This video is a demonstration of our HDPE Inspection Chamber products in the factory

Product parameters for our PE inspection chamber manhole

Item | PE Inspection Chamber Manhole |

Material | PE |

Size | ID 300mm-1000mm |

Standard | GB/T13663-2000, ISO4427-2007 |

Color | Blue Black with blue stripes |

Application | 1. Municipal water supply 2. Chemical liquid transportation 3. Mud transportation during mining 4. Gardening 5. Concrete/Steel tubing replacement |

Advantages | 1. Convenient in transportation 2. Good corrosion resistance and chemical-proof 3. Small liquid resistance 4. Long life-spans 5. Excellent in low temperature impact resistance 6. Reliable connection 7. Superior stress cracking resistance |

Payment items | T/T L/C |

Port | Qingdao |

Information of our polyethylene (PE) inspection chamber/ manhole

Polyethylene (PE) is a thermoplastic resin obtained by the polymerization of ethylene. In industry, copolymers of ethylene with small amounts of alpha-olefins are also included. Polyethylene is odorless, non-toxic, feels like wax, has excellent low temperature resistance (minimum operating temperature can reach -100~-70°C), good chemical stability, and can resist most acid and alkali erosion (not resistant to oxidation nature acid). It is insoluble in common solvents at room temperature, with low water absorption and excellent electrical insulation.

Polyethylene (PE) inspection chamber(manhole) adopts a single injection molding process, with strong corrosion resistance, long service life, flexible connection without leakage, smooth and smooth pipe inner wall without blockage, easy installation and high efficiency, strong adaptability to geological settlement, saving valuable land resources and other characteristics, is a kind of water-saving, land-saving, material-saving, energy-saving building materials environmental protection products.

Advantages of our polyethylene (PE) inspection chamber/ manhole

The functional advantages of Polyethylene (PE) inspection chamber(manhole) mainly have five points: land saving, energy saving, water saving, material saving, and environmental protection.

(1) Acid and alkali corrosion resistance, aging resistance, long service life.

(2) Safety and environmental protection.

The material of the polyethylene (PE) inspection Chamber is high-density polyethylene polyethylene (PE) that is non-toxic and odorless, and can be recycled after use. It belongs to chemical environmental protection building materials and conforms to the national policy of environmental protection.

(3) Uniform settlement, pressure resistance.

The flexible connection between the pipeline and the chamber seat, the clay of the pipe and the chamber seat moves together, which solves the problem of uneven settlement caused by the connection between the traditional inspection chamber and the polyethylene (PE) pipe, and effectively prevents the ground from collapsing.

(4) The construction is convenient and fast.

The use of split assembly structure, chamber bore can be cut and adjusted on site, adapt to various installation depth requirements, effectively reduce costs, greatly improve the construction progress, shorten the construction period is more than 10-20 times that of traditional inspection chambers; And can be built around the clock, brick inspection Chambers and other cement brick chambers cannot be compared.

(5) Efficient drainage.

The inner wall is smooth and smooth, with a diversion trough, the dirt is not easy to stay, reducing the possibility of clogging, has excellent drainage performance, and the rain sewage discharge rate is 1 to 3 times that of the traditional inspection chamber.

(6) Light weight, easy to transport and install, reliable performance, strong bearing capacity; Strong adaptability and complete varieties, can arbitrarily adjust the height of the chamber bore and punch holes in the cylinder body, adjust the direction, to meet all the needs of the project installation.

(7) The comprehensive cost is low, the maintenance cost is small, and it has more advantages than the traditional inspection chamber; It can be recycled and recycled, which has huge social benefits.

(8) Good sealing performance, anti-leakage.

Because of the use of flexible connection: flexible and convenient, can overcome the harsh construction environment of wind and dust, sand ash: good sealing can eliminate rainwater leakage and leakage to prevent groundwater pollution. It can also overcome the difficulty of not being able to repeat the insertion due to the increase in pavement height.

(9) Save materials.

