History of PVC (Polyvinyl Chloride)

PVC, or Polyvinyl Chloride, is one of the oldest synthetic materials used in modern industries. Its journey from accidental discovery to widespread application is marked by several key developments. Below is an overview of the history of PVC:

1. Early Discoveries (19th Century)

1835 - First Observation: PVC was first discovered by French chemist Henri Victor Regnault when he noticed a white solid form inside a flask of vinyl chloride that was left exposed to sunlight.

1872 - Further Research: The German chemist Eugen Baumann also observed the formation of PVC as a solid material from the polymerization of vinyl chloride, but no practical application was found at the time.

2. First Patents and Research (Early 20th Century)

1913 - First PVC Patent: German inventor Fritz Klatte developed a method for synthesizing PVC using sunlight and a hydrogen chloride compound. He applied for a patent, though commercial uses for PVC were still limited because the material was brittle and difficult to work with.

1926 - Breakthrough in Flexibility: American scientist Waldo Semon, working for B.F. Goodrich, discovered a way to make PVC more flexible by adding plasticizers. This made it a more usable material for a variety of products, such as insulation for electrical wires.

3. World War II Era (1930s - 1940s)

Increased Demand: During World War II, PVC gained prominence as a substitute for rubber, which was in short supply. It was used for insulation, aircraft parts, and other wartime materials.

Post-War Expansion: After the war, PVC’s use expanded in the construction industry for pipes, flooring, and siding due to its durability, affordability, and ease of manufacturing.

4. Growth in Applications (1950s - 1970s)

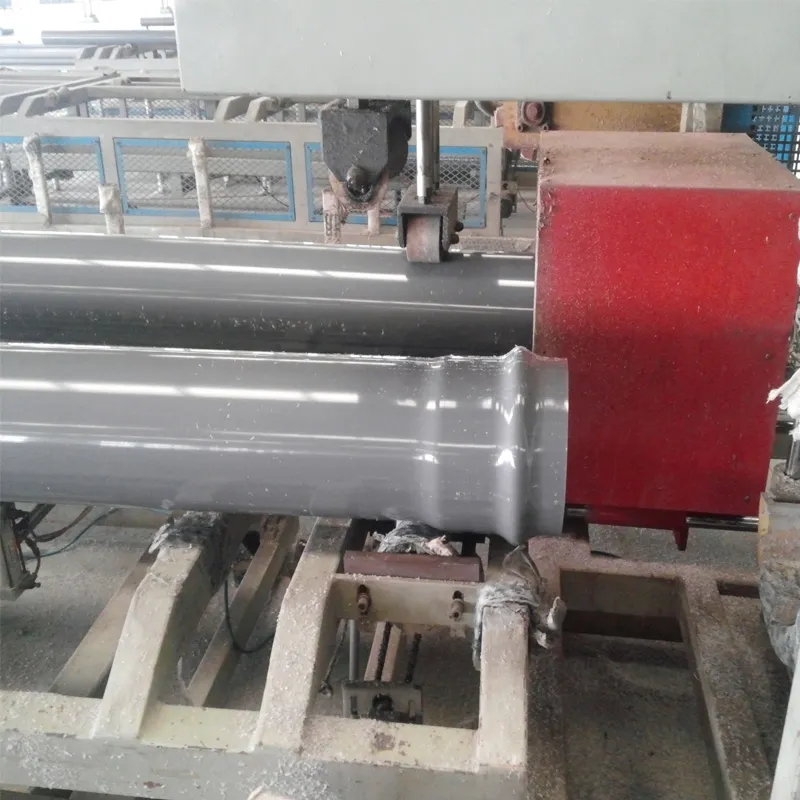

Widespread Use in Pipes: By the 1950s, PVC became the material of choice for water and sewage pipes due to its resistance to corrosion and chemical damage. It soon replaced traditional materials like cast iron and lead.

Other Applications: The versatility of PVC allowed it to be used in clothing, medical devices (such as IV bags and tubes), packaging, and consumer goods like records and toys.

5. Technological and Environmental Developments (1980s - Present)

Technological Advancements: Ongoing research led to improvements in PVC’s formulation, resulting in higher durability and reduced environmental impact. New stabilizers and additives were developed to address safety concerns.

