The heating tool is made of metal, and a tubular resistance wire or heating element is installed inside the metal. The heating temperature of the tool surface is accurately controlled by a temperature sensor. To prevent the molten plastic from adhering to the tool surface, a layer of polytetrafluoroethylene is coated on the tool surface. All plastics that can be heated and melted can be welded by hot melt welding.

704060.webp)

Hot melt butt welding technology is generally used to connect pipes or pipe fittings with the same melt index (and preferably with the same SDR value). The welding parameters of different manufacturers are different, and users must strictly follow them.

204533.webp)

Butt welding is often used to connect pipes with larger diameters. The selected pressure should be able to generate the required force at the contact surface. When the butt welding machine has a hydraulic source, "force" is usually expressed as the applied hydraulic cylinder pressure.

1. Characteristics of hot melt welding

The characteristics of hot melt welding are: a dedicated hot melt welding machine is required: generally suitable for pipes with a nominal diameter greater than 90mm; suitable for connecting pipes and pipes of the same brand and different materials, and pipes and pipe fittings, but requires test verification; easily affected by environmental and human factors; high equipment investment; low connection cost; operators need to undergo special training and have certain experience.

Why use polyethylene pipes?

Light weight: PE plastic pipes are much lighter than cast iron pipes, which makes transportation and installation more convenient and reduces labor intensity.

Low water flow resistance: The inner wall of PE plastic pipes is smooth and has low water flow resistance, which is conducive to improving water delivery efficiency.

Easy and quick installation: PE plastic pipes have various and simple connection methods, such as hot melt connection, electric fusion connection, etc., which are fast to install and reduce construction difficulty and cost.

Low cost: The price of raw materials for PE plastic pipes is relatively low, and the production process is mature, making the overall cost lower than that of cast iron pipes.

Classification of polyethylene pipe welding machines

Polyethylene pipe welding machines are classified according to different construction purposes and functional principles as follows:

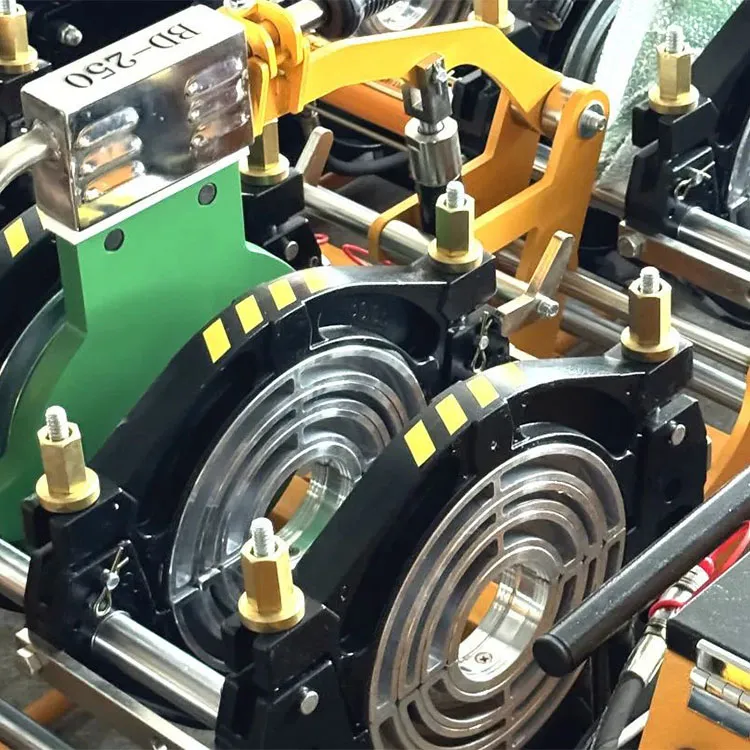

1. Butt fusion welding machine

(1)433990.webp)

1.1 Manual pressure-provided butt fusion welding machine

1.2 Hydraulic manual lifting hot plate butt fusion welding machine

1.3 Hydraulic automatic lifting hot plate butt fusion welding machine

1.4 Hydraulic parameter tracking butt fusion welding machine

1.5 Hydraulic fully automatic butt fusion welding machine

2. Electric fusion welding machine

297131.webp)

1.1 Simple transformer electric fusion welding machine

1.2 Manual digital control electric fusion welding machine

1.3 Semi-automatic electric fusion welding machine

1.4 Fully automatic electric fusion welding machine

939.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)