Introduction

Poly pipes are commonly made from various types of polymer materials such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), cross-linked polyethylene (PEX), and polypropylene (PP). HDPE is a popular material for poly pipes due to its strength, durability, and resistance to corrosion and chemicals. LDPE is flexible and easy to install, but it is not as strong as HDPE and is often used for irrigation systems. PEX is a type of plastic tubing that is commonly used for radiant heating and plumbing systems. PP is a durable and heat-resistant material that is commonly used for hot and cold water supply lines.

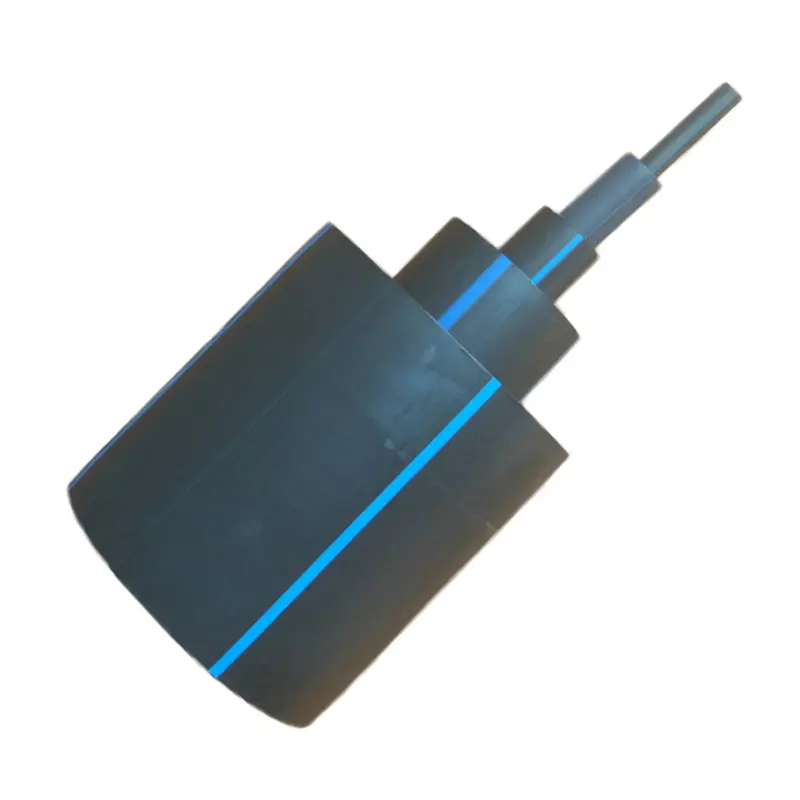

169382.webp)

Applications

Here are some common applications of HDPE water pipes:

