1. PE solid wall drainage pipe

1.1 Product Overview

PE solid wall pipe is the most basic PE drainage pipe. The pipe wall is a uniform solid structure with no internal cavity. It is consistent inside and outside. It is usually made of high-density polyethylene (HDPE) or low-density polyethylene (LDPE).

1.2 Main features

The pipe wall is thick and has strong pressure bearing capacity. It can be used for drainage pipes with a certain pressure.

It has strong corrosion resistance and can resist erosion by chemical media such as acid and alkali.

The inner wall is smooth, the friction coefficient is small, and the water flow resistance is small.

It is easy to construct and can be connected by hot melt butt welding, electric fusion connection, etc., with high connection reliability.

1.3 Applicable scenarios

Building drainage (indoor and outdoor drainage pipes)

Industrial sewage (transporting corrosive wastewater)

Rainwater discharge (small municipal pipe network)

1.4 Specification range

Diameter: DN20 DN1200

Pressure level: PN6, PN8, PN10, PN16

Color: black, blue, orange, white, etc.

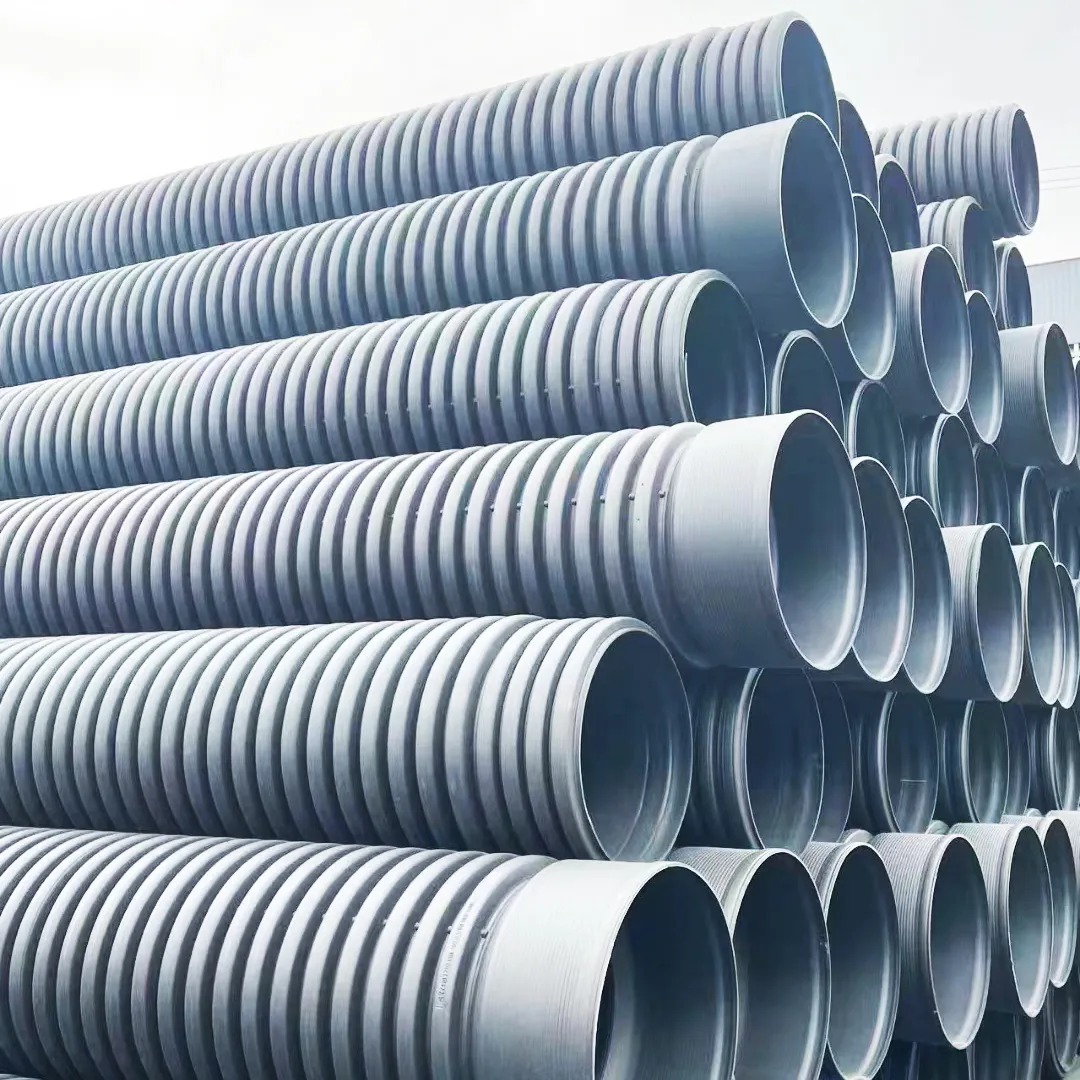

2. HDPE double-wall corrugated pipe

2.1 Product Overview

HDPE double-wall corrugated pipe adopts a double-layer structure design: the outer wall is corrugated to enhance strength, and the inner wall is smooth to reduce fluid resistance. It is a lightweight and high-strength drainage pipe, widely used in underground drainage systems.

