600411.jpg)

In the severe winter, the water will freeze, and the volume from water to ice will increase. If the cold-proof measures for the PE water supply pipe are not done well, the pipe will likely be cracked, and the damage will be immeasurable. Therefore, it is necessary to think about it.

Ways to prevent PE water pipe from freezing.

1. If it is partially shallow buried, part of the overburden can be appropriately raised, which can be designed by the general plan or landscape technology professional harmonious plan;

2. Whether the PE water supply pipe is used for waste heat recovery and upgrading the heat tracing pipe (will harm the water temperature)

The function of the heat tracing pipe: ① Prevent the viscosity of the liquid in the pipe from increasing at low temperature, increase the pressure drop in the pipe, increase the power consumption, and play a role in energy saving

②Prevent the gas in the pipe from condensing with liquid. Under different working conditions, there are requirements for the liquid in the gas sent by the pipe. The heating wire can be avoided and play a safety role.

③Prevent pipeline blockage caused by the solidification of piped liquid or slurry, and serious pipeline abandonment, which plays the role of equipment maintenance

④Anti-freezing and anti-condensation

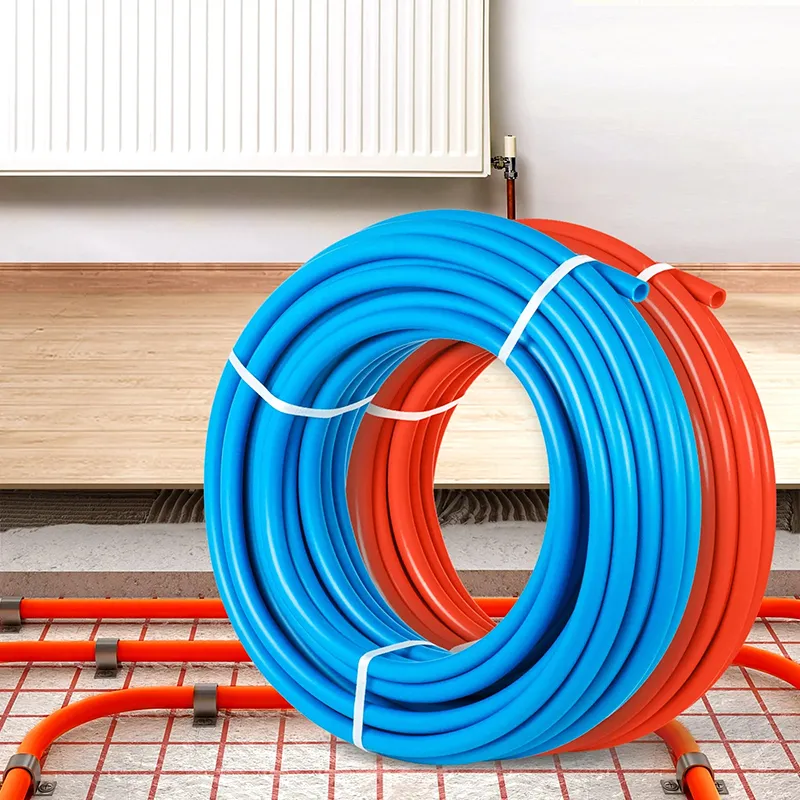

3. Electric heat tracing

There are both indoor and outdoor water pipes. When the temperature is low in winter, freezing will occur, especially since the pipes exposed to the air outside are more likely to freeze and block, and even cause the water pipes to freeze and crack, affecting the normal life of residents. Water is used, so in cold winter areas, it is very important to take measures to prevent the freezing of water pipes in winter.

As a new type of pipeline insulation method, electric heat tracing insulation is very suitable for antifreeze insulation of water pipes. When the electric heating cable is energized and heated, it is only necessary to maintain the temperature of the pipeline above 0°C to prevent the water pipeline from freezing and meet the requirements of anti-freezing and heat preservation.

The indoor tap water pipeline belongs to the common area, and the low-temperature protection self-limiting electric heating cable can be selected. The working temperature of the electric heating cable is 65 degrees, which can meet the requirements of antifreeze for water pipes. It is mainly used in places without explosion-proof and anti-corrosion requirements at low temperatures and with little change in ambient humidity. It is suitable for indoor water pipe and water tank insulation.

