How to clean PE water pipe

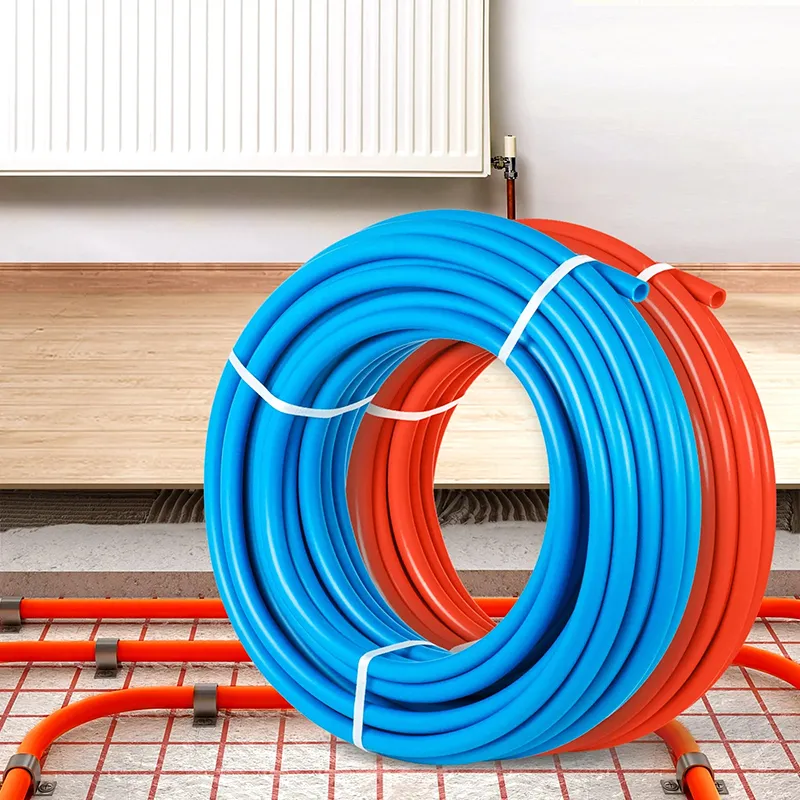

Polyethylene PE pipes are widely used in engineering building water supply, engineering building drainage, buried drainage pipes, engineering building heating, gas transmission pipes, electrical and telecommunication maintenance casings, industrial pipes, agricultural pipes because of their unique advantages. tube etc. It is mainly used in industries such as urban water supply, urban gas supply and agricultural irrigation.

The PE pipeline has been used for a long time, and it is likely to grow bacteria, stains, etc., which will cause corresponding interference to the water body. And tap water is indispensable in everyone's daily life, and hygiene and safety are very important. If there is interference such as germ stains in the PE pipe, the clean tap water will also suffer secondary environmental pollution, which will endanger everyone's physical and mental health.

1. Usually in a humid and cold environment, germs are very easy to grow, and an environment with sun is very easy to produce algae. We can add fungicides to the circulating system to remove germs and algae in the circulating water and keep the water body clean.

2. When the pipeline is draining, if there is a lot of residue in the water, it is very easy for biological sludge to adhere to the inner wall of the pipeline, which will increase over time, which will interfere with the runoff of the pipeline and even cause blockage. We can add a stripper to remove the slime according to the circulation system.

3. There may be floating iron, stains, oil stains and other residues in the pipeline system. We can add detergents, dispersants, etc. to disperse and discharge these substances to prevent residues on the pipe wall and maintain the cleanliness of the pipe wall. Sanitation.

4. In order to play a better role in corrosion resistance, we can also invest in pre-filming agents, which can produce a high-density polymeric polymer protective film on the inner wall of the pipeline, so that when the pipeline discharges waste water, there is no need to worry about the pipeline being corroded and interference characteristics.

5. When the pipeline is used for a long time, it is very easy to cause stains, interfere with the water body, and also interfere with the water flow. Therefore, we can add corrosion inhibitors and scale inhibitors to avoid the crystals and deposition of calcium and magnesium ions, thereby preventing stains caused.

