is no leakage or aging. Especially for a period of time after the system is installed, pay close attention to the sealing of the interface.

2. Antifreeze protection

In cold areas, PPR pipes should be insulated to avoid damage to the pipes due to freezing of water flow in low temperature environments.

3. Avoid exposure to strong sunlight

Although PPR pipes have a certain UV resistance, long-term exposure to sunlight may cause pipe aging. Therefore, pipes exposed outdoors should be shielded or coated with UV protection coatings.

4. Cleaning and dredging

Since PPR pipes are not easily corroded, sediments may accumulate during long-term use. Clean the pipes regularly to avoid debris blocking the pipes.

PPR pipes have the advantages of high temperature resistance, corrosion resistance, safety and environmental protection, and easy installation, making them ideal pipe materials in modern construction, industry, agriculture and other fields. Whether in water supply systems, heating systems, industrial transportation, or agricultural irrigation, PPR pipes have shown their unique advantages. In terms of installation and maintenance, as long as they are operated in accordance with standard specifications, PPR pipes can provide users with long-term and stable services.

If you have more specific applications or installation questions about PPR pipes, please feel free to consult us. We will provide professional technical support and suggestions.

659.webp)

210.webp)

328.webp)

294.webp)

476.webp)