As one of the important components of urban infrastructure, municipal pipelines can timely remove rainwater from the city surface, provide industrial and domestic water for the city, and prevent urban water resources from being polluted.

I. Pipeline materials

1.Basic requirements

Sufficient strength and certain rigidity. The inner wall of the pipeline is smooth to reduce water flow resistance. It has a certain corrosion resistance. It has sufficient airtightness. It is easy to process and economical.

2. Commonly used pipes

(1) Concrete pipes and reinforced concrete pipes. High strength and convenient material acquisition; poor acid and alkali resistance and impermeability, many joints, heavy weight, and easy to break during transportation. Suitable for areas with poor soil quality and when crossing railways and roads. Pipe mouth form: socket, flat mouth, tongue and groove

739804.webp)

(2) Clay pipe. After glazing, the pipe wall is smooth, impermeable and corrosion-resistant; it is fragile and has low strength. It is suitable for removing acidic industrial wastewater or corrosive groundwater. Pipe mouth form: socket, flat mouth

713692.webp)

(3) Metal pipe. High strength, impermeability, smooth pipe wall, few joints; high price and easy to corrode. Applicable to areas with high seismic resistance, high groundwater level, high pressure, severe sand flow, or particularly high leakage requirements. Pipe mouth form: flange, socket n Common pipe materials: steel pipe, cast iron pipe

(4) Plastic pipes are easy to construct, light in material, and have smooth inner walls; they have low strength, poor rigidity, large thermal expansion and contraction, and are easy to age under sunlight. Pipe mouth connection: bonding, electric fusion welding Common pipe materials: UPVC hard polyvinyl chloride, PE polyethylene, PP polypropylene.

(5) New pipes n HDPE high-density polyethylene, FRP fiberglass, glass fiber concrete, etc.

3. Water supply pipe fittings

① Accessories n Used at the bends, branches, diameter changes, and connections to other equipment in the pipeline, such as: tees, crosses, elbows, reducers (reducers), short pipes (variable interfaces), etc.

② Accessories Water distribution control check valve: control water flow in only one direction to prevent backflow

Exhaust valve: gas in the rib pipe, reduce water flow resistance Drain valve: empty the pipe and remove sediment Fire hydrant: fire truck water intake facility

II. Pipeline structure

1. Foundation includes: foundation, foundation, pipe seat

660995.webp)

316078.webp)

① Sand foundation Arc-shaped plain soil foundation, sand cushion foundation

Applicable to areas with very good soil conditions and no groundwater, pipes with a pipe diameter of less than 600mm, pipes with a pipe top soil thickness of 0.7-2.0m, secondary pipes and temporary pipes not under the roadway.

377600.webp)

② Concrete pillow foundation Concrete pads are set under the pipe interface

Applicable to areas with good soil conditions and no groundwater, water supply and drainage branches.

699609.webp)

③ Concrete strip foundation Lay strip cement concrete along the entire length of the pipeline

Applicable to various soil types, especially poor soil conditions, earthquake zones, important pipelines, etc. According to the form of the pipe seat, there are four types of pipe seat foundations: 90 degrees, 135 degrees, 180 degrees, and 360 degrees. The foundations are selected according to the buried depth of the pipe.

214521.webp)

2. Drainage pipe ancillary structures

(1) Inspection wells

Function: to facilitate the connection of pipes and regular inspection and dredging.

Location: at the intersection of pipes, bends, places where the size or slope changes, waterfalls, and straight sections at a certain distance.

Structure: It consists of the bottom of the well, the well body, and the well cover.

942700.webp)

Well bottom

Generally, low-grade concrete is used, and the foundation is made of crushed stones, pebbles or concrete; it is advisable to set up a flow channel, and make the bottom of the flow channel have a certain slope to reduce water flow resistance and prevent siltation; there should be a width of not less than 20 cm between the two sides of the flow channel and the well wall, so that maintenance personnel can stand when going down the well, that is, the ditch shoulder.

617550.webp)

Well body

It can be built with bricks or stones, or reinforced concrete can be cast in place. For shallow inspection wells that do not require descent, the well body is a straight-walled cylindrical well body; for those that require descent, the well body is structurally divided into three parts: well chamber, tapered portion, and well shaft. The well chamber diameter is not less than 1m, and the well shaft diameter is not less than 0.7m. The well chamber and well shaft are connected by a tapered portion. A reinforced concrete cover plate can also be added to the well chamber, and the well shaft can be built on the cover plate.

680071.webp)

Well cover

It consists of a well cover and a cover seat, and is usually made of cast iron, reinforced concrete, etc. To prevent rainwater from flowing in, the cover top should be slightly higher than the ground.

(2) Rainwater inlet

Function: Collect rainwater from surface runoff and direct it into the rainwater pipe.

