Common types of metal seamless pipe fittings include

Seamless pipe: a pipe without welding gaps, usually produced by extrusion, stretching and other processes.

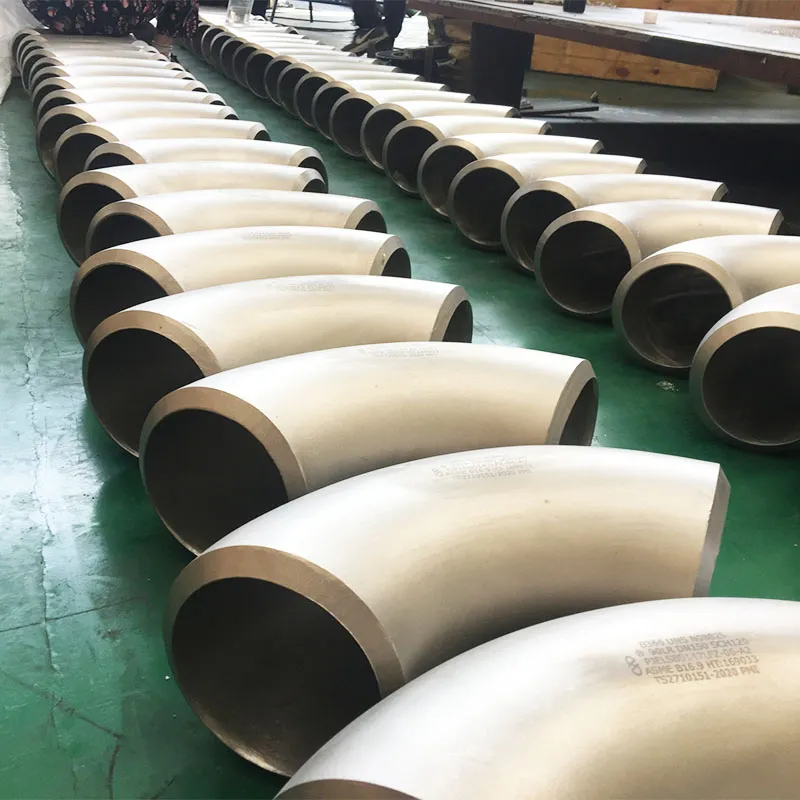

Elbow: a pipe fitting that changes the direction of the pipeline, with common angles of 45°, 90°, 180°, etc.

Tee: a pipe fitting used to connect three pipes.

Flange: a device used to connect pipelines to equipment, valves, etc.

Pipe cap: a pipe fitting used to close the end of a pipeline.

Joint: a fitting that connects two pipes.

1. Metal pipe fitting manufacturing process

1) Seamless elbow

Elbow is a pipe fitting used at the bend of the pipeline. Among all the pipe fittings used in the pipeline system, it accounts for the largest proportion, about 80%. Usually, different forming processes are selected for elbows of different materials or wall thicknesses. Common seamless elbow forming processes used by manufacturers include hot pushing, stamping, extrusion, etc. The hot pushing elbow forming process uses a special elbow pushing machine, a core mold and a heating device to make the blank on the mold move forward under the push of the pushing machine, and is heated, expanded and bent during the movement. The deformation characteristics of the hot pushing elbow are that the diameter of the tube billet is determined according to the law that the volume of the metal material remains unchanged before and after plastic deformation. The diameter of the tube billet used is smaller than the diameter of the elbow. The deformation process of the billet is controlled by the core mold, so that the compressed metal at the inner arc flows and compensates to other parts that are thinned due to the expansion of the diameter, thereby obtaining an elbow with uniform wall thickness. The hot pushing elbow forming process has the characteristics of beautiful appearance, uniform wall thickness and continuous operation, which is suitable for mass production. Therefore, it has become the main forming method for carbon steel and alloy steel elbows, and is also used in the forming of stainless steel elbows of certain specifications. The heating methods of the forming process include medium frequency or high frequency induction heating (the heating coil can be multiple coils or single coil), flame heating and reverberatory furnace heating. The heating method used depends on the requirements of the formed product and the energy situation. Stamping elbows are the earliest forming process used in mass production of seamless elbows. At present, it has been replaced by hot pushing or other forming processes in the production of elbows of common specifications. However, it is still used in elbows of certain specifications due to small production quantities, too thick or too thin wall thickness and special requirements. The stamping of elbows uses a tube blank with the same outer diameter as the elbow, and uses a press to directly press it in the mold. Before stamping, the tube blank is placed on the lower die, the inner core and the end die are loaded into the tube blank, and the upper die moves downward to start pressing. The elbow is formed by the constraint of the outer die and the support of the inner die. When the stamping elbow is formed, the outer arc is in a stretched state, and there is no excess metal in other parts to compensate, so the wall thickness at the outer arc is thinned by about 10%. However, due to its suitability for single-piece production and low cost, the stamping elbow process is mostly used for the manufacture of small batches and thick-walled elbows. Stamping elbows are divided into cold stamping and hot stamping. Usually, cold stamping or hot stamping is selected according to the material properties and equipment capacity.

