1. Introduction: Why Choosing the Right Water Pipe System Matters

Whether you're planning a residential renovation, setting up a commercial plumbing network, or designing a large-scale municipal water line, choosing the right water pipe system is crucial for long-term performance and cost-efficiency. With so many types of water pipes available, it’s easy to get overwhelmed.

Among the most commonly used water pipe materials in the market are PVC (Polyvinyl Chloride), PPR (Polypropylene Random Copolymer), and HDPE (High-Density Polyethylene). Each offers unique advantages and is suited for different types of water supply systems, depending on temperature, pressure, budget, and installation method.

In this article, we’ll explore the key features, strengths, and drawbacks of PVC, PPR, and HDPE water pipe systems—and help you determine which one is the best fit for your project.

2. Overview of Each Pipe Material

PVC (Polyvinyl Chloride) Pipes

PVC water pipe systems are widely used in cold water delivery, drainage systems, and rainwater collection. Thanks to their affordability and easy installation, PVC pipes have become a go-to choice for many residential and commercial applications.

Advantages

Lightweight and easy to transport

Corrosion-resistant and chemically stable

Low cost and widely available

Simple installation using solvent cement

Disadvantages

Not suitable for hot water (can deform at temperatures above 60°C)

Brittle under impact or extreme cold

Requires care during cutting and fitting

Best for: Cold water systems, waste drainage, low-pressure installations

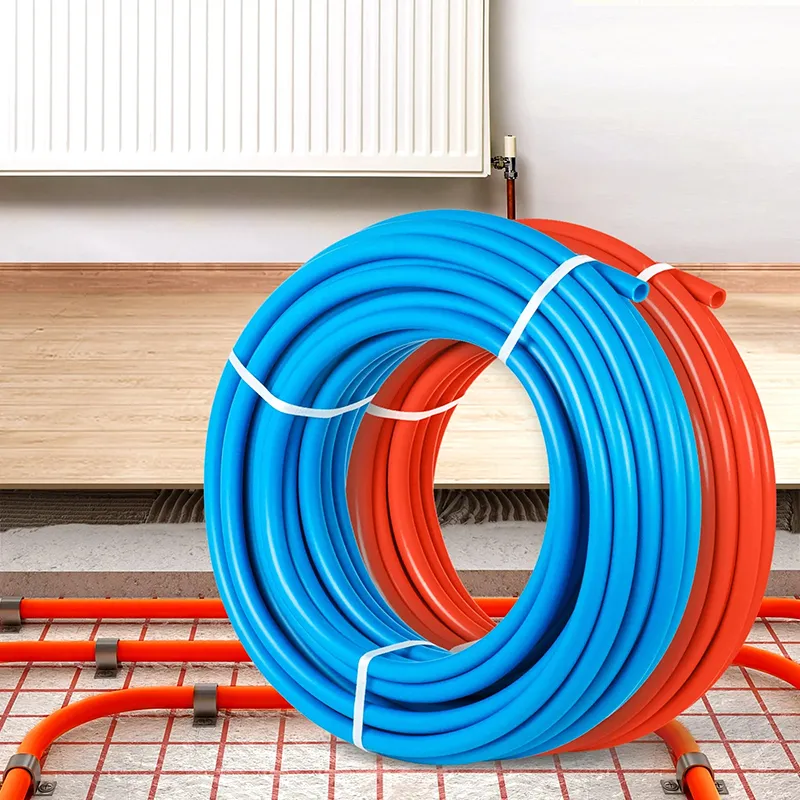

PPR (Polypropylene Random Copolymer) Pipes

PPR pipes are most often used in hot and cold drinking water systems, especially in domestic and commercial buildings. Their smooth inner surface resists scaling and bacterial growth, making them ideal for sanitary applications.

Advantages

Excellent thermal resistance (up to 95°C)

Food-grade material, safe for drinking water

Long service life (50+ years)

