Compression Fittings for PE Pipe

Compression fittings for PE (polyethylene) pipes are widely used in irrigation, water supply, and various low-pressure fluid systems due to ...

Double Wall Corrugated Pipe Fittings HDPE

HDPE Pipe Fittings and Double Wall Corrugated Pipe Fittings are essential components in modern pipeline systems, offering durability and ver...

Aluminum Alloy Plastic Lined Composite Pipe

Aluminum alloy lined plastic composite pipe is a new type of practical pipe developed on the basis of traditional plastic pipes. It combines...

ABS Water Outlet

ABS water outlets have become an ideal choice in water supply systems because of their corrosion resistance, lightness, high strength and en...

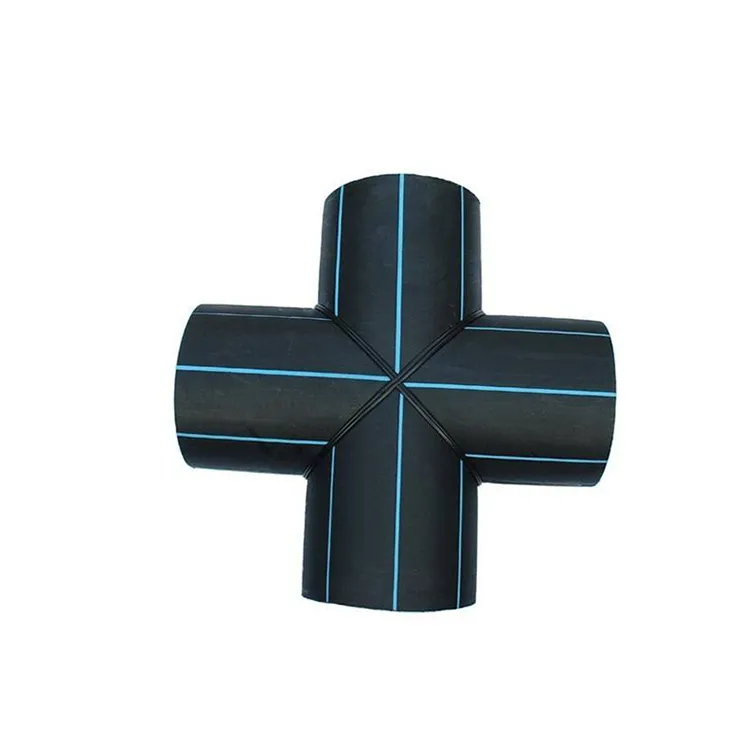

HDPE Cross Pipe Fittings

To find the Versatility of HDPE Cross Pipe Fittings. Engineered for precise connections, these fittings facilitate efficient fluid flow and ...

HDPE butt fusion joint fittings

High-Density Polyethylene (HDPE) fittings are components used in piping systems to connect, control, or adapt the flow of HDPE pipes in vari...

PERT Ⅱ Electrofusion Pipe Fitting

Pert-2 fittings represent a cutting-edge solution in the field of plumbing and heating systems. These fittings are designed to offer excepti...

PE Pipe Fittings Electrofusion EF HDPE fittings

Discover premium HDPE electrofusion fittings at Haili Pipe Company. With over a decade of expertise, we're your reliable choice for high-qu...

PVC electrical conduit 90 degree elbow Size and Dimensions

A PVC electrical conduit 90 degree elbow is a type of conduit fitting used to connect two pieces of electrical conduit at a 90 degree angle....

Here are 5 Kinds of Electrofusion Pipe Fittings That Are Usually Used

Electrofusion fittings, also commonly known as electrofusion joints, are pipe fittings that allow for the passage of multiple liquids from d...

110 x 45° PE100 Elbow Connectors

Elbow connectors are used to connect one pipe or tube to another. They come in many different sizes, each for a specific application. One of...

Fitting a 90*90*90mm Equal Tee SDR11 PE100

Equal tee fittings are popular because they can be used to connect two different pipes of different sizes while still meeting the requiremen...