The forming process of cold extruded elbows is to use a special elbow forming machine to put the tube blank into the outer mold. After the upper and lower molds are closed, the tube blank moves along the gap reserved by the inner and outer molds under the push of the push rod to complete the forming process. The elbows manufactured by the cold extrusion process of inner and outer molds have beautiful appearance, uniform wall thickness and small dimensional deviation. Therefore, this process is often used for stainless steel elbows, especially thin-walled stainless steel elbows. The inner and outer molds used in the process have high precision requirements; the wall thickness deviation requirements of the tube blank are also relatively stringent.

2) Seamless tee uses seamless pipes to manufacture tees.

At present, the commonly used processes are hydraulic bulging and hot pressing. Tee hydraulic bulging is a forming process that expands the branch pipe through axial compensation of metal materials. The process is to use a hydraulic press to inject liquid into a tube with the same diameter as the tee, and squeeze the tube through the synchronous centering movement of the two horizontal side cylinders of the hydraulic press. The tube volume decreases after being squeezed, and the pressure of the liquid in the tube increases as the tube volume decreases. When the pressure required for the tee branch to bulge out is reached, the metal material flows along the inner cavity of the mold under the dual action of the side cylinder and the liquid pressure in the tube and bulges out the branch. The hydraulic bulging process can be formed in one time, with high production efficiency, and the wall thickness of the main tube and shoulder of the tee is increased. Because the equipment tonnage required for the hydraulic bulging process of seamless tees is large, it is currently mainly used in the manufacture of standard wall thickness tees less than DN400 in China. The applicable forming materials are low-carbon steel, low-alloy steel, stainless steel with relatively low cold hardening tendency, including some non-ferrous metal materials such as copper, aluminum, titanium, etc.

The hot pressing forming of tees is to flatten the tube billet larger than the diameter of the tee to about the size of the tee diameter, and open a hole at the location of the stretched branch pipe; the tube billet is heated, placed in the forming die, and the punch die for stretching the branch pipe is installed in the tube billet; the tube billet is radially compressed under the action of pressure, and the metal flows in the direction of the branch pipe during the radial compression process and forms the branch pipe under the stretching of the punch die. The whole process is formed by the radial compression of the tube billet and the stretching process of the branch pipe. Unlike the hydraulic bulging tee, the metal of the hot pressing tee branch pipe is compensated by the radial movement of the tube billet, so it is also called the radial compensation process. Due to the use of heating and pressing the tee, the tonnage of equipment required for material forming is reduced. Hot pressing tees have a wide adaptability to materials and are suitable for low carbon steel, alloy steel, and stainless steel materials; especially for tees with large diameters and thick walls, this forming process is usually used.

2. Main inspection items for metal seamless pipe fittings

Metal pipe fittings generally have factory inspection items such as raw material inspection, surface quality, shape and size, hardness inspection, non-destructive testing, and water pressure testing. Some trial products of pipe fittings also require burst test items. The inspection items of different pipe fittings shall be carried out in accordance with the corresponding product standards.

939.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)