The Rise of SRTP Pipes: Revolutionizing Modern Infrastructure

What are SRTP Pipes?

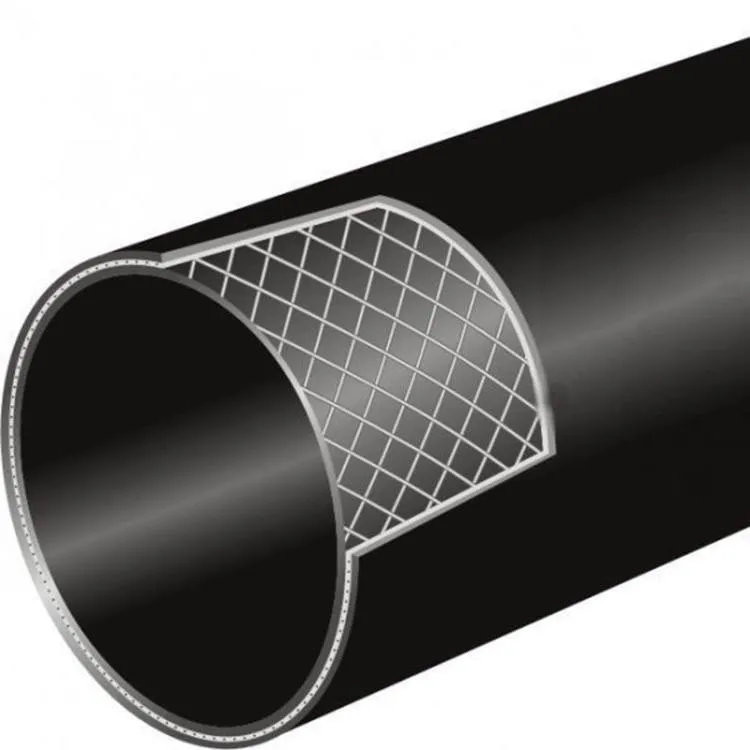

SRTP pipes are a type of composite pipe that integrates the strength of steel with the corrosion resistance and flexibility of thermoplastic materials. The core of an SRTP pipe typically consists of a steel wire mesh, which provides exceptional strength and pressure resistance. This steel core is then encapsulated in layers of high-density polyethylene (HDPE) or other thermoplastic materials, creating a robust yet flexible pipe.

Key Characteristics of SRTP Pipes

1. High Strength and Durability

The steel reinforcement provides SRTP pipes with exceptional tensile strength, allowing them to withstand high internal pressures. This makes them suitable for applications that require long-term durability and reliability.

2. Corrosion Resistance

Unlike traditional metal pipes, SRTP pipes are highly resistant to corrosion. The thermoplastic layers protect the steel core from moisture and chemicals, ensuring a longer lifespan and reducing maintenance costs.

3. Flexibility and Lightweight

SRTP pipes are lighter than traditional steel pipes, making them easier to handle and install. Their flexibility allows for easy maneuvering around obstacles and reduces the need for extensive jointing and fittings.

4. Thermal Resistance

These pipes exhibit excellent thermal resistance, making them suitable for use in a wide range of temperatures. They can efficiently handle both hot and cold fluids without compromising their structural integrity.

Benefits of SRTP Pipes

1. Cost-Effectiveness

The long lifespan and reduced maintenance requirements of SRTP pipes translate to significant cost savings over time. Additionally, their lightweight nature reduces transportation and installation costs.

2. Environmental Sustainability

The use of thermoplastic materials in SRTP pipes makes them more environmentally friendly compared to traditional metal pipes. They are recyclable and produce fewer emissions during manufacturing.

3. Enhanced Safety

The corrosion resistance and durability of SRTP pipes enhance the safety of the systems they are used in. This is particularly important in applications involving potable water and hazardous chemicals.

4. Versatility

SRTP pipes can be used in a variety of applications, including water supply and distribution, sewage and drainage systems, industrial pipelines, and even in the transportation of gases.

Applications of SRTP Pipes

1. Water Supply Systems

SRTP pipes are increasingly being used in municipal water supply systems due to their durability, corrosion resistance, and ability to handle high pressures. They ensure a reliable and safe water supply to urban and rural areas.

2. Sewage and Drainage

The flexibility and corrosion resistance of SRTP pipes make them ideal for sewage and drainage systems. They can efficiently transport wastewater while minimizing the risk of leaks and blockages.

3. Industrial Applications

In industrial settings, SRTP pipes are used for transporting chemicals, gases, and other fluids. Their ability to withstand harsh environments and high pressures makes them a preferred choice in various industries.

4. Oil and Gas

The oil and gas industry benefits from the high strength and corrosion resistance of SRTP pipes, which are used for transporting petroleum products, natural gas, and other related materials.

SRTP pipes represent a significant advancement in pipeline technology, offering a compelling combination of strength, durability, and flexibility. Their numerous benefits and versatile applications position them as a valuable solution for modern infrastructure challenges. As urbanization and industrialization continue to drive the demand for efficient and reliable piping systems, SRTP pipes are poised to play a crucial role in shaping the future of infrastructure development.

659.webp)

210.webp)

328.webp)

294.webp)

476.webp)