How to remove PE mining sewer pipe in mine

Due to the extreme environment in contemporary mine work, the usual pipes cannot be used for the water delivery work in the mine, while the PE water supply pipe has become popular due to its excellent characteristics, and the work in the mine is often due to common failures or changes. The route requires everyone to disassemble and assemble the pipe. Only the proper disassembly and assembly process can ensure that the pipe is not prone to problems during disassembly and assembly.

1. When the PE water supply pipe maintenance staff needs to dismantle the pipeline, they must clearly submit a written application. After signing and willing, the project can be constructed within the required time.

2. During the disassembly and assembly of the pipeline, a person in charge of ventilation must be on the scene and jointly command. There is no person in charge of ventilation on the spot, and construction is prohibited.

3. Special tools such as wrenches on the disassembly and assembly lineman's belt must be made of copper to avoid collision with other iron tools during the disassembly and assembly period, resulting in collision sparks; for each construction site, prepare at least 2 fire extinguishers in advance.

4. Every time the pipeline is disassembled and assembled, a full-time tile inspector must be assigned on the spot, and a dry tile detector, gas and carbon monoxide portable instrument must be brought to ensure that the gas concentration value on the spot can be checked anytime, anywhere.

5. Before starting the disassembly and installation of the PE water supply pipe, the tile inspector first checks the gas concentration value in the working area, and after confirming the safety, the project can be constructed.

6. During the whole process of transporting and disassembling the pipeline, it should be handled with care, and the situation of touching hands and feet is prohibited.

7. When the gas concentration in the disassembly pipeline is less than 0.5%, the on-site tile inspector shall report to the production scheduling of the ventilation area. After receiving the report, the on-duty cadre in the ventilation area shall notify the drainage pump driver to stop the pump, and after the drainage pump stops running , you can start to disassemble and assemble the pipeline.

8. During the mid-term of the disassembly and installation of the pipeline, the tile inspector will check the gas concentration in the pipeline and the construction site from time to time. If the gas concentration in the pipeline is found to exceed 0.5% or the gas at the construction site exceeds the limit, the project construction will be terminated immediately. , After taking effective countermeasures, the gas concentration in the pipeline is reduced to below 0.5%, and the construction site gas does not exceed the limit, and then the project can be re-constructed.

9. When the disassembly and assembly of the PE water supply pipe is completed, the ventilation cadre on the spot shall report to the production scheduling in the ventilation area. After receiving the report, the on-duty cadre in the ventilation area shall notify the drainage chamber driver to repair the operation of the drainage pump.

Repair method of PE pipe

PE pipe often encounters stumbling and stumbling during the application process, so its damage is unavoidable. In order to better prevent disassembly and replacement from interfering with normal applications and increase costs, the company chooses repairs to replace new products in most cases.

When the surface damage of the pe pipe shows the broken pipe wall or the hole within 0.1m in length, the scraper should completely remove the broken pipe wall or hole, and clean it with cyclohexanone within 0.05m around the removed position, and the brush has good wear resistance. Then remove the arc-shaped plate with twice the damaged area from the corresponding position of the same pipe, apply the adhesive to the inner cavity and stick it on the damaged position, and bind it with lead wire to fix it. If there are ribs on the surface of the pipe, remove the ribs within 0.05m of the periphery of the damaged position, scrape them off without rib marks, and use the same method to save.

When the surface of the PE pipe has some or small gaps or holes within 0.02m, the water in the pipe can be removed first, and the damaged position can be cleaned with cotton yarn, and then brush the base surface with cyclohexanone. A good plastic adhesive is used; and a board of similar size is removed from the corresponding position of the unused pipe, bonded, wrapped with geotextile to fix it, and the soil can be restored after 24 hours of drying.

The repair method of PE pipes is not single, and corresponding adjustments should be carried out according to the details of the surface damage. When carrying out this work, it is necessary to seek the assistance of professionals and carry it out cautiously to prevent secondary injuries.

How to passivate PE pipe

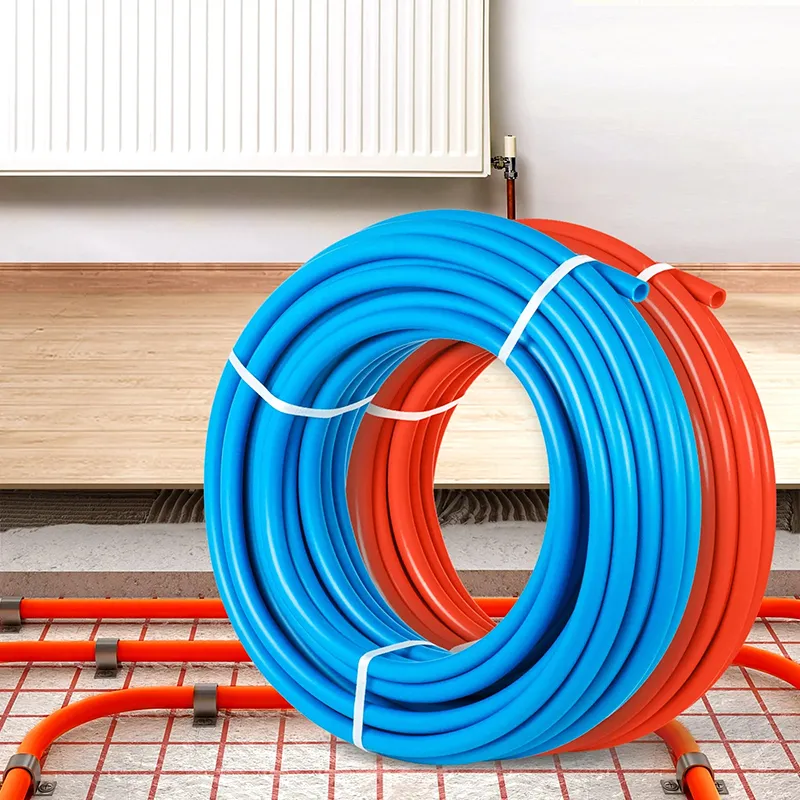

As the mainstream water pipes used in industrial production, PE pipes are generally encountered in extreme operating environments, which requires us to improve the quality and resistance of pipes as much as possible according to effective methods. Among them, passivation treatment for water pipes is often used. to a class of squares to try.

1. Preparation

The corresponding acid solution is prepared according to the required amount, and the solution is prepared by nitric acid + hydrofluoric acid; the acid-resistant passivation treatment tank and its steel brush are prepared in advance.

2. Chemical pickling of PE pipes

Using the soaking method in the tank, soak the steel pipe in the pickling solution and rotate it continuously to achieve the actual effect of sufficient work; if it encounters strong stains, it can be wiped off with a steel brush.

3. Rinse

After pickling, the gas drainage pipe is cleaned by alternating hot and cold water, and the cleaning time is not less than 20 minutes.

4, PE pipe passivation treatment

Apply the passivation agent to the workpiece that has already been pickled and stand still for a while, so that the passivation film is completely absorbed on the surface.

5. Dry

Place the gas extraction pipe in pure air for natural passivation.

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)