90° DN110 to 90mm SDR11 Reducing Elbow HDPE Pipe Fittings

Reducing elbows are the most common type of pipe fittings used in any kind of plumbing system. They are also known as reduction joints and t...

HDPE Reducing Tee Pipe Fittings 25-110mm

The water industry is constantly looking for ways to reduce costs, increase efficiency and reduce waste. The use of plastic pipe, fittings a...

HDPE Equal 135° Elbows Pipe Fittings

HDPE equal 135° elbows pipe fittings are essential components of any piping system, providing flexible connections between two pipes, valves,...

HDPE Threaded Adapter Fittings

The use of plastic thread adapters has increased by 150% in the past five years. That’s because these fittings are indispensable for connect...

63mm 2.5Mpa HDPE Butt Fusion Ball Valves

Installing butt fusion ball valves is probably one of the simplest plumbing tasks you can perform. It’s also one that’s very popular, especi...

Different Varieties of 63, 110, 160, and 200mm HDPE Ball Valves

HDPE, or high-density polyethylene, is one of the most common materials used in pipe fittings and valves. HDPE ball valves come in a variety...

☛Pipe Fittings Guides

Table of Contents

Chapter 1: About pipe fittings

1.1 HDPE pipe fittings and pvc pipe fittings

1.4 What type of pipe material are the fittings compatible with?

1.5 What is the pressure rating of the fittings?

1.6 What is the temperature rating of the pipe fittings?

1.7 What type of jointing method is used for the pipe fittings?

1.9 What is the manufacturing process used for the fittings?

Chapter 1: About pipe fittings

Various types of HDPE pipe fittings are available in plumbing systems for different purposes and functions. A HDPE pipe fitting is used in plumbing system to join multiple pipes of same size or different sizes, to regulate the flow or to measure the flow.

HDPE pipe has strong corrosion resistance, does not need anti-corrosion treatment, saves cost, and the comprehensive economic benefit is 5-6 times that of steel pipe without excavation, and it is not easy to scale. It is suitable for underground transportation of media containing calcium, sulfur and magnesium ions.

HDPE pipe fitting is a good pipe fitting, which should not only have good economy, but also have a series of advantages such as stable and reliable interface, impact resistance, cracking resistance, aging resistance and corrosion resistance.

HAILI’s pipe fittings production line include Piping Elbows, Piping Reducers, Tee Connections, Olet Connections, Caps, Crosses, etc. HAILI’s fitting have spread throughout East Asia, South Asia, South America, Middle East and Africa, and are the premium choice for local distributors and customers.

1.1 HDPE pipe fittings and pvc pipe fittings

HDPE (high-density polyethylene) and PVC (polyvinyl chloride) pipes are two popular types of plastic pipes used in a variety of applications. Here are some of the key differences between HDPE pipe fittings and PVC pipe fittings:

1. Material: HDPE pipe fittings are made from high-density polyethylene, while PVC pipe fittings are made from polyvinyl chloride.

2. Chemical resistance: HDPE is highly resistant to chemicals and is commonly used in chemical processing and water treatment plants. PVC is also resistant to chemicals but may not be suitable for certain highly corrosive chemicals.

3. Temperature resistance: HDPE is highly resistant to temperature changes and can handle extreme temperatures, making it ideal for outdoor applications. PVC is less tolerant of extreme temperatures and may become brittle in cold weather.

4. Jointing methods: HDPE fittings can be joined using a variety of methods, including butt fusion, electrofusion, and compression. PVC fittings are typically joined using solvent welding, which involves melting the pipe and fitting together using a special solvent.

5. Cost: HDPE fittings are generally more expensive than PVC fittings due to the higher cost of materials and manufacturing.

In terms of specific fittings, both HDPE and PVC pipes can use a variety of fittings including elbows, tees, couplings, reducers, and adapters. However, the specific fittings used will depend on the application and the specific requirements of the project.

1.2 HDPE pipe fittings types

There are several types of HDPE (high-density polyethylene) pipe fittings, including:

1. Butt Fusion Fittings: These fittings are used to join two HDPE pipes together by heating the ends of the pipes and then fusing them together using a specialized butt fusion machine.

