1.Modulus of elasticity: affects the stiffness and flexibility of the pipeline

The material of the PPR water pipe is polypropylene, the elastic modulus is 850MPa, the rigidity is good, and the flexibility is insufficient; while the PE water pipe is made of medium density polyethylene, the elastic modulus is only about 550MPa, and the flexibility is good, but the stiffness is insufficient; PE water pipe is used for building water supply In the field, the straightness of the pipeline is not good, it is easy to bend, it is easy to deform, and the pipeline is not beautiful. However, in the field of municipal water supply, due to the relatively more complex environment, the pipeline needs to have good flexibility to resist impact, so PE pipe is more suitable for the field of municipal water supply. In contrast, PPR water pipes are more suitable for the field of building water supply due to their good stiffness, poor flexibility, and low temperature brittleness.

2.Heat resistance, affecting the safe operation of pipelines

Although PE pipe has good low temperature performance, its high temperature performance is not as good as PPR water pipe. In the field of building water supply, especially home decoration, it is necessary to use hot water pipelines. However, according to the data, the heat-resistant temperature of conventional PE pipes is 60 °C, and the normal temperature of household water supply will be around 50 °C. During operation, the aging speed of the PE pipe will be greatly accelerated, not to mention that the advantageous temperature will be much higher than 50 °C, so the PE pipe is not suitable for the transportation of hot water, which is one of the reasons why it is generally not used for home improvement.

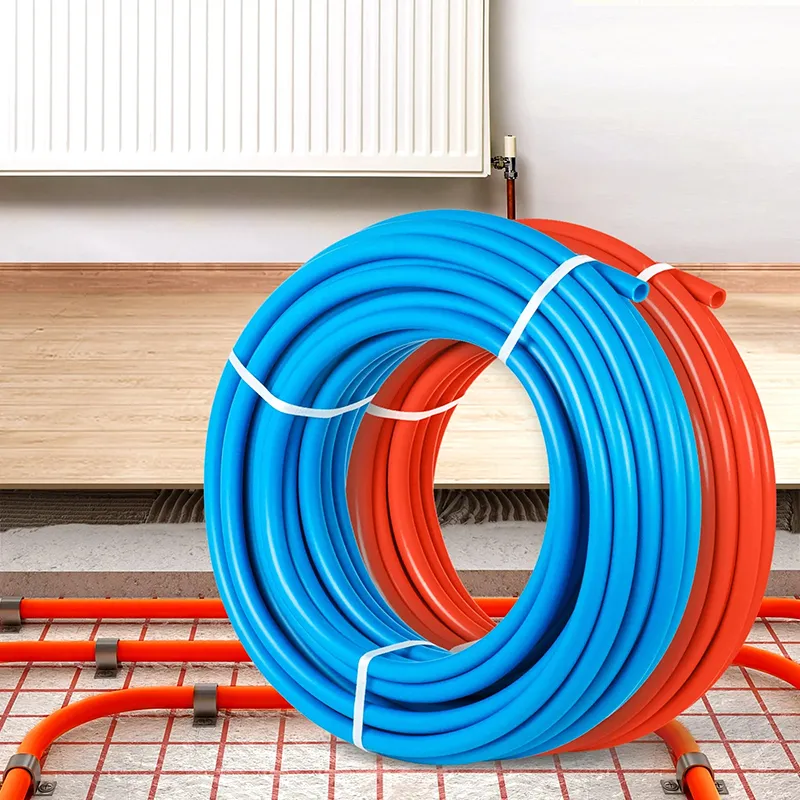

3.Thermal conductivity: affects the thermal insulation performance of the pipeline

The thermal conductivity of the PPR water pipe is 0.24, and the thermal conductivity of the PE water pipe is 0.42, which is nearly doubled. We know that the lower the thermal conductivity, the better the thermal insulation performance of the water pipe. If PE pipe is used in floor heating, it will give full play to its advantages. Good heat dissipation means better heat radiation effect, but when it is used in hot water pipes, it becomes its disadvantage. The surface temperature of the pipe is also higher, and it is easy to be hot. As a home improvement water supply, obviously PE pipe is not as reasonable as PPR pipe.

4.welding performance: affecting the difficulty of pipeline construction

In terms of welding performance, the flanging of PPR water pipe is round, while the flanging of PE water pipe is irregular, which is easy to be blocked; in addition, the welding temperature of PE pipe and PPR pipe is different, the PPR water pipe is 260 ℃, and the PE water pipe is 230 ℃. The special welding machine for PPR water pipes on the machine often causes over-welding, resulting in water leakage. Moreover, because the PE material is easy to oxidize, special tools must be used to scrape off the oxide skin on the surface before welding, otherwise, a truly integrated pipeline cannot be formed, and the pipeline is prone to water leakage. It can be seen that although PPR water pipes and PE water pipes can be welded by hot melt, they are not at the same level in terms of standardized operation difficulty. PPR water pipes are easier to operate and more convenient to construct. This is also the use of PPR water pipes for home decoration instead of PE. A very critical reason for the tube.

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)