Krah tube (HDPE winding B-type tube)

1. What is a Krah tube?

Krah tube (HDPE winding reinforced tube) is a high-density polyethylene structure wall thermal winding tube, HDPE winding structure wall tube, which is a new type of special-shaped structure wall tube, which is made by high-density polyethylene thermal winding molding process.

2. Application fields of Krah tube:

1) Sewage system:

Various wall structures and pipes of thermal structure wall wound pipes, inspection wells, and pipe fittings can be used in advanced shallow drainage systems due to their reliable connection performance.

2) Drainage system:

For discharging liquid and gaseous substances into rivers or seas. The thermal structure wall wound pipe has the advantages of light weight, safety, reliable connection, corrosion resistance and high ring stiffness, so the use of the thermal structure wound pipe has great advantages.

2. Hollow pipe (HDPE hollow wall winding pipe)

1. What is a hollow tube?

The full name of the hollow pipe is HDPE hollow wall winding pipe. The hollow pipe is a structural wall pipe made of high-density polyethylene (HDPE) as raw material and using a thermal winding process. The connection method adopts the elastic connection method of white steel clamp.

2. Application fields of hollow tubes:

Hollow pipe (HDPE hollow wall winding pipe) is suitable for municipal drainage, building outdoor drainage, buried farmland transportation and drainage, industrial sewage, road drainage, sewage treatment plant, sports field square engineering drainage and electrical telecommunication with water temperature below 45 ℃ Engineering etc. Since the hollow tube is a chemical building material, it is of great significance to save energy, reduce pollution and protect the environment.