1. Water supply systems

2. Gas distribution systems

3. Sewage and drainage systems

4. Industrial fluid transfer systems

5. Irrigation systems

6. Geothermal heating and cooling systems

7. Aquaculture systems

8. Firefighting systems

9. Mining operations for slurry and tailings transport

10. Land reclamation projects

11. Construction of new roads, highways, and bridges.

Specification

| Specification PE80 | |||||

| dn(mm) | SDR | ||||

| SDR33 | SDR21 | SDR17 | SDR13.6 | SDR11 | |

| PN,Mpa | |||||

| 0.4 | 0.6 | 0.8 | 1.0 | 1.25 | |

| en(mm) | |||||

| 0.4 | 0.6 | 0.8 | 1.0 | 1.25 | |

| 25 | - | - | - | - | 2.3 |

| 32 | - | - | - | - | 3.0 |

| 40 | - | - | - | - | 3.7 |

| 50 | - | - | - | - | 4.6 |

| 63 | - | - | - | 4.7 | 5.8 |

| 75 | - | - | 4.5 | 5.6 | 6.8 |

| 90 | - | 4.3 | 5.5 | 6.7 | 8.2 |

| 110 | - | 5.3 | 6.6 | 8.1 | 10.0 |

| 125 | - | 6.0 | 7.4 | 9.2 | 11.4 |

| 140 | 4.3 | 6.7 | 8.3 | 10.3 | 12.7 |

| 160 | 4.9 | 7.7 | 9.5 | 11.8 | 14.6 |

| 180 | 5.5 | 8.6 | 10.7 | 13.3 | 16.4 |

| 200 | 6.2 | 9.6 | 11.9 | 14.7 | 18.2 |

| 225 | 6.9 | 10.8 | 13.4 | 16.6 | 20.5 |

| 250 | 7.7 | 11.9 | 14.8 | 18.4 | 22.7 |

| 280 | 8.6 | 13.4 | 16.6 | 20.6 | 25.4 |

| 315 | 9.7 | 15.0 | 18.7 | 23.2 | 28.6 |

| 355 | 10.9 | 16.9 | 21.1 | 26.1 | 32.2 |

| 400 | 12.3 | 19.1 | 23.7 | 29.4 | 36.3 |

| 450 | 13.8 | 21.5 | 26.7 | 33.1 | 40.9 |

| 500 | 15.3 | 23.9 | 29.7 | 36.8 | 45.4 |

| 560 | 17.2 | 26.7 | 33.2 | 41.2 | 50.9 |

| 630 | 19.3 | 30.0 | 37.4 | 46.3 | 57.2 |

| 710 | 21.8 | 33.9 | 42.1 | 52.2 | - |

| 800 | 24.5 | 38.1 | 47.4 | 58.8 | - |

| 900 | 27.6 | 42.9 | 53.3 | - | - |

| 1000 | 30.6 | 47.7 | 59.3 | - | - |

| 1200 | 36.7 | 57.2 | 67.9 | - | - |

| 1400 | 42.9 | 66.7 | 82.4 | - | - |

| 1600 | 49.0 | 76.2 | 94.1 | - | - |

| Specification PE100 | |||||

| dn(mm) | SDR | ||||

| SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | |

| PN,Mpa | |||||

| 0.6 | 0.8 | 1.0 | 1.25 | 1.6 | |

| en(mm) | |||||

| 0.6 | 0.8 | 1.0 | 1.25 | 1.6 | |

| 32 | - | - | - | - | 3.0 |

| 40 | - | - | - | - | 3.7 |

| 50 | - | - | - | - | 4.6 |

| 63 | - | - | - | 4.7 | 5.8 |

| 75 | - | - | 4.5 | 5.6 | 6.8 |

| 90 | - | 4.3 | 5.5 | 6.7 | 8.2 |

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

| 125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

| 315 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 |

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

| 500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

| 560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.9 |

| 630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 |

| 710 | 27.2 | 33.9 | 42.1 | 52.2 | - |

| 800 | 30.6 | 38.1 | 47.4 | 58.8 | - |

| 900 | 34.4 | 42.9 | 53.3 | - | - |

| 1000 | 38.2 | 47.7 | 59.3 | - | - |

| 1200 | 45.9 | 57.2 | 67.9 | - | - |

| 1400 | 53.5 | 66.7 | 82.4 | - | - |

| 1600 | 61.2 | 76.2 | 94.1 | - | - |

Required Fittings

The required fittings for an HDPE water pipe depend on the specific application and the configuration of the system. However, some common fittings include:

1. Couplers: Couplers are used to join two pipes together and are available in a range of sizes to fit pipes of different diameters.

2. Elbows: Elbows are used to change the direction of the pipe, typically at a 90° or 45° angle.

3. Tees: Tees are used to join three pipes together at a T-junction.

4. Reducers: Reducers are used to connect pipes of different diameters and reduce the flow rate in the system.

5. Adapters: Adapters are used to connect the HDPE pipe to other types of piping materials or fittings, such as PVC or brass.

6. Valves: Valves are used to regulate the flow of water in the system and are available in a range of types, including ball valves, gate valves, and butterfly valves.

