Specification

Pipe Detail

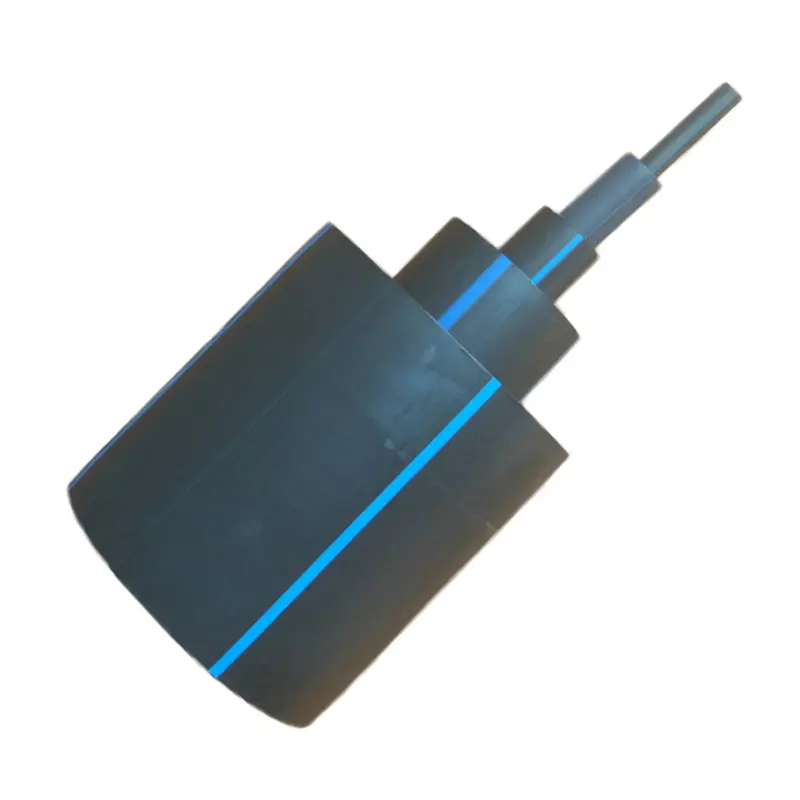

| Product Name | HDPE Pipe (Poly Pipe) In Black/Blue Color For Water Supply |

| Specification available | DN16-1600mm (outer diameter) |

| SDR/pressure ratings | For HDPE Pipe be made of PE100 grade material: |

| SDR9-PN20, SDR11-PN16, SDR13.6-PN12.5, SDR17-PN10, SDR21-PN8, SDR26-PN6, SDR33-PN5, SDR41-PN4 | |

| For HDPE pipe be made of PE80 grade material: | |

| SDR9-PN16, SDR11-PN12.5, SDR13.6-PN10, SDR17-PN8, SDR21-PN6, SDR26-PN5, SDR33-PN5 | |

| Material to be used | Virgin PE80 or PE100 raw material from worldwide famous suppliers, like Borealis, Sabic, Sinopec..etc |

| Colors available | Black color with blue strips or blue color, or as per request |

| Markings on the pipe | As per customer's request. |

| Samples available | Yes, small quantity of samples available. |

| MOQ | Negotiable |

| Production lead time | 3-5 days for a 20ft container, 5-7 days for a 40ft container. |

| Warranty time | 15 years for normal use |

| Payment term | T/T or LC at sight |

| FOB loading port | Qingdao or Tianjin China |

| Place of origin | Jinan, China |

Poly Pipe in Black/Blue Color for Water Supply Specification

If you need a quotation, please contact us or leave us a message!

What material is HDPE?

HDPE is a highly crystalline, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. PE has excellent resistance to most household and industrial chemicals. Certain types of chemicals are chemically aggressive, such as corrosive oxidants (concentrated nitric acid), aromatic hydrocarbons (xylene), and halogenated hydrocarbons (carbon tetrachloride).

The polymer is non-hygroscopic and has good water vapour resistance for packaging applications. HDPE has good electrical properties, especially high insulation dielectric strength, making it very suitable for wires and cables. Medium to high molecular weight grades have excellent impact resistance at ambient temperatures and even as low as -40F.

Our Factory

FAQ:

Q: What is your MOQ?

A: As customer's request.

Q: Why choose us?

A: We are a professional leader in HDPE pipe factories, we offer pipeline system one-stop services with competitive prices and fast delivery time.

Q: How to buy the product?

A: Contact us by email or by Trade Manager, and inform us which product and quantity you need, we will contact you immediately. The more specific the information that you provide more faster and easier you will get the quotation.

Q: Can I make my own design and logo on the product?

A: Yes, we do OEM. Welcome partner from globally, we can make your product in China.

Q: How can I get some samples?

A: We are honored to offer you free samples, just need to pay the freight cost.

Q: What's the payment term?

A: TT/LC

We welcome customers from all over the world to visit the factory. If you need to visit the factory, please contact us on the website first!

What are the advantages of HDPE water pipes?

HDPE is a good pipeline, not only should have good economy, but also should have a series of advantages such as stable and reliable interface, material impact resistance, crack resistance, aging resistance, corrosion resistance, etc.

Compared with traditional pipes, HDPE pipeline system has The following series of advantages:

1. Reliable connection: The polyethylene piping systems are connected by electrothermal fusion, and the strength of the joint is higher than that of the pipe body.

