The main ways to connect pipes are:

1. Use special adhesives for bonding (DN20~DN250), which is commonly used for indoor pipes

2. Use elastic sealing ring socket-type flexible connection (DN≥63), which is commonly used for outdoor buried pipes

3. Use injection-molded pipe fittings or flange connections with copper thread buckles, which are often used for connecting pipes and their accessories of other materials, sanitary appliances, etc.

241985.webp)

533995.webp)

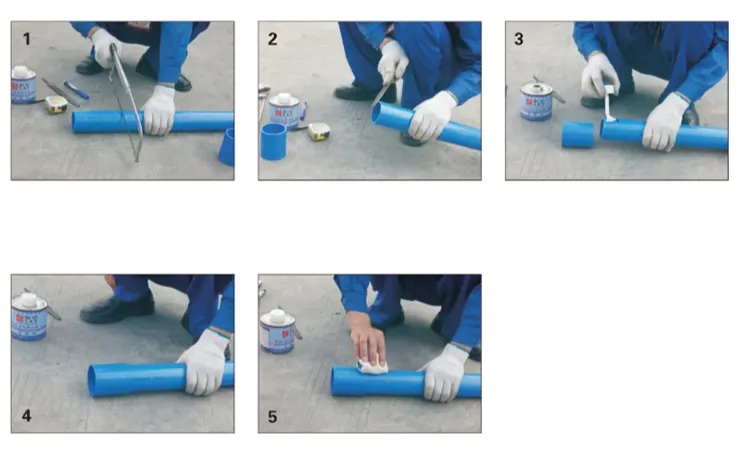

Adhesive connection should be carried out according to the following requirements:

1. PVC-U water supply pipe bonding joint is suitable for pvc pipes of DN20~DN250. When bonding, mark the length to be inserted according to the depth of the socket;

2. Before applying the adhesive, the bonding surface should be wiped clean with a dry cloth, and no dust, watermarks, or oil should be stuck. It should also be wiped clean with cotton yarn dipped in acetone, anhydrous alcohol, and other cleaning agents.

3. Use a brush to apply along the axial direction. The brushing action should be quick and the application should be uniform. The amount of adhesive applied should be appropriate. No omission or excessive application is allowed. During construction, apply the socket first and then the spigot. After using the adhesive, the bonding should be completed within 20 seconds. If the adhesive dries up during the operation, it should be removed and reapplied.

4. After applying the adhesive to the socket, the pipe end should be inserted into the socket immediately after aligning the axis and pushing it hard to the marked line. After insertion, rotate the pipe 1/4 turn, keep the applied external force unchanged within 30s (dn≤63) or 60s (dn75~dn200), and ensure the straightness and correct position of the interface.

5. After the socket joint is bonded, the excess adhesive at the joint should be wiped clean immediately with cotton yarn or dry cloth dipped in detergent, and left to stand until the interface solidifies. The curing time should be appropriately extended in winter construction, and the adhesive should not be applied too much to prevent "solvent cracking".

6. Pipe bonding should not be carried out in a very humid environment, and the operation site should be away from fire sources to prevent impact. It is not easy to operate under low-temperature conditions.

1. Use a fine-tooth saw. A cutter or a special PVC-U pipe cutting tool to cut the pipe evenly and vertically according to the required size.

2. Use a plate file to remove the brush and burrs on the broken end, and chamfer the ends. Before applying the adhesive, use a dry cloth to wipe off the debris, dust, water, and oil on the bonding surface of the socket.

3. Use a brush to evenly and quickly apply the special adhesive on the bonding surface of the socket.

4. Locate the center of the pipe and the pipe fitting, quickly insert the socket into the socket and turn 1/4 turn so that the adhesive is evenly distributed and cured.

5. Use a cloth to wipe off the excess adhesive on the surface of the pvc pipe, and the water pressure test can be carried out 24 hours after the connection number.

The elastic sealing ring plug-in flexible connection should be carried out according to the following requirements

1. The PVC-U water supply pipe DN63~DN630 adopts the socket-type elastic sealing ring connection form. The insertion length of the pipe end must leave the expansion caused by the temperature difference. The expansion is calculated and determined according to the closed temperature difference during construction. DN63~DN110 usually leaves 10mm, and DN110 and above leave 20mm;

2. When connecting, clean the foreign matter on the outside of the socket and the inner surface of the socket, and mark the insertion length; the socket pipe end should be chamfered. The thickness of the pipe end after chamfering is generally 1/3~1/2 of the pipe wall thickness, and the chamfer is generally 15°; (The company's expanded pipes have been chamfered and marked with the length mark line to be inserted)

3. Use lubricating liquids such as soapy water, detergent, etc. to lubricate the end of the socket and the outer surface of the elastic sealing ring. It is strictly forbidden to use butter and other oils as lubricants to prevent corrosion of the rubber ring.

4. Align the spigot of the connecting pipe with the socket, and use a pulling tool such as a wire plier and a hoist to insert the pipe into the marking line in a straight state. If the insertion resistance is too large, check whether the rubber ring is normal in time.

5. After the insertion process is completed, use a feeler gauge to check the correctness of the rubber ring position.

Steps for flexible connection with an elastic sealing ring insertion

1. Clean the inner and outer walls of both ends of the socket and spigot of the pvc pipe, and check whether the spigot pipe has been chamfered.

2. Take out the rubber ring, wipe it clean, and then insert it.

3. Apply lubricant (usually soapy water or detergent) to the inner surface of the socket and the insertion part of the spigot pipe end, and mark the insertion length mark on the spigot pipe end (leave an appropriate gap between the two pipes for expansion and contraction, about 10mm for small diameter and about 25mm for large diameter).

4. Socket and spigot pipe socketing (manual plugging for small diameters, and corresponding tools such as wire pliers, hoists, etc. for medium and large diameters).

477199.webp)

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)