About PERT II pipes

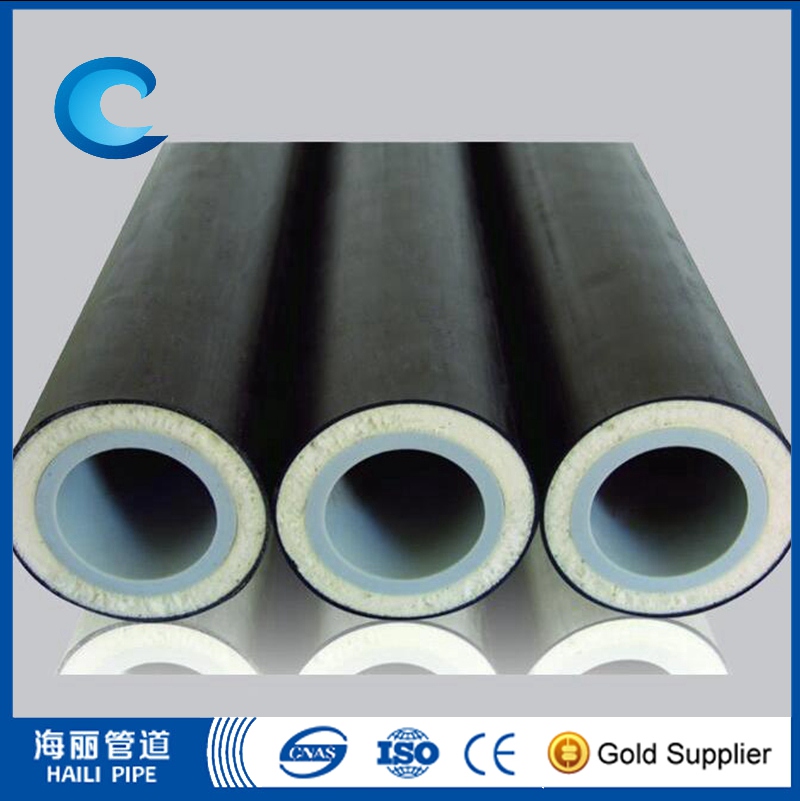

PERT II is a direct buried prefabricated thermal insulation thermal pipeline with good thermal insulation performance, temperature resistance of 95℃, safety and reliability, and low engineering cost.

The service life of PERT II insulation pipes is generally about 40-50 years.

The color of the polyurethane PU foam layer and the heat-resistant polyethylene pipe of PERTIl is the original color of the raw material, which effectively eliminates the addition of fillers and ensures the purity and quality of the PERT II pipe.

Product parameters for PERT II pipes

Name: PERTII pipes

Material: PE, Hexene, and C4H8

Pressure Rating: 0.8MPa, 1.0MPa,1.6MPa, 2.0MPa

Size: dn25mm ~ 630mm

Standard: GB/T28799-2012, CJ/T480-2015(HAILI is main drafter of this certificate)

Colors: Black

Applications:Indoor heating

Service Life: 40-50 years

Working Temperature: 90℃

Payment items: T/T L/C

Port: Qingdao

Pipe Connection: electrofusion, butt fusion, flange fusion

Features of our PERT II pipes

1. Low temperature brittleness resistance.

PERTII type pipe itself belongs to the modified type of PE series. Therefore, it is similar to the PE structure in the whole structure, and the low temperature brittleness is as low as -40°C.

2. Excellent high temperature resistance.

The long-term use temperature of PERTII is 95 ℃. The pipe has outstanding anti-aging ability. At any temperature (up to 110°C), the hydrostatic predicted strength curve before 8760H has no inflection point, and the pipeline has no brittle failure

3. Strong pressure bearing capacity.

Long-term delivery of 70 ℃ hot water under the conditions of use.

4. Various construction methods.

PERT pipe is thermoplastic, so in connection, the products can be connected to each other by heating, and the products can be recycled.

5. Hot-melt butt joint.

Mainly for pipes and fittings above DN63; hot-melt socket, mainly for pipes and fittings below DN63; electrofusion connection, suitable for DN20-DN250 pipes and fittings.

6. The project cost is low.

The PE-RTII heating pipe with HDPE as the protective layer is safe and stable. Light weight, convenient construction, low construction cost, long service life, and low maintenance cost.

7. Reduce heat loss and save energy.

The thermal conductivity of polyurethane material is lower than other thermal insulation materials, and the thermal insulation effect is increased by 4-9 times. The overall heat loss of the heating pipeline is greatly reduced, and it is easier to realize that the heat loss of the heating network is less than the national standard requirement.

8. Anti-corrosion, good insulation performance, long service life.

The polyurethane rigid foam insulation layer is tightly bonded to the outer layer of the working pipe, which isolates the infiltration of air and water and plays a good anti-corrosion effect. At the same time, the HDPE protective layer has good anti-corrosion, insulation and mechanical properties. The service life of the inner PE-RTII working tube can reach 50 years.

9. Less land occupation and quick construction, which is beneficial to environmental protection.

There is no need to build large trenches, only the product needs to be buried underground, which greatly reduces the land occupation of the project, reduces the amount of earthwork excavation by more than 50%, and reduces the amount of civil work and concrete by 90%. In addition, the processing of the insulation pipe and the on-site trenching are carried out in parallel, and only on-site joints are required, which can shorten the construction period by more than 50%.

Application of our PERTII thermal pipeline

1. Urban central heating secondary pipe network, hot spring water insulation pipe.

2. Solar water heating project of air energy heat pump hot water engineering plant.

3. Hotel, guesthouse air energy heat pump hot water project Hotel, guesthouse solar hot water project.

4. Hotel, hair salon air energy heat pump hot water project Hotel, hair salon solar water heating project.

5. School air energy heat pump hot water engineering school solar hot water project.

6. Hospital air energy heat pump hot water project Hospital solar water heating project.

7. Sauna foot bathing air energy heat pump hot water project Sauna, foot bathing solar water heating project.

8. Apartment air energy heat pump hot water project apartment solar water heating project.

9. Villas, resorts, leisure center air energy heat pump hot water project Villa, resort, leisure center solar water heating project.

10. Building energy-saving air-energy heat pump hot water project building solar water heating project building hot water project.

990.webp)

288.webp)

294.webp)

476.webp)

420.webp)

146.webp)