2. Electrofusion Fittings: Electrofusion fittings use an electric current to heat up and melt the HDPE pipe and fitting materials, creating a strong, permanent bond between the two parts.

3. Compression Fittings: Compression fittings are designed to connect HDPE pipes using a compression nut and ring, which are tightened onto the pipe to create a tight seal.

4. Transition Fittings: Transition fittings are used to connect HDPE pipes to other types of pipes, such as PVC or steel pipes.

5. Flange Adapters: Flange adapters allow HDPE pipes to be connected to flange-style fittings or other equipment.

6. Fabricated Fittings: Fabricated fittings are custom-made HDPE fittings designed to meet specific project requirements, such as large-diameter fittings or fittings with special angles or shapes.

Each type of HDPE pipe fitting has its own unique advantages and applications, and the selection of the right fitting for a particular project will depend on a variety of factors, including the type of pipe being used, the application, and the environmental conditions.

1.3 PVC pipe fittings types

There are many types of PVC (polyvinyl chloride) pipe fittings, including:

1. Couplings: Couplings are used to connect two lengths of PVC pipe together in a straight line.

2. Elbows: Elbows are fittings that allow for changes in direction of the PVC pipe. They come in a variety of angles, such as 90 degrees or 45 degrees.

3. Tees: Tees are fittings that allow a PVC pipe to branch off in a perpendicular direction.

4. Crosses: Crosses are similar to tees, but they have a fourth connection point that allows for a second perpendicular PVC pipe to be added.

5. Caps: Caps are used to seal off the end of a PVC pipe.

6. Adapters: Adapters allow for PVC pipes to be connected to other types of pipes, such as copper or galvanized steel.

7. Reducers: Reducers allow for a PVC pipe to be connected to a smaller diameter PVC pipe.

8. Wyes: Wyes are similar to tees, but they have a diagonal branch that allows for changes in the direction of the PVC pipe.

9. Unions: Unions are fittings that allow for easy disassembly of a PVC pipe system.

These are just a few examples of the many types of PVC pipe fittings available. The selection of the right fitting for a particular project will depend on a variety of factors, including the size and type of PVC pipe being used, the application, and the environmental conditions.

1.4 What type of pipe material are the fittings compatible with?

The type of pipe material that pipe fittings are compatible with depends on the specific fitting and its design. For example, some fittings may be designed specifically for use with PVC (polyvinyl chloride) pipes, while others may be compatible with HDPE (high-density polyethylene) pipes or other types of plastic or metal pipes. It is important to select fittings that are specifically designed to work with the type of pipe material being used in order to ensure a proper fit and prevent leaks or other issues. When selecting fittings, it is important to check the manufacturer's specifications and recommendations to ensure that the fittings are compatible with the type of pipe material being used.

1.5 What is the pressure rating of the pipe fittings?

The pressure rating of pipe fittings depends on the type of material they are made from, the size of the fitting, and the temperature and pressure conditions under which they will be used. For example, PVC pipe fittings typically have a pressure rating of between 150 to 450 PSI (pounds per square inch), while HDPE pipe fittings can have a pressure rating of up to 335 PSI.

It is important to select pipe fittings that have a pressure rating that is appropriate for the application they will be used in. Using fittings with a lower pressure rating than necessary can result in leaks or system failure, while using fittings with a higher pressure rating than necessary can lead to unnecessary costs.

It is also important to ensure that the pressure rating of the fittings matches the pressure rating of the pipes they are being connected to. If the pressure rating of the fittings is lower than that of the pipes, the fittings may become a weak point in the system, leading to failure or leaks.

1.6 What is the temperature rating of the pipe fittings?

The temperature rating of pipe fittings is another important factor to consider when selecting the appropriate fittings for a given application. The temperature rating of the fittings refers to the maximum temperature that the fittings can safely handle without experiencing degradation or failure.