2. Good impact resistance at low temperature: The low temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60 °C. During construction in winter, due to the good impact resistance of the material, the pipe will not be brittle.

3. Good resistance to stress cracking: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its resistance to environmental stress cracking is also very outstanding.

4. Good chemical corrosion resistance: HDPE pipes are resistant to corrosion by a variety of chemical media, and the chemicals present in the soil will not cause any degradation to the pipes. Polyethylene is an electrical insulator, so it does not rot, rust or electrochemically corrode; it also does not promote algal, bacterial or fungal growth.

What are the characteristics of HDPE water pipes?

A good pipeline should not only have good economy, but also have a series of advantages such as stable and reliable interface, material impact resistance, crack resistance, aging resistance and corrosion resistance. HDPE water supply pipe is a product made of synthetic resin and additives by melt molding. Additives include plasticizers, stabilizers, fillers, lubricants, colorants, UV absorbers, modifiers, and the like. HDPE pipes are mainly used for: municipal engineering water supply systems, indoor water supply systems in buildings, outdoor buried water supply systems and residential quarters, buried water supply systems in factories, repair of old pipelines, water treatment engineering pipeline systems, gardening, irrigation and other fields of industry water pipes, etc.

(1) Reliable connection: The polyethylene pipe system is connected by electrothermal fusion, and the strength of the joint is higher than that of the pipe body.

(2) Good low temperature impact resistance: The low temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60 °C. During construction in winter, due to the good impact resistance of the material, the pipe will not be brittle.

(3) Good resistance to stress cracking: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its resistance to environmental stress cracking is also very outstanding.

⑷Good chemical corrosion resistance: HDPE pipes are resistant to corrosion by a variety of chemical media, and chemical substances in the soil will not cause any degradation to the pipes. Polyethylene is an electrical insulator, so it does not rot, rust or electrochemically corrode; it also does not promote algae, bacterial or fungal growth.

⑸Aging resistance, long service life: polyethylene pipes containing 2-2.5% of carbon black evenly distributed can be stored or used outdoors for 50 years without being damaged by ultraviolet radiation.

⑹ Good wear resistance: The comparison test of wear resistance of HDPE pipe and steel pipe shows that the wear resistance of HDPE pipe is 4 times that of steel pipe. In the field of mud transportation, compared with steel pipes, HDPE pipes have better wear resistance, which means that HDPE pipes have longer service life and better economy.

⑺Good flexibility: The flexibility of HDPE pipes makes it easy to bend, and in engineering, obstacles can be bypassed by changing the direction of the pipes. In many occasions, the flexibility of the pipes can reduce the amount of pipe fittings and installation costs.

Wholesale 2 in. x 500 ft HDPE water pipe roll

In the process of reproducing HDPE water pipes, we roll the pipes into rolls for convenient storage and transportation. 2 in. x 500 ft HDPE water pipe is one roll. We are the source manufacturer of 2 in. x 500 ft HDPE water pipe roll from China. Provide high quality 2 in. x 500 ft HDPE water pipe for you. If you are ready to purchase HDPE water pipe, we wholesale water pipe roll to you with ex-factory price.

Wholesale 2 in. x1000 ft HDPE water pipe roll

The second HDPE water pipe roll specification, 2 in. x1000 ft HDPE water pipe is a roll. Our raw material self-sufficiency rate reaches more than 60%, so we have great price advantage in manufacturing HDPE water pipe roll. Therefore, we hope that our partners have certain sales channels and purchasing capabilities. We use the highest quality HDPE water pipe and the most advantageous price to help you gain more competitive advantage in the local market.

If you don't have your own brand, we can wholesale HDPE water pipes to you. If you have your own brand, we can provide OEM plumbing service.

Pressure capacity of HDPE water supply pipes

There are different series models of HDPE water pipes. For water supply pipes, the pipe material printing labels are: SDR33, SDR26, SDR21, SDR13.6, SDR11, and the corresponding pressures are: 0.4MPa, 0.6MPa, 0.8MPa, 1.0MPa, 1.25 MPa, and 1.6MPa.

Introduction of hot melt connection method of hdpe drain pipe

HDPE pipe hot-melt butt connection: First, place the two PE pipes to be installed and connected on the hot-melt fixture at the same time (the clamp can be replaced with the clamp according to the diameter of the pipe to be installed), and the other end of each pipe is supported by a pipe bracket up to the same level. The second is to use an electric rotary knife to cut the ends of the pipes flat to ensure that the contact surfaces of the two pipes can be fully matched. Then, the electric heating plate was heated to 210°C, placed in the middle of the end faces of the two pipes, and the electro-hydraulic device was operated to make the two end faces completely contact the electric heating plate for heating at the same time. After the final heating meets the requirements, remove the heating plate and operate the hydraulic device again, so that the end faces of the two melted pipes are fully connected and the hydraulic device is locked, in order to prevent rebound. In addition, the thickness of the pipe crimping and the docking time must strictly meet the material process requirements during heating. Generally, the technical parameters and specification requirements provided by the manufacturer can also be referred to.

121.webp)

894.webp)

318.webp)

874.webp)

855.webp)

347.webp)

476.webp)

420.webp)

720.webp)

294.webp)

146.webp)