Pressure Rating

To begin with, it's important to understand that the pressure rating of a gas pipe refers to the maximum operating pressure at which the pipe can safely operate. This pressure is determined based on the strength of the pipe material and the pipe's size and wall thickness.

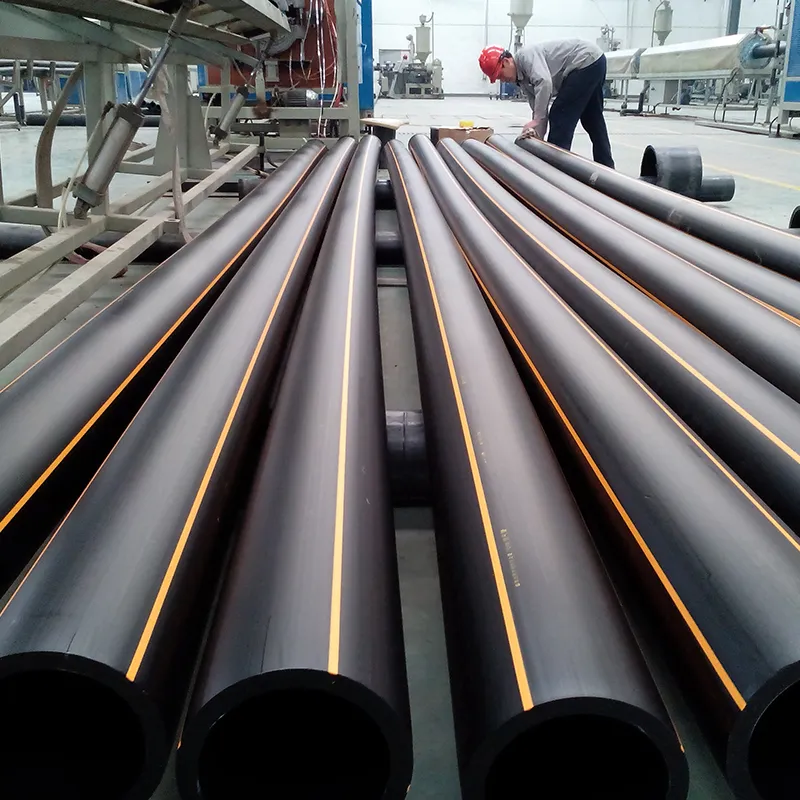

HDPE pipes have a high strength-to-density ratio, which makes them ideal for use in high-pressure gas pipelines. They are also resistant to corrosion, which makes them a long-lasting and reliable choice for gas transportation.

The pressure rating of HDPE gas pipes is typically expressed in pounds per square inch (psi). The minimum required strength of the pipe is determined by the maximum operating pressure (MOP) of the pipeline, as well as the design factor (DF) and the safety factor (SF). The MOP is determined by the maximum pressure that the pipeline will experience during normal operation, while the DF and SF are used to account for factors such as fluctuations in pressure and temperature.

The MOP of HDPE gas pipe

To determine the MOP of an HDPE gas pipe, the following formula can be used:

MOP = (2 * DF * SF * Y) / (D - 2 * C)

Where:

DF is the design factor (typically 0.5 for gas pipelines)

SF is the safety factor (typically 1.5 for gas pipelines)

Y is the yield strength of the pipe material (in psi)

D is the outside diameter of the pipe (in inches)

C is the minimum wall thickness of the pipe (in inches)

The yield strength of HDPE pipe is typically around 3,000 psi, although this can vary depending on the specific grade of HDPE used.

It's important to note that the MOP of an HDPE gas pipe should not be exceeded, as this can cause the pipe to fail and potentially result in a gas leak. It's also important to ensure that the pipeline is properly installed and maintained to ensure its continued safe operation. You can ask Haili members to the fresh new pressure rating and MOP of different kind of HDPE gas pipe, to choose the most cost efficent pipe for you.

The real data of Haili gas pipe

According to data from the Plastics Pipe Institute, the pressure ratings for HDPE gas pipes are as follows:

For pipes with a diameter of 2 inches or less, the maximum operating pressure (MOP) is 125 psi

For pipes with a diameter of 2.5 inches or more, the MOP is 100 psi

These values are based on a design factor (DF) of 0.5 and a safety factor (SF) of 1.5, as well as a yield strength of the HDPE material of 3,000 psi.

It's worth noting that these pressure ratings are for pipes made from a specific grade of HDPE, known as PE4710. Haili use PE4710 as our main material of HDPE gas pipe. This grade of HDPE has a higher strength and lower density than other grades, which allows it to withstand higher pressures.

In addition to the pressure rating, it's also important to consider other factors when selecting an HDPE gas pipe. These may include the pipe's ability to resist corrosion, its flexibility and ease of installation, and its overall cost.

Conclusion

HDPE gas pipes are a reliable and durable choice for the transportation of natural gas. The pressure rating of these pipes is determined by the maximum operating pressure (MOP), which is calculated based on the strength of the pipe material, the pipe's size and wall thickness, and various design and safety factors. It's important to ensure that the MOP of an HDPE gas pipe is not exceeded in order to prevent failure and potential gas leaks.

Overall, HDPE gas pipes are a strong and reliable choice for the transportation of natural gas, with a pressure rating that can safely handle the demands of most gas pipeline systems. As always, it's important to properly design, install, and maintain the pipeline to ensure its continued safe operation.

You can ask members of the Haili team about the latest pressure ratings and maximum operating pressures (MOPs) of different types of HDPE gas pipes to determine the most cost-efficient option for your needs. They can provide you with detailed information about the strengths and capabilities of different grades of HDPE gas pipes, as well as recommendations for the best type of pipe for your specific application

258.webp)

971.webp)

580.webp)

655.webp)

294.webp)

476.webp)

420.webp)

146.webp)