The temperature rating of pipe fittings can vary depending on the type of material they are made from. For example, PVC pipe fittings typically have a temperature rating of between 140°F to 160°F, while HDPE pipe fittings can typically handle temperatures up to 140°F.

It is important to select fittings with a temperature rating that is appropriate for the temperature range that the system will be operating under. Using fittings with a lower temperature rating than necessary can result in degradation or failure of the fittings, while using fittings with a higher temperature rating than necessary can lead to unnecessary costs.

Additionally, it is important to ensure that the temperature rating of the fittings matches the temperature rating of the pipes they are being connected to. If the temperature rating of the fittings is lower than that of the pipes, the fittings may become a weak point in the system, leading to failure or leaks.

1.7 What type of jointing method is used for the pipe fittings?

The type of jointing method used for pipe fittings can vary depending on the material of the fittings and the pipes they are being connected to. Some common jointing methods for pipe fittings include:

1. Solvent welding: This is a common jointing method used for PVC pipe fittings. Solvent welding involves using a solvent cement to join the fitting and the pipe together, which creates a strong, leak-proof bond.

2. Compression fittings: This type of jointing method is often used for PE and PEX pipe fittings. Compression fittings work by compressing a sealing ring between the fitting and the pipe, creating a tight, secure connection.

3. Electrofusion welding: This is a jointing method used for HDPE pipe fittings. Electrofusion welding involves using an electrofusion welding machine to heat the fitting and the pipe, fusing them together to create a strong, durable joint.

4. Mechanical couplings: This type of jointing method is often used for large diameter pipes and fittings. Mechanical couplings use a series of bolts and gaskets to join the fitting and the pipe together.

It is important to select the appropriate jointing method for the pipe fittings based on the material of the fittings and the pipes they are being connected to, as well as the specific requirements of the application. Using the wrong jointing method can lead to leaks, system failure, or reduced durability.

1.8 Are the fittings designed for specific applications, such as high-pressure or corrosive environments?

Yes, pipe fittings are often designed for specific applications, such as high-pressure or corrosive environments. For example, fittings made of materials like stainless steel, brass, or copper may be used in applications where corrosion resistance is important. High-pressure applications may require fittings made of materials with higher strength or thicker walls to withstand the pressure.

Pipe fittings may also be designed with specific features to accommodate particular applications. For instance, fittings for underground piping systems may include a protective coating to prevent corrosion from soil, or they may have a bell-shaped end for easy installation and to prevent soil from entering the pipe.

When selecting pipe fittings for an application, it is important to consider the specific requirements and conditions of the application, such as the fluid being conveyed, the pressure and temperature of the system, and any corrosive or abrasive factors. Choosing fittings that are designed for the specific application can help ensure a reliable and long-lasting system.

1.9 What is the manufacturing process used for the fittings?

The manufacturing process for pipe fittings can vary depending on the material used, the type of fitting, and the manufacturing methods employed by the manufacturer.

For plastic pipe fittings like HDPE and PVC, the most common manufacturing process is injection molding. In this process, plastic pellets are heated and melted in a machine, and then injected into a mold cavity under high pressure. The plastic cools and solidifies in the mold, forming the shape of the fitting.

For metal pipe fittings, the manufacturing process may involve casting, forging, or machining. Casting involves pouring molten metal into a mold and allowing it to solidify into the shape of the fitting. Forging involves shaping the metal by hammering or pressing it into a die, while machining involves removing material from a block of metal using cutting tools to form the shape of the fitting.

Regardless of the manufacturing process used, it is important for manufacturers to adhere to industry standards and best practices to ensure the quality and reliability of the fittings. This includes rigorous testing and quality control measures to ensure the fittings meet the required specifications and performance standards.

Products

News

SDR 11 vs SDR 17 Pressure Rating HDPE pipe fittings names and images 40mm black waste pipe Top 5 HDPE Pipe Manufacturers in Vietnam Fusion Weld Fittings EF CouplerContact

No.1 of Wenhua Road, Pingyin county, Jinan city, Shandong province, China.

328.webp)

294.webp)

287.webp)

274.webp)