Polyethylene (PE) inspection chambers replace red brick cement with polymer resin as processing materials, saving topsoil resources; The specifications used in the construction community have been reduced, which greatly saves the land space occupied by the burial of the inspection chamber.

805686.webp)

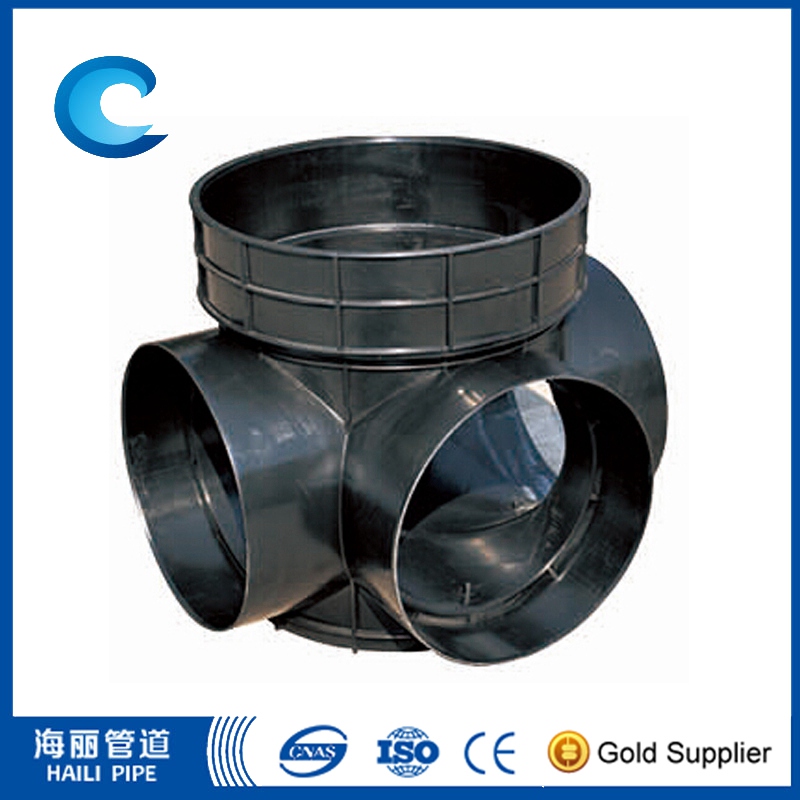

The composition of polyethylene (PE) inspection chamber/ manhole

PE inspection chamber/ manhole consists of chamber seat, chamber bore, chamber cover or protective cover seat and inspection chamber/ manhole accessories.

The chamber bore of the inspection chamber adopts buried drainage pipes, such as flat-wall solid-wall pipes and double-wall corrugated pipes;

Inspection manhole covers can be PVC-U manhole covers, cast iron inspection manhole covers, composite material inspection manhole covers, and steel fiber reinforced concrete inspection manhole covers;

1. The chamber bore adopts HDPE double-wall corrugated pipe, which has the same compression resistance and anti-settling coefficient as the buried pipeline. (HDPE material cold resistance at -40 ℃)

2. This PE inspection chamber/ manhole is suitable for inner diameter series HDPE double-wall corrugated pipes.

3. The pipeline and the plastic inspection chamber should be connected by a flexible sealing rubber ring. Advantages: Anti-settling and stretching, anti-permeability; Avoid the joints being pulled or broken when the heat-shrinkable sleeve is used to connect and settle.

4. Since the outer diameter of the inner diameter series double-wall corrugated pipes is different from each manufacturer, the outer diameters of different pipes are dimensioned by sealing rubber rings of different thicknesses, and are connected with the flexible sockets of the plastic inspection chambers.

5. The ring rigidity requirements of the chamber bore and the buried pipeline are the same (ring rigidity ≥8KN/m2) to achieve uniform load bearing and uniform settlement.

989.webp)

664.webp)

536.webp)

504.webp)

832.webp)

294.webp)

476.webp)

420.webp)

146.webp)