Minimal pressure loss due to smooth inner walls

Disadvantages

Higher cost compared to PVC

Requires heat fusion equipment and skilled installation

Best for: Residential hot/cold plumbing, central heating systems

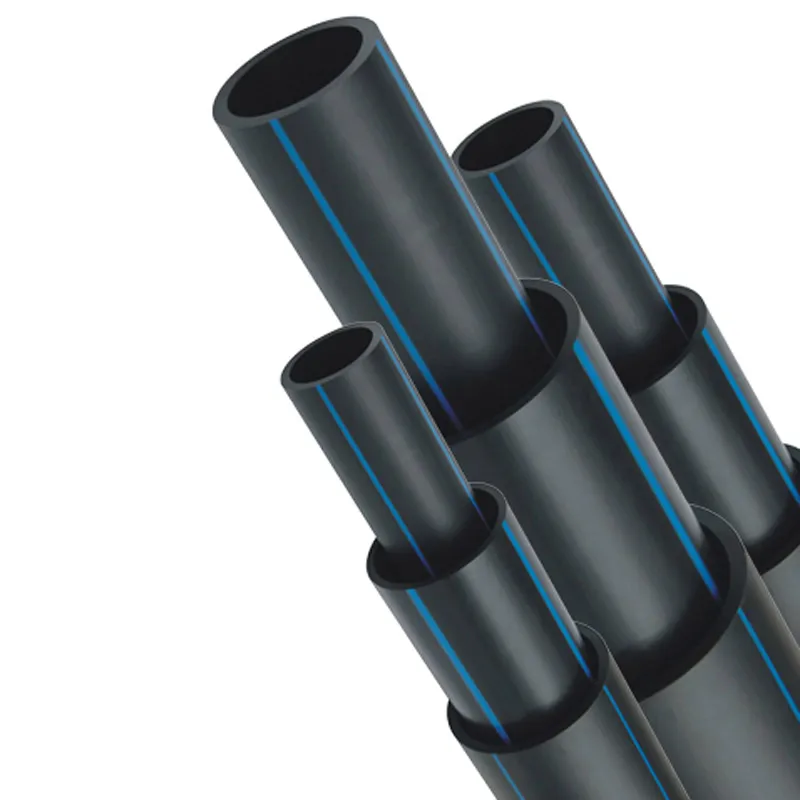

HDPE (High-Density Polyethylene) Pipes

HDPE water pipe systems are the preferred choice for long-distance water transport, buried pipelines, and irrigation networks. Their flexibility and high resistance to ground movement make them especially suited for underground or uneven terrains.

Advantages

Excellent impact and pressure resistance

Corrosion-free and UV-stable

Flexible for trenchless installation

Welded joints (butt fusion/electrofusion) ensure leak-free connections

Disadvantages

Requires special welding tools and trained technicians

Higher material and installation costs

Best for: Municipal water supply, irrigation systems, industrial water transport

3. Comparison Table: PVC vs PPR vs HDPE Pipes

| Feature | PVC Pipe | PPR Pipe | HDPE Pipe |

| Temperature Resistance | Low | Excellent | Good |

| Pressure Resistance | Moderate | High | High |

| Corrosion Resistance | High | High | High |

| Flexibility | Rigid | Rigid | Flexible |

| Cost | Lowest | Moderate | Higher |

| Installation Method | Glue or Joint | Heat Fusion | Butt Fusion or Electrofusion |

| Use Case | Cold Water, Drainage | Drinking Water, Heating | Municipal, Irrigation |

4. Which One Is Better for Your Project?

Choosing the right pipe depends on your specific needs and project conditions. Here's a quick recommendation based on common applications:

Home Plumbing

For hot and cold indoor plumbing, PPR offers excellent thermal resistance and hygienic safety. For budget-friendly cold water lines or drainage, PVC is a solid option.

Irrigation System

HDPE is ideal thanks to its flexibility, UV resistance, and leak-proof welding. It handles pressure and uneven terrain very well.

Underground Water Supply

HDPE is preferred due to its strength, fusion joints, and long service life under harsh underground conditions.

Budget Residential Use

PVC is economical, lightweight, and easy to install. It’s a great choice for non-pressurized or low-temperature systems.

All three materials—PVC, PPR, and HDPE—play a vital role in modern water pipe systems. Instead of asking which one is universally “better,” it’s more important to choose the one that suits your specific installation environment, temperature range, pressure requirements, and budget.

We manufacture and supply high-quality PVC, PPR, and HDPE pipe systems with full ranges of fittings, sizes, and customization options. Contact us today for technical support or a free quotation!

FAQ

Is HDPE pipe better than PVC for water?

It depends on the specific application. HDPE (High-Density Polyethylene) pipes offer superior flexibility, high impact resistance, and excellent chemical resistance, making them ideal for underground water supply systems, agricultural irrigation, and industrial water transfer. HDPE pipes are also suitable for high-pressure environments and can be installed using butt fusion or electrofusion techniques, creating strong, leak-free joints.

PVC (Polyvinyl Chloride) pipes, on the other hand, are more rigid and best suited for low-pressure cold water systems such as residential plumbing and drainage. PVC is lightweight, cost-effective, and easy to install, but it cannot handle high temperatures or significant ground movement.

Conclusion:

For high-pressure, underground, or flexible installations, HDPE is better.

For low-cost, cold water, above-ground systems, PVC is more economical.

What is the lifespan of PPR pipes?

PPR (Polypropylene Random Copolymer) pipes are known for their durability, especially in hot and cold water plumbing systems. Under proper installation and normal operating conditions, the average lifespan of PPR pipes can reach 50 years or more.

Their longevity is due to:

High resistance to heat and pressure

Excellent chemical and corrosion resistance

Smooth inner walls that prevent scaling and blockages

In residential or commercial applications where consistent pressure and temperature are managed, PPR is a highly reliable and safe material, especially for potable water and central heating systems.

Tip: Choose high-quality PPR pipes from trusted manufacturers and ensure proper heat fusion connections for maximum service life.

Can I use PVC pipe for hot water?

Generally, PVC pipes are not recommended for hot water applications. Standard PVC starts to soften at temperatures above 60°C (140°F) and may deform, lose pressure resistance, or even leak when exposed to continuous high temperatures.

If you're planning a hot water system, better alternatives include:

PPR pipes (withstand up to 95°C)

CPVC pipes (Chlorinated PVC, suitable for hot water up to 90°C)

PEX pipes (commonly used in modern plumbing for both hot and cold water)

Using PVC for hot water can compromise safety and cause long-term failure. If you're unsure which material to use, always consult with a professional installer or pipe supplier.

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)