Detailed explanation of the connection method between PVC and HDPE pipes

In pipeline construction, joining pipes of different materials is a common challenge. Among them, the connection between PVC (polyvinyl chloride) and HDPE (highdensity polyethylene) pipes is particularly important because there are significant differences in the physical and chemical properties of the two pipes. How to realize PVC to HDPE connection has become a problem that engineers need to solve. This article will introduce in detail several common methods to achieve PVC to HDPE connection and their advantages and disadvantages.

1. Comparison of material properties

① PVC pipe characteristics

Strong rigidity and good pressure resistance.

Higher tolerance to chemicals.

Commonly used in water supply and drainage pipelines, agricultural irrigation and industrial purposes.

② HDPE pipe characteristics

Strong flexibility and excellent impact resistance.

It has strong corrosion resistance and is suitable for transporting chemical liquids.

Can be used in underground pipelines and highpressure conveying systems.

Since the thermal expansion coefficients, connection methods and usage scenarios of the two pipes are different, PVC to HDPE connection needs to choose the appropriate solution according to the specific working conditions.

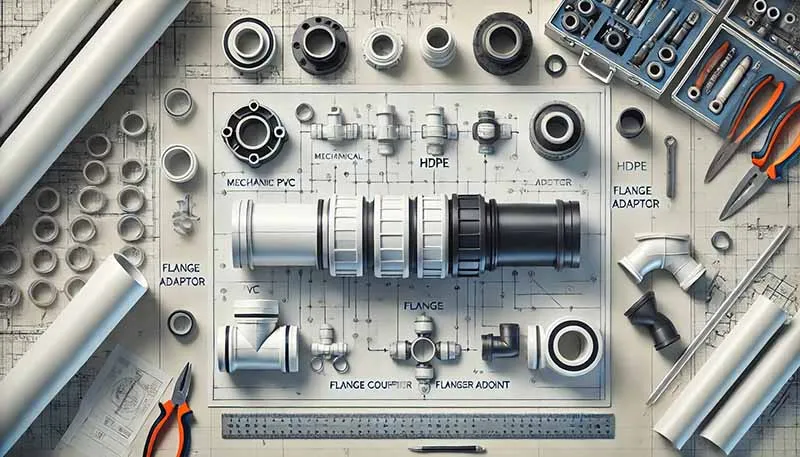

2. Connection method of PVC and HDPE

① Mechanical connection

Transition Fitting PVC and HDPE pipes can be connected using specially designed transition fittings. This kind of joint usually consists of a rubber sealing ring and a stainless steel clamp, which can ensure the sealing between pipes made of different materials.

Advantages Easy to install, no special tools required.

Disadvantages The applicable pressure range is limited, and longterm use may require regular inspection of sealing performance.

② Flange connection

Install flange adapters on the ends of PVC and HDPE pipes respectively, and fix the two sections of pipes together with bolts.

Advantages The flange connection is firm and suitable for largediameter pipes and highpressure scenarios.

Disadvantages Requires precise alignment of flanges, longer installation time.

③ Hot melt welding and transition joint combination

HDPE pipe can be connected to a transition joint by hot melt welding, and then connected to PVC pipe by threading or mechanical means.

Benefits Combines the strength of hot melt welding with the flexibility of mechanical joining.

Disadvantages Requires special welding equipment and technical support.

④Flexible joint

Secure PVC and HDPE pipes with clamps using flexible rubber joints. This method is particularly suitable for scenes that require vibration or displacement.

Advantages Strong adaptability, can relieve pipeline pressure.

Disadvantages Not recommended for use in highpressure scenarios.

3. Precautions when connecting PVC and HDPE

① Material Compatibility

When selecting joints, ensure chemical compatibility of materials to avoid seal failure due to corrosion or aging.

② Pressure and temperature requirements

Under high pressure or high temperature conditions, it is necessary to choose a connection method with stronger resistance, such as flange connection or hot melt welding.

③ Construction Specifications

During the installation process, construction specifications must be strictly followed to ensure that the sealing ring is installed correctly and the clamp is tightened in place.

④Regular Maintenance

After the PVC to HDPE connection is completed, the sealing performance of the connection should be checked regularly, especially in the mechanical connection mode, to avoid leakage or breakage.

Application examples of PVC to HDPE Connection

The connection between PVC and HDPE pipes has been widely used in many industries and scenarios due to their different material properties. The following are some common specific application scenarios to explain why PVC to HDPE connection is needed and its advantages.

