Polyethlene (PE) pipes for water supply detailed parameters

Material: PE80 or PE100

Pressure Rating: 0.6MPa, 0.8MPa, 1.0MPa, 1.25MPa, 1.6MPa

Place of Origin: China

Size: 20mm ~ 1600mm

Standard: GB/T13663-2000, ISO4427-2007

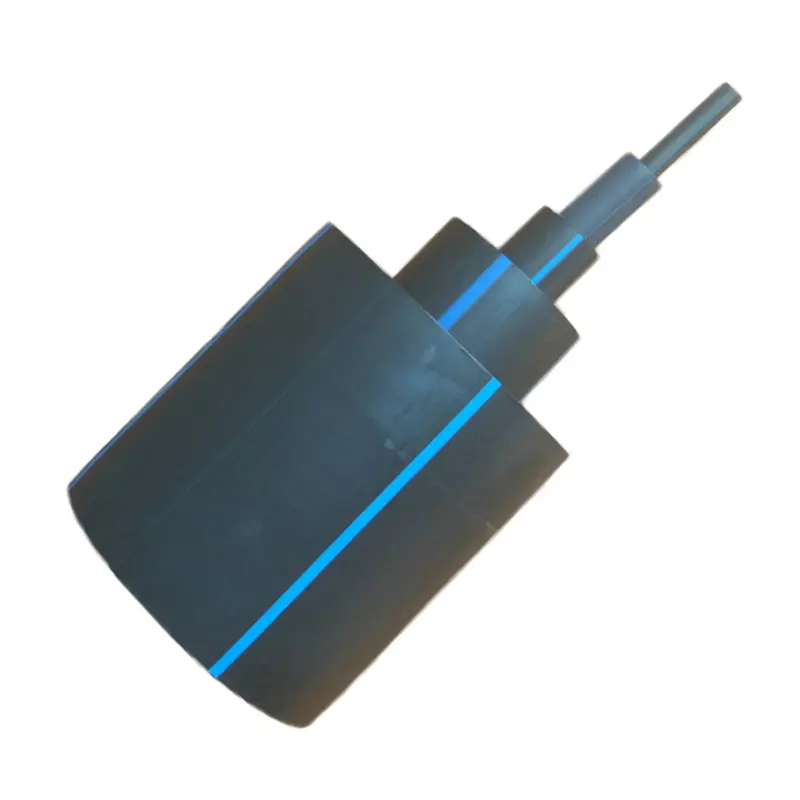

Colors: Blue, Black with blue stripes, Other colors are also available upon request

Applications:Municipal water supply, Commercial & Residential water supply , Industrial liquids transportation, Sewage treatment

Service Life: 50 years at rated temperature and pressure

Working Temperature: under 40℃

Price:

Payment items: T/T L/C

Port: Qingdao

Pipe Connection:The connection types of PE water pipe and PE gas pipe include electro fusion and butt fusion.

Supply Polyethylene (PE) pipes for water G specification

SDR26 | SDR21 | SDR17 | |||

0.6MPa | 0.8MPa | 1MPa | |||

EN/mm | ㎏/m | EN/mm | ㎏/m | EN/mm | ㎏/m |

/ | / | / | / | / | / |

/ | / | / | / | / | / |

/ | / | / | / | 2.3 | 0.23 |

/ | / | 2.3 | 0.29 | 2.4 | 0.30 |

2.3 | 0.37 | 2.4 | 0.38 | 3 | 0.46 |

2.5 | 0.50 | 3 | 0.59 | 3.8 | 0.74 |

2.9 | 0.69 | 3.6 | 0.85 | 4.5 | 1.04 |

3.5 | 1.00 | 4.3 | 1.21 | 5.4 | 1.50 |

4.2 | 1.47 | 5.3 | 1.82 | 6.6 | 2.23 |

4.8 | 1.89 | 6 | 2.33 | 7.4 | 2.84 |

5.4 | 2.39 | 6.7 | 2.92 | 8.3 | 3.57 |

6.2 | 3.13 | 7.7 | 3.82 | 9.5 | 4.66 |

6.9 | 3.89 | 8.6 | 4.80 | 10.7 | 5.89 |

7.7 | 4.83 | 9.6 | 5.95 | 11.9 | 7.27 |

8.6 | 6.07 | 10.8 | 7.52 | 13.4 | 9.22 |

9.6 | 7.52 | 11.9 | 9.21 | 14.8 | 11.30 |

10.7 | 9.38 | 13.4 | 11.62 | 16.6 | 14.19 |

12.1 | 11.95 | 15 | 14.60 | 18.7 | 17.97 |

13.6 | 15.10 | 16.9 | 18.54 | 21.1 | 22.87 |

15.3 | 19.15 | 19.1 | 23.64 | 23.7 | 28.91 |

17.2 | 24.21 | 21.5 | 29.90 | 26.7 | 36.62 |

19.1 | 29.87 | 23.9 | 36.89 | 29.7 | 45.25 |

21.4 | 37.44 | 26.7 | 46.17 | 33.2 | 56.69 |

24.1 | 47.44 | 30 | 58.33 | 37.4 | 71.80 |

27.2 | 60.39 | 33.9 | 74.38 | 42.1 | 91.25 |

30.6 | 76.49 | 38.1 | 94.28 | 47.4 | 115.70 |

34.4 | 96.74 | 42.9 | 119.29 | 53.3 | 146.36 |

38.2 | 119.37 | 47.7 | 147.38 | 59.3 | 180.89 |

45.9 | 171.92 | 57.2 | 212.12 | 67.9 | 249.16 |

53.5 | 233.84 | 66.7 | 288.43 | 82.4 | 351.92 |

61.2 | 305.72 | 76.2 | 376.66 | 94.1 | 459.34 |

69.1 | 388.24 | 85.7 | 476.40 | 105.9 | 581.29 |

76.9 | 479.75 | 95.2 | 588.11 | 117.6 | 717.31 |

86 | 603.67 | 107.2 | 744.92 | / | / |

95.6 | 745.69 | 119.1 | 919.53 | / | / |

Polyethylene (PE) pipes for water welding principle

The general principle of the PE pipe welding is that the polyethylene melts in 190-240 ℃ range(generally, melting temperature of different grades of raw materials is also different), then if the melting pipes can be fully contacted with the proper pressure (the pressure of electro fusion comes from expansion of polyethylene itself in the process of melting), after cooling they can be melted into a entirety firmly. Flange connection or plastics-steel transition joint should be used when PE water pipe or PE gas pipe connects with pipe, valve and fittings of other materials

Advantages of Polyethylene (PE) pipes for water:

Polyethylene (PE) pipes Non-toxic: no heavy metal additives, no dirt, no secondary pollution caused by bacterium

Corrosion Resistant: resist chemical mediator corrosion and electron chemical corrosion

Polyethylene (PE) pipes are Low Flow Resistance: smooth inner wall and low friction result in low flow resistance and high volume

Excellent Flexibility: can be coiled

Polyethylene (PE) pipes are Easy Installation: light weight and can be carried and installed easily

Polyethylene (PE) pipes are Long service life: safe for more than 50 years at rated temperature and pressure

Various connection type: butt fusion joint, electro fusion joint

Polyethylene (PE) pipes are Recycled and Environment-friendly

766.webp)

536.webp)

235.webp)

476.webp)

420.webp)

720.webp)

294.webp)

146.webp)