In addition to these fittings, specialty fittings may be required for specific applications, such as flange adapters for connection to pumps or valves. It is important to select the right fittings for the system to ensure proper installation and operation of the HDPE water pipe.

Is the poly pipe 1000 ft suitable for underground or above ground installation?

The suitability of a 2 inch poly pipe 1000 ft for underground or above ground installation depends on the type of material it is made from and its intended application. HDPE poly pipes are commonly used for underground water supply systems due to their strength and durability. LDPE poly pipes, on the other hand, are typically used for above-ground applications such as irrigation systems due to their flexibility and ease of installation. However, it is important to check with the manufacturer to determine the suitability of the poly pipe for your specific installation requirements to ensure proper performance and longevity of the system.

What is the recommended method of installation for the poly pipe, and are there any special considerations needed for installation in your specific location or application?

The recommended method of installation for poly pipe may vary depending on the specific application and manufacturer recommendations. However, some general guidelines for installing poly pipe include:

1. Preparing the trench or area where the pipe will be installed, removing any rocks, debris or sharp objects that could damage the pipe.

2. Making sure the pipe is straight and properly aligning the fittings.

3. Ensuring that the pipe is securely fastened to the fittings.

4. Burial depth for underground installation should meet local codes and be appropriate for the surrounding soil conditions.

5. Properly testing the system after installation to ensure there are no leaks and it is functioning correctly.

There may be additional considerations for installation depending on your location, such as local regulations or climatic conditions. Consult with the manufacturer or a professional installer to ensure that the installation process is appropriate for your specific application and location.

If you have any inquiry about HDPE Pipe and Fittings, Contact Us Now! Get A Free Quote Quickly!

Video

Click on the picture link to watch the product 2 inch poly pipe 1000 ft production video

FAQ

Q1: What is the diameter and length of the poly pipe?

A1: The poly pipe has a diameter of 2 inches (or approximately 5.08 centimeters) and a length of 1000 feet (or approximately 304.8 meters).

Q2: What is the material of the poly pipe?

A2: The poly pipe is typically made of high-density polyethylene (HDPE), which is a durable and flexible plastic material known for its resistance to corrosion, chemicals, and UV radiation.

Q3: What is the recommended application for a 2-inch poly pipe?

A3: The 2-inch poly pipe is commonly used for irrigation systems, agricultural applications, water distribution, and other fluid transfer purposes. It can handle moderate to high flow rates depending on the specific design and pressure rating.

Q4: What is the pressure rating of the poly pipe?

A4: The pressure rating of the poly pipe may vary depending on the specific brand and manufacturer. It is important to check the product specifications or consult the manufacturer to ensure the pipe is suitable for your intended application and operating pressure.

Q5: Is the poly pipe suitable for underground installation?

A5: Yes, the 2-inch poly pipe is commonly used for underground installations. It is resistant to soil and environmental conditions, making it suitable for long-term buried applications.

Q6: Can the poly pipe be used for both potable water and non-potable water systems?

A6: Yes, poly pipes are often approved for use in both potable and non-potable water systems. However, it is important to verify the specific pipe's certification and suitability for your intended use, especially for potable water applications.

Q7: Does the poly pipe require any special fittings or connectors?

A7: Yes, specific fittings and connectors designed for poly pipe systems are required for proper installation. These fittings are typically made of compatible materials like brass, stainless steel, or plastic and are available in various types, such as couplings, elbows, tees, and valves.

Q8: Is the poly pipe resistant to freezing temperatures?

A8: Poly pipes have some resistance to freezing temperatures, but they are not completely immune. Proper installation techniques, including burying the pipe below the frost line or insulating it, can help minimize the risk of freezing and subsequent pipe damage.

Please note that the above FAQs provide general information about 2-inch poly pipe with a length of 1000 ft. It is always recommended to consult the manufacturer's guidelines, local regulations, and industry standards for specific details and requirements related to your project.

495.webp)

231.webp)

109.webp)

344.webp)

554.webp)

476.webp)

420.webp)

720.webp)

294.webp)

146.webp)