Introduction about Inner rib HDPE pipes

Inner rib HDPE pipes have a rib on the inside of the pipe wall, which provides additional structural support and helps to resist lateral movement. This design is often used in situations where the pipe will be subjected to high levels of external loading, such as in underground applications or in areas with unstable soil conditions. Inner rib pipes are also more resistant to deformation and are generally more durable than external rib pipes. Additionally, inner rib pipes typically have a higher pressure rating than external rib pipes, as the rib provides additional support to withstand higher pressures. However, inner rib pipes are typically more expensive than external rib pipes due to the additional manufacturing process required to create the rib, and they are generally more rigid and less flexible, making them more difficult to install in certain situations.

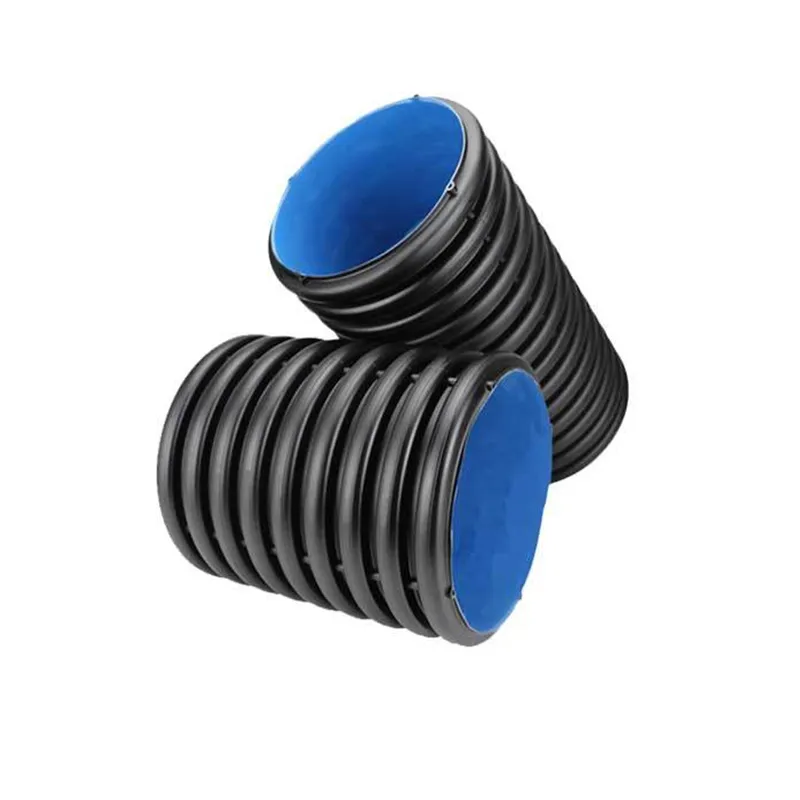

The most common Inner rib HDPE pipes: Corrugated HDPE pipe

One type of inner rib HDPE pipe that is particularly popular in the construction and infrastructure industries is Inner Rib Corrugated HDPE pipe. This type of pipe has a corrugated design in addition to the inner rib, which helps to increase its strength and flexibility. Inner Rib Corrugated HDPE pipes are resistant to corrosion and chemicals, and can withstand high levels of pressure without breaking or cracking, making them an ideal choice for use in a variety of applications, including water and sewage systems, stormwater drainage, and irrigation systems. They are also easy to install, as they are lightweight and flexible and can be easily connected using fittings and couplers.

External rib HDPE pipes

External rib HDPE pipes, on the other hand, have a rib on the outside of the pipe wall. This design is typically used in situations where the pipe will be buried shallowly or where there are not significant external loads acting on the pipe. External rib pipes are generally easier to install than inner rib pipes, as they are more flexible and can be bent more easily. This can make them a good choice for situations where the pipe needs to follow a specific route or bend around obstacles. However, external rib pipes are not as durable as inner rib pipes and may be more prone to deformation or damage under certain conditions. They are also typically less resistant to external loads, such as the weight of the soil or the weight of vehicles driving over the pipe.

Conclusion

Overall, the choice between inner rib and external rib HDPE pipes will depend on the specific application and the conditions in which the pipe will be used. Inner rib pipes, including Inner Rib Corrugated HDPE pipes, are generally more durable and resistant to deformation, but may be more difficult to install and more expensive. External rib pipes are easier to install, but may not be as durable under certain conditions. It is important to carefully consider the needs of the specific application and the potential benefits and drawbacks of each type of pipe before making a decision.

939.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)