PE pipe acceptance criteria

Among the rubber products, the wear resistance of PE pipe ranks the highest among plastics. Even so, in the case of use, it is also subject to engineering acceptance. Below, we will briefly understand the specifications that should be met for PE pipe engineering acceptance:

1. The products produced by reliable PE pipe manufacturers will be equipped with factory inspection reports and product qualification certificates. When the PE pipe is accepted by everyone, it is necessary to check whether there are these items.

2. In the case of project acceptance, it is also necessary to check the length of the PE pipe. The length of the PE pipe is uniform and the same, and the deviation is not large, which means that the standard is met. If the air outlet is found on the PE pipe, it is not suitable.

3. The PE pipe must be checked for the appearance of the PE pipe for project acceptance. At this moment, everyone must be careful about the inner and outer layers of the PE pipe to see if the surface of the PE pipe has defects and whether it is clean and tidy. If there are uneven colors, grooves, etc. on the PE pipe, it is not good.

Matters needing attention in PE pipe construction

1. Pipe scratches

Its raw material is soft and vulnerable to scratches, so it is necessary to prevent and prevent objects from touching during transportation. In particular, pay more attention when transporting and under the jurisdiction of the construction site. Due to the complicated terrain of the construction site, there are often iron nails and bricks and other protective objects on the home wall, which are very easy to scratch the PE.

2. Pipe stack

Pipes and pipe fittings should be covered with outer covers when they are temporarily stacked at the construction site to prevent the sun and precipitation, and should not come into contact with chemical substances such as oil, acid, alkali, salt, active agent, etc.

3. Pipe specification model integration

The same engineering project must use pipes and fittings of the same brand, raw materials and the same standard size ratio (SDR), and use the same batch number of products from the same manufacturer to ensure that the characteristics of the pipes and fittings are consistent and the hot-melt connection is stable. When it is necessary to connect pipes and fittings of various brands of raw materials with similar characteristics, it is possible to test whether the quality of the connection is completely satisfactory.

4. Pipe connection

Because of the cooling effect of water, the quality of the melt is immediately jeopardized. The PE pipe joint cannot achieve the melt effect. Usually, it is not possible to carry out melt work or water work in rainy days. For the pipes and fittings of the welded end SDR, it is not necessary to use butt welding, but to use fusion socket connections or flange connections. In severe cold climates (below -5), safeguard measures or adjustment of construction techniques should be adopted when the Butt Fusion connection is operating. In addition, thermal expansion and cold contraction are serious, and engineering construction and application are performed in an environment where the temperature difference is not large.

5. Pipe cleaning

The construction site should pay attention to the cleanliness of the pipeline, and the construction area should be closed immediately during the construction of the sub-project to prevent water and dirt from entering the pipeline.

6. Pipe trench backfill

A part of the backfill above 70 mm from the top of the pipe can be backfilled mechanically, and a part of the backfill below the top of the pipe must be backfilled and reduced on both sides of the pipe at the same time. Otherwise, the PET pipe will be pressed unevenly, and there is a high possibility of deformation and deflection.

Flange connection between PE pipe and valve fittings

The maximum working pressure of PE100 water supply pipe is 1.6 MPa. This is also a pipe that has been attached great importance and marketing promotion at this stage, and is used to replace toxic and harmful iron pipes and galvanized pipes. The use of PE pipes is becoming more and more common, and the connection technology of such hot-melt injection molding pipes is a top priority. Therefore, the construction team must attach great importance to the connection quality of PE pipes to ensure the safety and smooth operation of the pipe network.

Process 1: According to the flange connection regulations, an injection-molded flange is welded to the end of the PE pipe to be connected;

Process 2: Put another steel flange piece into the top of the valve or metal pipe to be connected;

Process 3: According to the PE pipe connection regulations, carry out Butt Fusion connection or electrofusion connection between the flat end of the injection-molded flange connector (following pipe end) and the PE pipe;

Process 4: Put the flange gasket or sealing ring into the inner hole of the steel flange sheet of the metal pipe end and the flange connector (flange pipe end), and make the connecting surfaces cooperate closely with each other;

Process 5: Install the bolts, tighten the bolts evenly at the symmetrical parts, and tighten them.

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)