Introduction:

When it comes to plumbing, there are many materials to choose from for piping. Among the popular materials are PVC, Copper, CPVC, PEX, and PPR. In this article, I will focus on the differences between two of them, PEX and PPR. PEX (cross-linked polyethylene) and PPR (Polypropylene Random Copolymer) are both types of plastic pipes that are used extensively in plumbing systems. Generally, both PEX and PPR pipes are safe for use in residential plumbing systems. However, there are distinct differences between the two that consumers should consider when choosing between them. Here I will discuss PEX and PPR Pipes, their pros and cons, and how to choose the right one for your project.

Properties of PEX Pipes:

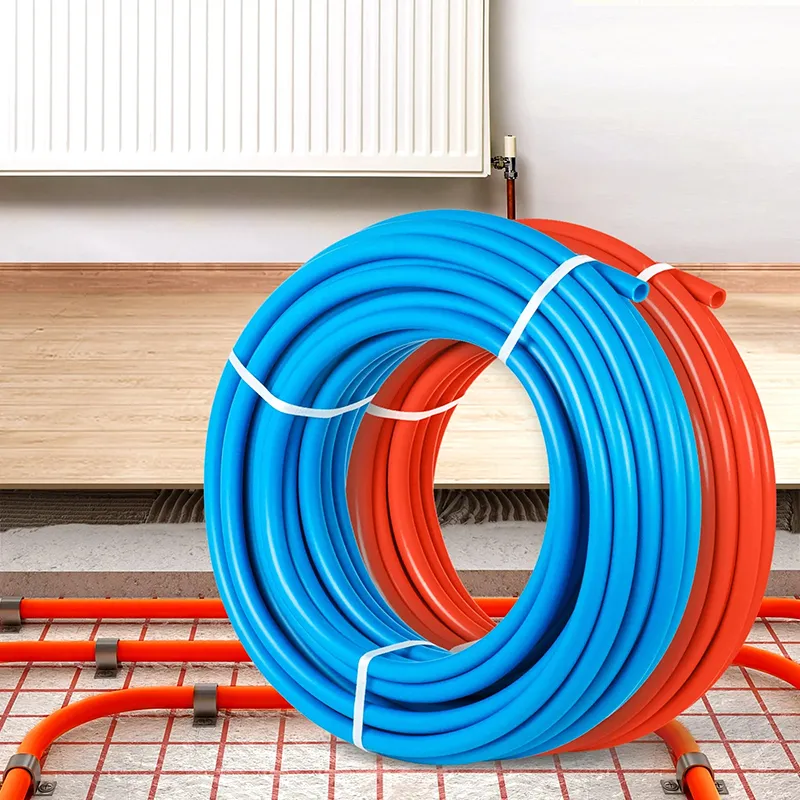

PEX pipes are made of high-density polyethylene (HDPE) and they are cross-linked with either heat or chemicals. The cross-linking improves the properties of PEX pipes and makes them more flexible, durable and resistant to high temperatures and pressure. Cross-linking helps PEX pipes to remain stable under extreme conditions, such as high temperature exposure or freezing temperatures. PEX pipes are available in different sizes ranging from 1/4 inch to 4 inches and are color-coded according to the intended use. Red PEX pipes are for hot water while blue pipes are for cold water. PEX can be installed using either crimping, cinch clamps, press-fit, or expansion fittings. Because of their flexibility, PEX pipes can curve around obstructions in walls or floors, making them ideal for retrofit projects where space may be limited.

Properties of PPR Pipes:

PPR pipes are made from polypropylene (PP), which is a thermoplastic polymer. PPR pipes have superior mechanical properties and a high-temperature resistance compared to other plastic pipes. PPR pipes come in different sizes ranging from 1/2 inch to 12 inches and are color-coded according to the intended use. Green PPR pipes are for cold water while red pipes are for hot water. PPR pipes use heat fusion methods to join pipe sections together. Once fused, PPR pipes create a joint that is as strong as the original pipe and will not leak, making them suitable for installation in a wide range of applications. PPR pipes are also resistant to chemicals, corrosion, and UV radiation.

Advantages of PEX Pipes:

1. Flexibility: PEX pipes are incredibly flexible, allowing them to take on complex shapes as they curve around obstacles in walls and floors.

2. Lower Cost: PEX pipes are cheaper than copper pipes, making them an ideal choice for budget-conscious consumers.

3. Easy Installation: Installation of PEX pipes is fast and easy, as they can be cut to length using a simple pipe cutter, and installed with crimp, cinch clamp, press-fit, and expansion fittings.

4. Durability: PEX pipes are highly durable and have excellent resistance to corrosion. They can last up to fifty years if properly installed and maintained.

5. Thermal Properties: PEX pipes are incredibly resistant to extreme temperatures and pressure changes, making them suitable for hot and cold water supply.

Advantages of PPR Pipes:

1. Sustainability: PPR pipes are recyclable, making them an eco-friendly choice.

2. Resistance to chemicals: PPR pipes are highly resistant to chemicals, acids, alkalis, and many other substances used in plumbing systems.

3. High-Temperature Resistance: PPR pipes have high-temperature resistance, making them suitable for hot water supply systems.

4. Easy Joining: PPR pipes are fused together using heat fusion techniques, creating a mechanical bond that is as strong as the original pipe.

5. Leak-Free Joints: PPR pipes’ heat fusion joints are leak-free, ensuring that the plumbing system remains stable and reliable.

Disadvantages of PEX Pipes:

1. Susceptibility to UV Light: PEX pipes can be damaged by prolonged exposure to UV radiation, which can lead to cracking.

2. Chemical Compatibility: PEX pipes may not be compatible with certain chemicals or substances used in some plumbing systems, such as chlorine, which can cause the pipe to deteriorate.

3. Fittings: PEX pipes require special fittings to be installed, which can add to the installation cost.

4. Bursting: PEX pipes may burst if they are subjected to water hammer or high-pressure changes.

Disadvantages of PPR Pipes:

1. Rigidity: PPR pipes are rigid and inflexible, making them challenging to install around obstacles in walls or floors.

2. Higher Cost: PPR pipes are more expensive than PEX pipes.

3. Installation: PPR pipes require a heat fusion machine and special fusion fittings, making them more difficult to install.

4. Brittle: PPR pipes can become brittle if exposed to low temperatures, which can lead to cracking or fracture.

Choosing Between PEX and PPR Pipes:

When choosing between PEX and PPR pipes, consider the following factors:

1. Application: Consider the intended use for the pipes, whether it is for hot or cold water supply, or for drainage or sewer systems.

2. Budget: PEX pipes are generally cheaper than PPR pipes, making them an ideal choice for budget-conscious consumers.

3. Installation: PEX pipes are easier to install than PPR pipes, making them the preferred choice for DIY homeowners.

4. Environment: Consider the environment where the pipes will be installed. PEX pipes are more susceptible to UV radiation, while PPR pipes can become brittle in low temperatures.

Conclusion:

PEX and PPR pipes are both excellent choices for plumbing systems. Both types of pipes have their own advantages and disadvantages, and the choice largely depends on the specific needs of the project. PEX pipes are more flexible and easier to install, making them suitable for tight spaces and retrofit projects. PPR pipes are rigid and durable, making them ideal for industrial and commercial applications. When choosing between the two, consider factors such as application, budget, installation, and environment. Consulting with a professional plumber can also help in choosing the right type of pipe for your project.

249.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)