1. Municipal Engineering

Background Requirements

Municipal sewage systems usually require corrosion-resistant and high-pressure resistant pipes to handle complex drainage and water delivery tasks. In these projects, PVC pipes are usually used for surface drainage, while HDPE pipes are mostly used for underground or long-distance water delivery pipelines.

Application Examples

In urban rainwater drainage systems, PVC pipes are used to collect surface rainwater, and then HDPE pipes are used for long-distance transportation.

In sewer renovation, old PVC drainage pipes and new HDPE pipes need to be connected to achieve seamless connection.

Advantages

PVC pipes are rigid and suitable for short-distance drainage; HDPE pipes are flexible and suitable for underground and earthquake-resistant scenarios.

2. Agricultural irrigation

Background requirements

Agricultural irrigation systems usually consist of two parts trunk pipes and branch pipes. The trunk pipes require higher pressure resistance, while the branch pipes need to flexibly adapt to the terrain. The characteristics of PVC and HDPE pipes just meet these requirements.

Application examples

In large irrigation systems, PVC pipes are used as main pipes to transport high-flow water sources. HDPE pipes are used as branch pipes through PVC to HDPE connection and are flexibly distributed in farmland.

In drip irrigation systems, the transition connection between the PVC main pipe and the HDPE micro-pipe requires the use of mechanical joints or flexible joints.

Advantages

HDPE pipes are flexible and can be laid in a bent manner, which is suitable for complex farmland terrain; PVC pipes are corrosion-resistant and can be used for long-term irrigation water transportation.

3. Industrial pipelines

Background requirements

Industrial pipelines need to meet the requirements of corrosion resistance, high pressure and long life at the same time. Usually, different materials of pipelines need to be combined to balance cost and performance.

Application examples

In chemical plants, PVC pipes are used to transport low-temperature or room-temperature chemical liquids, and connected to HDPE pipes through PVC to HDPE connection to complete long-distance transportation or underground pipelines.

In industrial sewage treatment equipment, PVC pipes are used to connect treatment equipment, and HDPE pipes are used to discharge sewage to remote treatment pools.

Advantages

PVC pipes have good tolerance to acids and alkalis and are suitable for chemical medium transportation; HDPE pipes are pressure-resistant and impact-resistant, and are suitable for high-pressure transportation scenarios.

4. Water supply and drainage systems

Background requirements

Water supply and drainage systems often need to combine pipes of different materials in the internal and external environments of buildings, especially in long-distance transportation and underground construction.

Application examples

In the underground drainage system of urban buildings, the PVC drainage pipe is connected to the buried HDPE pipe through the PVC to HDPE connection.

In the community water supply project, the PVC pipe is used as a branch pipe laid on the ground and connected to the buried HDPE main pipe through a transition joint.

Advantages

PVC pipes are easy to install and low in cost, suitable for short-distance distributed pipelines; HDPE pipes have a long service life and are suitable for long-distance underground water transportation.

5. Temporary water use and mobile pipeline systems

Background requirements

In temporary construction sites, disaster relief areas or mobile pipeline systems, the use of flexible and durable HDPE pipes combined with PVC pipes can quickly deploy water supply or drainage systems.

Application examples

In construction, PVC pipes are used as fixed pipes to connect to water sources, and connected to HDPE mobile pipes through PVC to HDPE connection to transport water to the construction site.

In the emergency relief water supply system, HDPE pipes are connected to PVC pipes through flexible connections to quickly establish a water supply network.

Advantages

HDPE pipes are easy to move and suitable for rapid deployment; PVC pipes are easy to install and can be used as temporary fixed pipes.

From the above scenarios, it can be seen that PVC to HDPE connection is of great significance in municipal engineering, agricultural irrigation, industrial transportation, water supply and drainage systems, and temporary water use. This connection method can give full play to the characteristics of both PVC and HDPE pipes and provide reliable solutions for different working conditions.

Whether it is in municipal engineering, agricultural irrigation or industrial fields, mastering the technical points of PVC to HDPE connection can provide a strong guarantee for the quality of the project.

I hope the content of this article can provide readers with reference and help in practical operations. Readers who need PVC pipes, HDPE pipes and accessories can click contact us to obtain product details and quotations.

210.webp)

241.webp)

505.webp)

891.webp)

430.webp)

552.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)