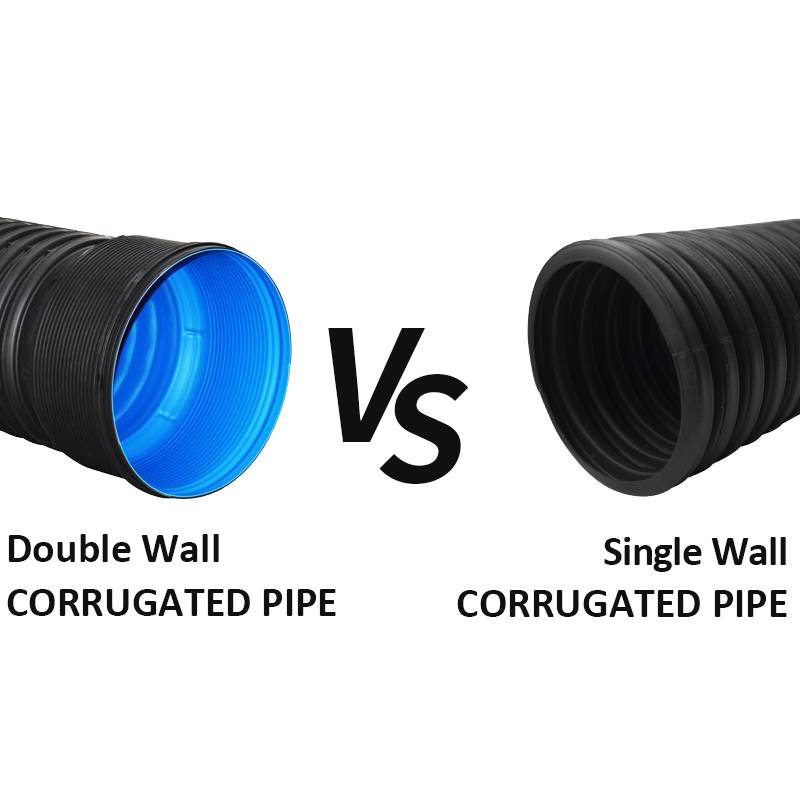

1. Application between Dual wall vs single wall corrugated pipe

Plastic double-wall corrugated pipes can be widely used in drainage and water permeation under heavy loads such as highways, slopes, golf courses; municipal sewage; communication, power supply cable casings, and other occasions.

Single-wall corrugated pipes can be widely used in golf courses, sports fields, and other light-load conditions, such as drainage and water penetration; interior decoration wire casings; automobile wire casings; prestressed anchor cable casings; air conditioner drainage pipes, etc.

2. Performance between Dual wall vs single wall corrugated pipe

Under the same strength and rigidity requirements, the use of double-wall corrugated pipes can save 30%-50% of materials compared with ordinary plastic pipes, with the better technical economy, and convenient transportation and installation, which reduces the labor intensity of construction personnel, and also reduces the cost of The total investment of the project, but the curvature is small.

3. In terms of weight and ring stiffness between Dual wall vs single wall corrugated pipe

HDPE double-wall corrugated pipe is much heavier and taller than single-walled corrugated pipe, and double-walled corrugated pipe is much more rigid than a single-walled ring.

Cutting Requirements for HDPE Double Wall Corrugated Pipe

1. It should not be cut by mechanical or plasma methods;

2. The double-wall corrugated pipe can be cut by mechanical or manual methods;

3. Special grinding wheel should be used when cutting or grinding with a grinding wheel;

4. Carbon steel mining pipes and galvanized steel pipes should be cut with a hacksaw or mechanical methods;

5. The quality of pipe cuts should meet the following requirements:

(1) The incision surface of the double-wall corrugated pipe should be smooth, free of cracks, heavy skins, burrs, bumps, necks, slag, oxides, iron filings, etc.;

(2) The inclination deviation of the end face of the incision shall not be greater than 1% of the outer diameter of the pipe, and shall not exceed 3mm; the concave and convex error shall not exceed 1mm.

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)