Understanding HDPE Double-Walled Corrugated Pipes

Composition and Structure

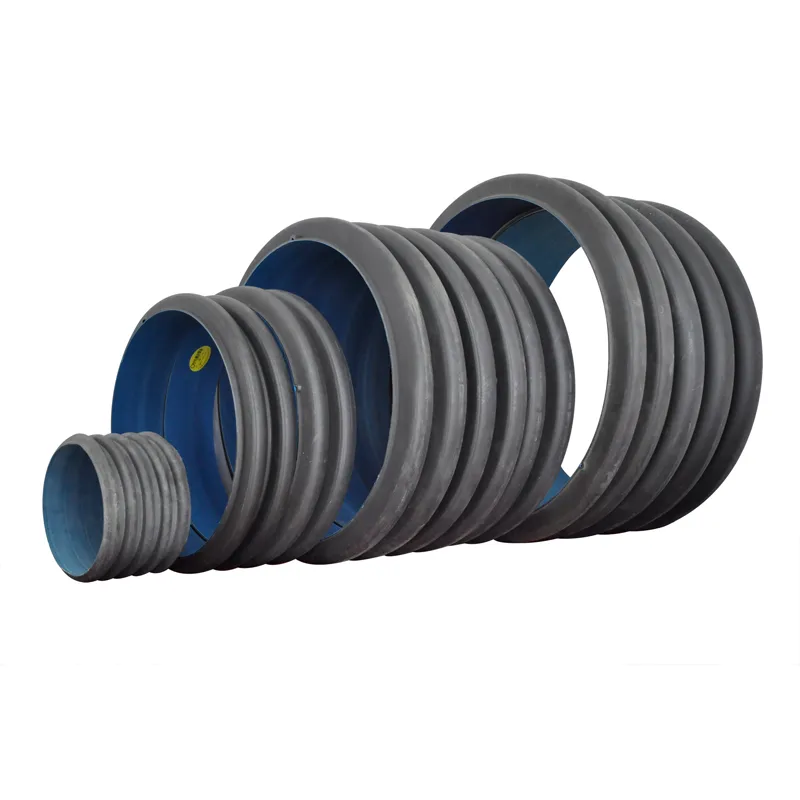

HDPE double-walled corrugated pipes consist of two layers:

1. Outer Corrugated Wall: Provides structural strength and resistance to external loads.

2. Inner Smooth Wall: Ensures smooth water flow, reducing friction and preventing clogging.

Key Features

1. High Strength-to-Weight Ratio: Despite being lightweight, these pipes offer exceptional strength, making them easy to handle and install without compromising performance.

2. Chemical Resistance: HDPE material is resistant to a wide range of chemicals, ensuring the pipes' longevity in various environments.

3. Flexibility: The flexibility of HDPE allows these pipes to withstand ground movements and settlements without cracking.

Advantages of HDPE Double-Walled Corrugated Pipes

1. Durability

HDPE pipes are known for their long lifespan, often exceeding 50 years. They resist corrosion, abrasion, and the effects of harsh environmental conditions, making them ideal for long-term drainage solutions.

2. Cost-Effectiveness

The lightweight nature of HDPE pipes reduces transportation and installation costs. Additionally, their durability means fewer replacements and repairs, leading to lower long-term maintenance costs.

3. Environmental Benefits

HDPE is a recyclable material, contributing to environmental sustainability. The manufacturing process of HDPE pipes also has a lower carbon footprint compared to traditional materials like concrete or metal.

4. Leak-Free Joints

HDPE double-walled corrugated pipes are often joined using advanced welding techniques, creating a seamless, leak-free system. This is crucial for preventing water loss and maintaining the integrity of the drainage system.

Applications of HDPE Double-Walled Corrugated Pipes

1. Municipal Drainage Systems

HDPE double-walled corrugated pipes are extensively used in municipal drainage systems. They efficiently manage stormwater and sewage, preventing flooding and ensuring the smooth operation of urban infrastructure.

2. Agricultural Drainage

In agriculture, these pipes are used for field drainage to prevent waterlogging and ensure optimal soil conditions for crop growth. Their flexibility allows them to be laid in fields with varying terrain.

3. Industrial Drainage

Industries use HDPE double-walled corrugated pipes for the drainage of process water and wastewater. Their chemical resistance ensures they can handle a wide range of industrial effluents without degrading.

4. Road and Highway Drainage

These pipes are ideal for road and highway drainage systems, efficiently channeling water away from road surfaces and preventing damage caused by water accumulation.

Installation of HDPE Double-Walled Corrugated Pipes

Preparation

1. Site Assessment: Conduct a thorough assessment of the installation site, including soil testing and water flow analysis.

2. Pipe Selection: Choose the appropriate pipe diameter and pressure rating based on the specific drainage requirements.

Installation Steps

1. Trenching: Dig trenches according to the planned layout. Ensure the trenches are free from sharp objects and provide adequate support for the pipes.

2. Bedding: Lay a bedding layer of sand or gravel to provide a stable base for the pipes.

3. Pipe Laying: Place the pipes in the trenches, ensuring proper alignment and gradient for optimal water flow.

4. Joining the Pipes: Use appropriate joining methods such as thermal welding or rubber gaskets to ensure a leak-free connection.

5. Backfilling: Carefully backfill the trenches, ensuring there are no sharp objects that could damage the pipes.

Testing

After installation, conduct pressure tests to ensure the system is leak-free and functioning correctly. This step is crucial to identify any potential issues before the system is put into operation.

Maintenance of HDPE Double-Walled Corrugated Pipes

Regular Inspections

1. Visual Inspections: Regularly inspect the pipes for any visible signs of damage or wear.

2. Leak Detection: Use leak detection equipment to identify any hidden leaks in the system.

Cleaning

1. Flushing: Periodically flush the system to remove any sediment or debris that may have accumulated.

2. Chemical Cleaning: In case of severe buildup, use approved chemical cleaners to ensure the pipes remain clean and functional.

Repairs

1. Minor Repairs: For small leaks or cracks, use appropriate repair kits designed for HDPE pipes.

2. Major Repairs: In case of significant damage, replace the affected section of the pipe. Ensure proper welding to maintain a leak-free system.

Innovations and Future Trends

Smart Drainage Systems

The integration of sensors and monitoring systems in HDPE pipes is an emerging trend. These smart systems can provide real-time data on water flow, pressure, and potential blockages, enabling proactive maintenance and management.

Improved Manufacturing Techniques

Advances in manufacturing techniques are leading to the production of HDPE pipes with enhanced strength, flexibility, and durability. These improvements will further solidify HDPE's position as the material of choice for drainage systems.

Environmental Considerations

With increasing emphasis on sustainability, there is a growing focus on developing HDPE pipes with lower environmental impact. This includes the use of recycled materials and more energy-efficient manufacturing processes.

HDPE drainage double-walled corrugated pipes represent a significant advancement in drainage technology. Their combination of durability, cost-effectiveness, and environmental benefits makes them an ideal choice for a wide range of applications, from municipal and agricultural drainage to industrial and road drainage systems.

As technology continues to evolve, the capabilities and applications of HDPE pipes will expand, offering even greater efficiency and reliability in drainage solutions. For those involved in designing, installing, and maintaining drainage systems, understanding the benefits and best practices associated with HDPE double-walled corrugated pipes is essential for achieving optimal results.

For more information on HDPE drainage double-walled corrugated pipes and to explore our wide range of products, visit our website or contact our experts today. We are committed to providing you with the best solutions for all your drainage needs.

981.webp)

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)