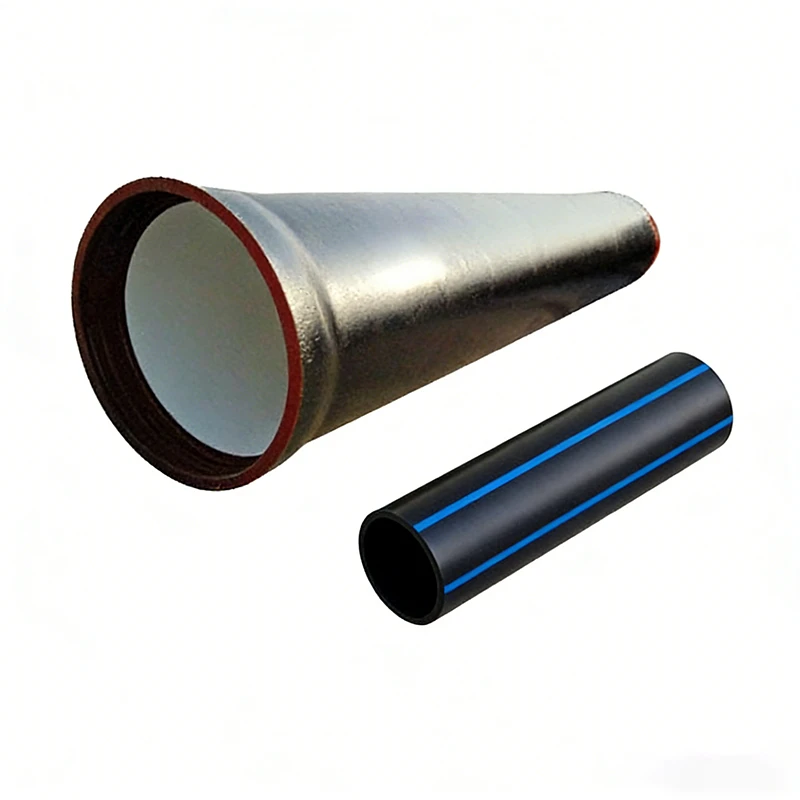

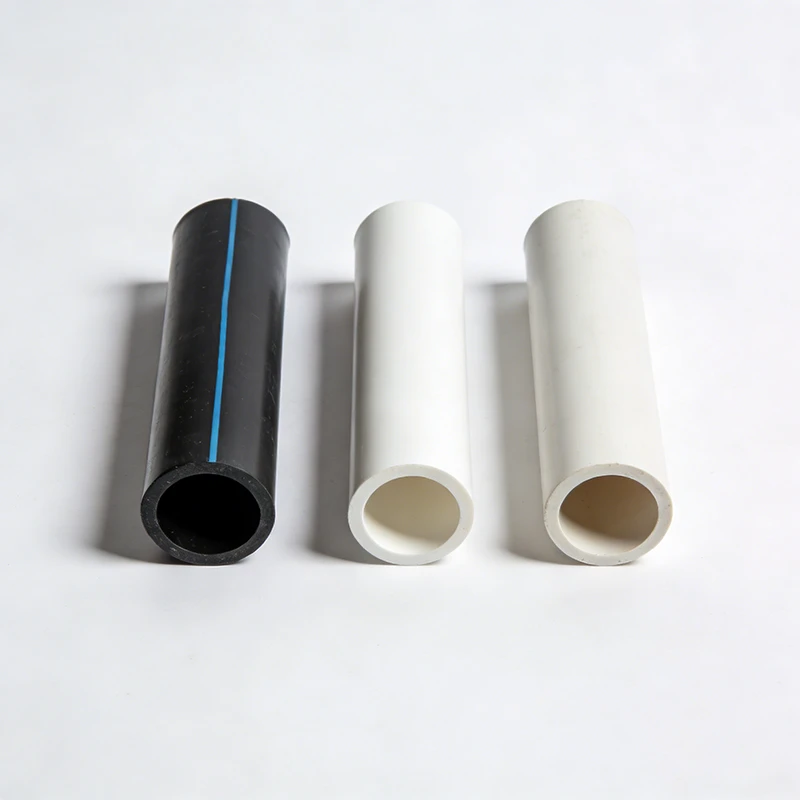

3. The difference between Krah tube and hollow wall tube

1. The Krah tube is made of German equipment and technology, using high-density polyethylene (HDPE) material as raw material, wound and formed in a hot-melting state, cooled by natural wind, and demolded in a cold state, in line with the national standard GB/T19472.2- 2004 Specified B-type structural wall pipe. The hollow tube adopts domestic equipment and technology, uses high-density polyethylene material (HDPE) as raw material, is wound and formed in a hot-melting state, and is water-cooled. In the process, the square tube is first extruded, cooled by water and then shaped, then wound into a circular tube, and then cooled by water.

Comparing the two, the advantages of the Krah tube:

A) The hot-melt state is wound, the inner and outer walls of the structure wall are synchronously wound, and the overall pipe is uniform and there is no weld.

B) Using air cooling, the heat stored in the tube is completely dissipated in the forming process, no internal stress is formed, and no delamination and cracking.

C) Cold demoulding, when the pipe is cooled to room temperature, it is demolded by mold shrinkage, and the pipe will not be deformed.

Comparing the two, the defects of the hollow tube:

A) There are obvious welds, and the length is long, and the quality is difficult to control.

B) The water cools quickly, the heat is dissipated unevenly, and there is stress on the structural wall. Spring-like splits often occur with poor control.

C) The outer wall is smooth, which cannot effectively suppress the longitudinal displacement caused by thermal expansion and contraction of PE material, which often causes stress concentration at both ends of the pipeline, destroys the connection between the joint or the pipeline and the inspection well, and causes water leakage.

2. The inertia moment of the Krah pipe (HDPE wound B-type pipe) is continuously adjustable and the value can reach 19.8, so the pipe ring stiffness is high, and the pipe above DN1500 can still produce pipe above 16KN/m2. As for the hollow pipe (HDPE hollow wall winding pipe), the structural wall height is limited, the adjustable moment of inertia can only reach 5, and the ring stiffness of the pipe that can be produced is low, basically 8KN/㎡, when the pipe is larger than DN1000 or more When the ring stiffness is SN4 (≥4KN/㎡).

3. Krah tube (HDPE wound B-type tube) has extremely high requirements on the performance of product raw materials during production, so except for 2% of the color masterbatch, all other materials are HDPE materials, so the price is relatively low. The hollow tube (HDPE hollow wall winding tube) produces more consumables per unit ring stiffness, so the cost is higher. However, due to the small investment in production equipment and the low threshold, there are many manufacturers. Under the disordered market competition, in order to gain an advantage in cost, a large number of inorganic substances (calcium carbonate) and recycled materials are used, resulting in the price difference in the market. Larger, and ridiculously low.

4. The Krah pipe (HDPE wound B-type pipe) adopts socket-type electrofusion connection (rigid interface), and the interface part adopts socket-socket and electrofusion methods to be used at the same time, which ensures the force capacity of the pipe interface and also ensures The tightness of the interface. The Krah pipe (HDPE wound B-type pipe) has a strong ability to withstand unevenness, and the construction methods can be diversified. In areas that require rapid backfill, the Krah pipe (HDPE wound B-type pipe) can be pre-welded on the ground for multiple pieces, and then placed into the groove. The hollow pipe (HDPE hollow wall winding pipe) is connected by (electric) hot-melt tape. Due to the deformation of the pipe port, the (electric) hot-melt tape cannot be completely bonded to the pipe. It must be welded in the groove during construction. Larger earthwork excavation, construction speed is slow. (Electric) hot-melt belt connection, the force structure is poor, and the welded seam of the pipe is long, so it cannot adapt to the laying in the area of soft foundation or uneven settlement.

5. Compared with the Krah tube (HDPE winding B-type tube, B-type tube) and hollow tube (HDPE hollow wall winding tube, A-type tube) of the same material, the B-type tube is technically superior to the A-type tube, In application, the B-type pipe is even better than the A-type pipe. Under the same indicators, the two types of pipe materials are similar, and the normal price should be almost the same. Therefore, the cost-effectiveness of the B-type pipe is obviously better than that of the A-type pipe.

6. Krah pipe (HDPE wound B-type pipe) is widely used in key projects, especially in areas with uneven settlement in coastal areas. The hollow pipe (HDPE hollow wall winding pipe) has been restricted in some key projects due to its unreasonable process and structure, the material is not pure enough, and the engineering safety is too low. It is generally not used in coastal areas.

160.webp)

856.webp)

659.webp)

210.webp)

328.webp)

294.webp)

476.webp)