Location: Road intersection, a certain distance (25-50m) on a straight line, and low-lying areas near curbstones.

Structure: It consists of a foundation, well grate, well shaft, and connecting pipe.

976763.webp)

4. Auxiliary structures of water supply pipelines

(1) Valve well

Function: Install various water supply pipeline accessories to facilitate operation and maintenance.

(2) Drain valve well

Function: drain the water discharged by the drain valve, composed of a wet well and a valve well.

(3) Pier

Function: prevent the socket joint of the pipe from falling off due to excessive water thrust.

Location: elbow, tee, reducer, etc.

III. General provisions of pipeline engineering drawings

1. Elevation

The standard stipulates that the absolute elevation should be marked for outdoor projects; when there is no absolute elevation, the relative elevation can also be marked.

The pressure pipe should be marked with the pipe center elevation

The ditch and gravity pipe should be marked with the ditch (pipe) bottom elevation

2. Pipe diameter

Nominal diameter: DN, commonly used for metal pipes.

For example, the outer diameter of the cast iron pipe DN25 is D×δ, commonly used for stainless steel pipes and seamless steel pipes.

For example, the inner diameter of the stainless steel pipe D108×4 is d, commonly used for concrete pipes, clay pipes, etc.

For example, the reinforced concrete pipe d300s

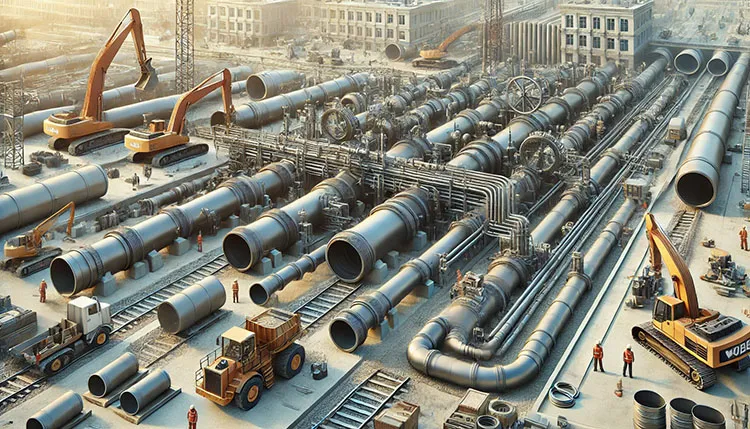

Municipal pipelines are a key component of urban infrastructure, involving water supply, discharge, urban drainage systems and support for various other public services. They ensure the normal operation of the city and safeguard all aspects of residents' lives through underground pipeline networks. The following is a detailed introduction to municipal pipelines:

Types of municipal pipelines

1.Water supply pipeline

Water supply pipelines are the core component of the urban water supply system, responsible for transporting water to users through pipelines. The design and construction of water supply pipelines take into account the source of water, the pressure bearing capacity of the pipeline, the corrosion resistance of the pipeline material and the geographical environment of the water supply area.

Common materials

Steel pipe: High strength, suitable for high-pressure environment, but easy to corrode, requiring anti-corrosion treatment.

Plastic pipe (such as PE, PVC pipe): Corrosion-resistant, light weight, easy to install, especially suitable for low-pressure and ordinary environments.

Cast iron pipe: Good durability, suitable for the transformation of old urban pipe networks.

2. Drainage pipeline

Drainage pipelines are used to discharge urban rainwater and sewage to ensure the smooth flow of urban drainage systems. Drainage pipes are divided into rainwater pipes and sewage pipes. Rainwater pipes mainly discharge precipitation, while sewage pipes treat wastewater from residents' lives and industrial production.

Common materials

Concrete pipes: Suitable for large-diameter, low-pressure rainwater pipes.

PVC pipes: Suitable for sewage pipes in residential and commercial areas, with corrosion resistance and anti-aging characteristics.

HDPE pipes: High-density polyethylene pipes, with excellent anti-leakage and anti-corrosion properties, are widely used in municipal pipelines.

3. Gas pipelines

Gas pipelines are used to transport urban natural gas or liquefied gas to supply residents and industrial gas. Safety is the top priority of gas pipeline design, and it must have the ability to prevent leakage and explosion.

Common materials

Steel pipes: Traditional natural gas transmission pipelines, with high strength, suitable for high-pressure environments.

PE pipes: Suitable for low-pressure areas, with good corrosion resistance.

4. Heating pipes

Heating pipes are used to transport hot water or steam from heat sources to various buildings to ensure the heating needs of the city. Such pipes need to have good high temperature resistance.

Common materials

Steel pipes: used in high temperature, low temperature and high pressure environments, with good thermal conductivity.

Prefabricated insulation pipes: The inner layer is usually insulated with materials such as polyurethane or glass wool.

871.webp)

981.webp)

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)