2.2 Main features

High strength and superior compressive performance: the corrugated outer wall structure greatly improves the ring stiffness of the pipe and can withstand greater soil pressure.

Lightweight and convenient: lighter than traditional cement pipes, more economical to transport and construct.

Strong corrosion resistance: HDPE material itself is resistant to acid and alkali corrosion and not easy to age.

Smooth inner wall and smooth drainage: low friction coefficient, improve fluid delivery efficiency.

Flexible connection: socket-type rubber ring connection, easy construction and good sealing performance.

2.3 Applicable scenarios

Municipal drainage (rainwater pipe network, sewage treatment system)

Highway/railway drainage (underground drainage pipe)

Farmland drainage (irrigation and drainage projects)

2.4 Specification range

Diameter: DN110 DN2000

Ring stiffness grade: SN4, SN8, SN10, SN12.5, SN16

Color: black, yellow, blue, etc.

3. HDPE hollow wall winding pipe (carat pipe)

3.1 Product Overview

HDPE hollow wall winding pipe (also known as carat pipe) is manufactured by spiral winding process, the pipe wall is a multi-layer structure, and a hollow cavity is formed to enhance the strength and durability of the pipe.

3.2 Main features

Large diameter drainage capacity: the pipe diameter can reach DN3000, suitable for large flow drainage projects.

Lightweight and convenient construction: lighter than cement pipes of the same specifications, with low installation cost.

High ring stiffness: can withstand higher external pressure, suitable for deep buried projects.

Corrosion resistance and long service life: HDPE material has excellent corrosion resistance and can last for more than 50 years.

Good welding sealing: hot melt butt welding or electric fusion welding is used to ensure that the pipeline is leak-free.

3.3 Applicable scenarios

Large-scale municipal drainage (rainwater and sewage transportation)

Sponge city construction (rainwater storage system)

Industrial sewage treatment (chemical wastewater discharge)

3.4 Specification range

Diameter: DN300 DN3000

Ring stiffness grade: SN8, SN10, SN12.5, SN16

Color: black, blue

4. Steel belt reinforced spiral corrugated pipe

4.1 Product Overview

Steel belt reinforced spiral corrugated pipe is to add a steel belt reinforcement layer to the HDPE pipe structure to improve the ring stiffness of the pipe, making it suitable for drainage projects with higher loads.

4.2 Main features

Ultra-high strength: The steel belt reinforced structure provides higher compressive resistance, suitable for deep burial and high load applications.

Impact resistance and corrosion resistance: The HDPE layer provides excellent corrosion resistance and is not easily corroded by chemicals.

Large-diameter conveying capacity: DN300 DN2400 specifications can be manufactured to meet large-flow drainage needs.

Good flexibility: It can adapt to ground subsidence and prevent cracking or leakage.

Easy construction: It adopts electric fusion connection and socket connection, which is quick to install.

4.3 Applicable scenarios

High-load municipal drainage system (urban trunk drainage network)

Large industrial sewage treatment (petrochemical, papermaking, metallurgical industry wastewater transportation)

Underground culvert drainage (culvert, tunnel drainage)

4.4 Specification range

Diameter: DN300 DN2400

Ring stiffness grade: SN8, SN10, SN12.5, SN16, SN20

Color: black, blue, orange

| Type | Structural features | Strength | Applicable scenarios | Connection |

| PE solid wall pipe | Solid wall | Higher | Building drainage, industrial sewage | Butt fusion, electric fusion |

| HDPE double wall corrugated pipe | Outer corrugation + inner smooth | High | Municipal drainage, highway drainage | Socket rubber ring connection |

| HDPE hollow wall spiral pipe | Hollow cavity reinforcement | Higher | Large-scale municipal drainage and sewage treatment | Hot melt welding |

| Steel belt reinforced spiral corrugated pipe | Steel belt reinforcement | Super | High pressure drainage, industrial sewage | Electric fusion connection, socket connection |

639.webp)

194.webp)

328.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)