For outdoor water pipes, considering the waterproof problem, it is more reliable to choose the explosion-proof enhanced self-limiting electric heating cable. The electric heating cable is added with a layer of metal shielding layer and polyolefin outer sheath. The metal braided layer conducts heat and dissipates heat quickly. The polyolefin outer sheath has good moisture-proof performance and plays the role of safety and grounding protection. It is suitable for antifreeze and heat preservation of outdoor water pipes.

4. Is the PE water supply pipe available for underground structures, such as garages, corridors, trench excavation, etc

The basic burial depth and pipeline design of PE water supply pipes in severe cold areas require comprehensive consideration of various factors, and flexible use of waste heat recovery and building temperature. Only in this way can the water supply and drainage pipelines be properly used in winter.

Construction precautions for PE pipe insulation

1. If it is applied to indoor water supply in residential areas, urban water supply pipelines, marine aquaculture, etc. The insulation of the PE pipe and equipment should be stopped before the anti-corrosion and water pressure tests are qualified. If the insulation layer needs to be made first, the joints and welds of the pipes should be reserved, and the joints should be insulated after the water pressure test is qualified;

2. If the ceiling of the building and the pipeline in the tube well need to be insulated, the civil engineering should be closed after the anti-corrosion pressure test is qualified, and the insulation inspection is completed, and the construction of the reverse process is prohibited. Before insulation, the debris in the trench pipe well needs to be cleaned up, and the debris left in the construction process should be cleared at any time to ensure the dredging of the trench.

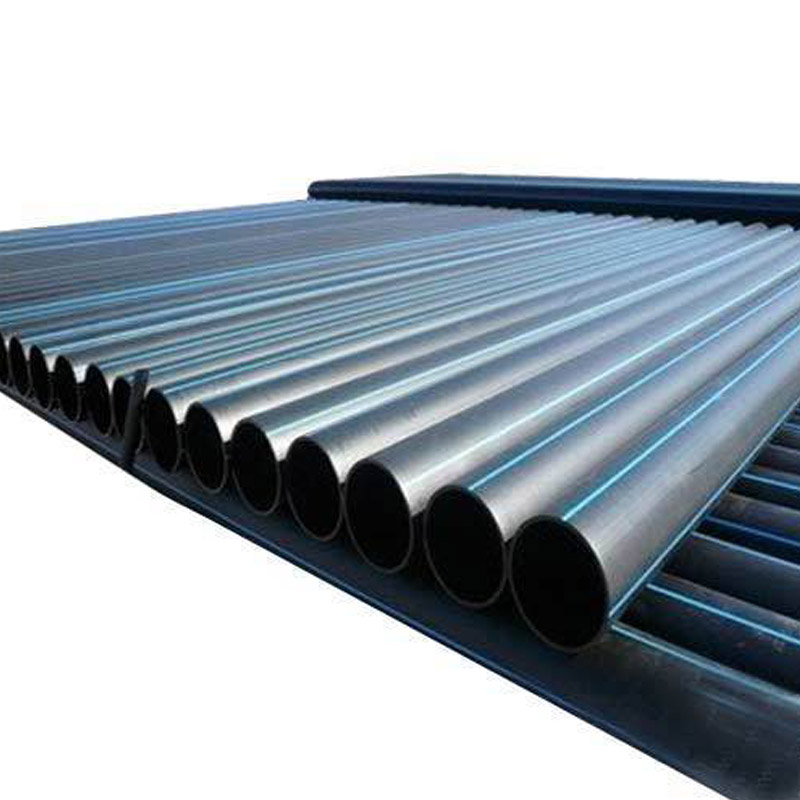

Precautions when storing PE pipes

PE water supply pipes are widely used. To better meet different needs, PE water supply pipes have various pipe diameters. When storing, the water supply pipes with large diameters should be placed at the bottom and arranged one after another. The outside of the PE water supply pipe is relatively smooth. To better prevent dragging during loading and unloading, it should be fixed with a rope or the like. Small-diameter pipes or straight pipes can be loaded, unloaded, and transported with bare hands. Care should be taken to handle them carefully to prevent cracks. The storage place should be kept clean and hygienic. PE water supply pipes that need to be stored for a long time should be placed indoors or covered with canvas to prevent long-term direct sunlight. For buried pipes, trenches should be dug in advance, and sharp and hard objects such as stones in the trenches should be removed to prevent pipes from being squeezed and cracked. Heavy objects should not be deposited on the top of PE pipes to prevent destructive extrusion of pipes. . Store it well to ensure that it can fully play its role in the application process.

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)