Environmental Concerns: PVC faced criticism over its environmental impact, particularly regarding the release of dioxins during production and disposal. In response, recycling efforts and eco-friendly alternatives have been developed, although PVC remains widely used.

Recycling and Sustainability: Today, PVC recycling programs are more common, and there are ongoing efforts to improve its environmental footprint through more sustainable production processes.

6. Modern-Day Use

Global Dominance: PVC is one of the most widely produced plastics in the world. Its applications span construction (pipes, windows, flooring), healthcare (medical devices), packaging, and automotive industries.

Innovations: The development of high-performance and specialty PVC materials continues to drive its use in cutting-edge applications, including energy-efficient building materials and environmentally conscious products.

PVC Case Studies

1. PVC Piping in Municipal Water Systems

Location: United States

Overview: In many cities across the U.S., aging metal water pipes (typically made from materials like cast iron and copper) were corroding and causing water leakage, contamination, and significant maintenance costs. Municipalities began to replace these pipes with PVC, due to its non-corrosive nature and lower installation cost.

Outcome: Cities that transitioned to PVC piping reported a reduction in water loss, lower maintenance costs, and longer service life (up to 100 years in some cases). The switch also helped to prevent contamination of water from corroded pipes, improving overall water quality.

2. PVC Roofing in Sustainable Construction

Location: Germany

Overview: As part of a large sustainability initiative, a commercial complex in Germany was built using PVC membrane roofing. The decision was based on PVC’s durability, energy efficiency, and recyclability.

Outcome: The PVC roofing improved the energy efficiency of the building by reflecting heat and reducing cooling costs. It also contributed to a longer lifespan of the roof (estimated at 25+ years) compared to traditional roofing materials. The roof’s recyclability also aligned with the building's overall green certification goals.

3. PVC in the Medical Industry – IV Bags and Tubes

Location: Global

Overview: PVC has been used extensively in the medical industry, particularly for intravenous (IV) bags and tubing, due to its flexibility, safety, and ease of sterilization. However, concerns about plasticizers used in PVC products led to some controversy in the 1990s, prompting the medical industry to look for alternatives.

Outcome: After thorough studies, most PVC-based medical products were found to be safe for patient use. As a result, PVC remains a dominant material in medical applications, although innovations in plasticizer technologies have led to the development of alternatives to reduce potential risks. New formulations of flexible PVC continue to be a critical part of life-saving medical devices.

4. Vinyl Flooring in Commercial Spaces

Location: United Kingdom

Overview: A large commercial building in London opted for PVC (vinyl) flooring due to its affordability, easy maintenance, and durability. The company chose a high-performance PVC flooring product designed to withstand heavy foot traffic while providing sound insulation.

Outcome: After several years of use, the building managers reported that the PVC flooring maintained its appearance and function, requiring less upkeep than other types of flooring. Additionally, the PVC flooring’s acoustic properties helped reduce noise levels in the building, improving the work environment.

5. PVC Windows in Energy-Efficient Homes

Location: Scandinavia

Overview: In Scandinavia, energy efficiency is a top priority due to the region’s cold climate. A housing development project adopted PVC windows due to their excellent insulation properties, durability, and minimal maintenance requirements.

Outcome: The PVC windows helped reduce energy consumption for heating by providing superior thermal insulation. Homeowners reported significant reductions in their energy bills, and the windows' long-lasting material meant they did not need frequent replacement, adding to the overall cost-effectiveness of the choice.

6. Wastewater Management Using PVC Pipes

Location: India

Overview: In rural areas of India, where sanitation infrastructure is often lacking, a project aimed to improve wastewater management by installing PVC pipes. The lightweight, durable, and easy-to-install properties of PVC made it the ideal choice for laying underground sewage systems in these remote locations.

Outcome: The introduction of PVC pipes drastically improved sanitation, reduced wastewater leakage, and helped prevent waterborne diseases in the area. The cost savings associated with PVC allowed the project to cover a larger area, benefiting more communities within the same budget.

These case studies highlight the versatility and durability of PVC across various industries, ranging from infrastructure and healthcare to construction and sustainability efforts.

629.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)