Advantages of PE pipeline hot-melt welding technology

Hot-melt welding technology is an advanced pipeline connection method. It uses a professional hot-melt welding machine to heat both ends of the pipeline to a molten state, and then quickly docks them to achieve a tight connection through the heat and pressure of the pipeline itself. This process has the following significant advantages:

1. High sealing and safety: The strength of the connection formed by hot-melt welding exceeds the body strength of the pipe and fittings, ensuring the sealing and safety of the pipeline.

2. Simple operation and short construction period: The operation steps of the hot melt welding process are relatively simple, and the construction period is short, which can greatly shorten the project period.

3. Low cost: Compared with other connection methods, the hot melt welding process does not require the use of toxic and harmful solvents, which reduces the construction cost.

4. Strong environmental protection: No toxic and harmful waste is produced during the hot melt welding process, reducing the risk of environmental pollution.

Innovation of PE pipeline hot melt welding technology

Driven by environmental protection policies, PE pipeline hot melt welding technology continues to innovate to meet market demand and environmental protection requirements.

1. Innovation of hot melt butt joint and hot melt socket connection

· With the continuous advancement of technology, hot melt butt joint and socket connection are more and more widely used in PE pipeline systems. By optimizing the welding parameters and processes, the strength and stability of the connection are improved.

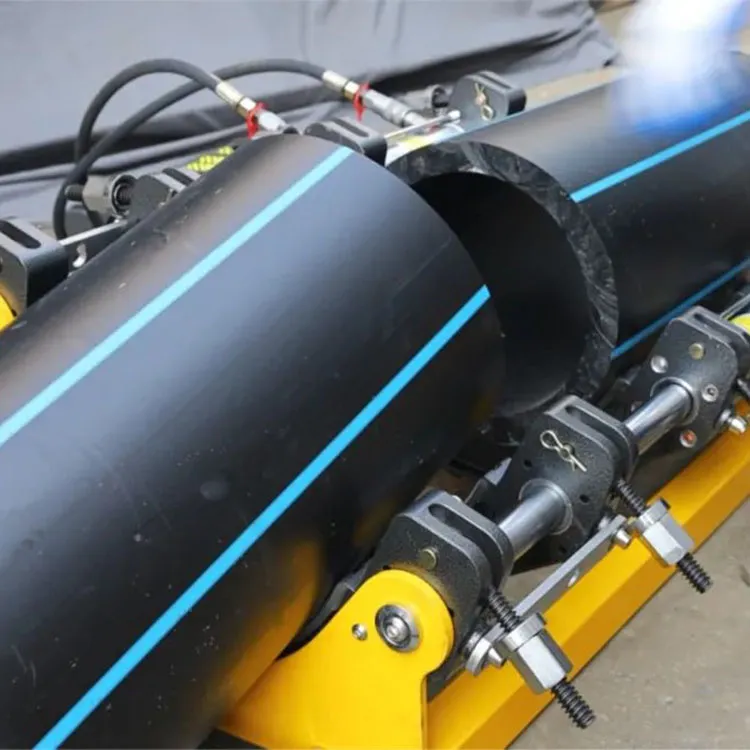

· Hot melt butt joint: suitable for pipes and fittings with relatively large diameters, it is more economical and easier to manufacture than socket connection. Cut off the oxidized surface layer before welding, the welding pressure can be controlled, and the quality is easier to guarantee. Hot-melt socket connection: suitable for pipes and fittings with relatively small diameters, because the pipes and fittings with small diameters have thinner walls and smaller cross-sections, and it is not easy to ensure the quality by butt connection.

2. Innovation of automated welding technology With the maturity and popularization of automation technology, PE pipe hot-melt welding technology is also gradually being automated. Automated welding equipment can significantly improve welding efficiency, reduce costs, and improve welding quality. In the future, with the popularization of automated welding equipment, PE pipe welding will become simpler, faster and more reliable.

3. Innovation in the combination of hardware and software Through technical means such as sensors, data acquisition and analysis, the temperature, pressure and other parameters in the welding process can be monitored in real time, and the welding quality can be accurately controlled and adjusted. At the same time, combined with artificial intelligence technology, welding data can be deeply learned and analyzed to improve the efficiency and quality of welding.

4. Innovation of new welding technology With the enhancement of environmental awareness, new welding technologies that replace traditional welding methods are gradually emerging. For example, hot and cold fusion technology, ultrasonic welding, etc. These technologies not only reduce energy consumption and pollution in the welding process, but also improve welding quality and stability.

Development trend of PE pipeline hot melt welding technology

Driven by environmental protection policies, the development of PE pipeline hot melt welding technology will show the following trends:

1. Wide application of automated welding technology

Automated welding technology will gradually become the mainstream of PE pipeline welding. By introducing automated welding equipment, welding efficiency can be significantly improved, costs can be reduced, and welding quality can be improved. At the same time, automated welding can also reduce errors in manual operation and improve welding accuracy and stability.

2. Deepening of the combination of hardware and software

In the future, PE pipeline hot melt welding will pay more attention to the combination of hardware and software. Through technical means such as sensors, data acquisition and analysis, various parameters in the welding process can be monitored in real time, and the welding quality can be accurately controlled and adjusted. At the same time, combined with artificial intelligence technology, welding data can be deeply learned and analyzed to provide data support for the optimization of welding process.

3. Promotion of new welding technology

With the enhancement of environmental awareness, new welding technologies will gradually replace traditional welding methods. For example, hot and cold fusion technology, ultrasonic welding, etc. These new welding technologies not only have higher environmental performance, but also can improve welding quality and stability. In the future, these technologies will be widely used in PE pipeline welding.

4. Introduction of intelligent management and maintenance

With the development of Internet of Things technology, PE pipe hot-melt welding will usher in an era of intelligent management and maintenance. Through sensors and Internet of Things technology, the operation status, temperature, pressure and other information of the pipeline can be monitored in real time, and remote monitoring and early warning can be carried out. This will greatly improve the safety and reliability of the pipeline and reduce maintenance costs and risks.

135835.webp)

981.webp)

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)