Unique functions and classification of tees

Functional uses of tees

Tee fittings, as an important connector in the pipeline system, have an irreplaceable role. It is usually used at the branch pipe of the main pipeline, and its main function is to change the direction of the fluid.

Imagine that the urban water supply system is like a huge "water network", and the tees are like key "hubs" in it.

On the main water supply pipeline, many branch pipelines can be connected through the tee to transport water to various communities and buildings to meet people's daily water needs.

In the industrial field, the pipeline system of the petroleum and chemical industries is also inseparable from the tee. In the process of oil refining, crude oil needs to go through a series of complex processing processes. In this process, the tee can connect the pipelines at different processing stages, so that the crude oil and its processed products flow in different pipeline branches to complete various reactions and processing steps.

In chemical production, various chemical raw materials and products also rely on tees to transport and distribute between the main pipeline and the branch pipeline to ensure the smooth progress of the production process.

Multiple classifications of tee fittings

Classification by pipe diameter: can be divided into equal-diameter tee fittings and reducing-diameter tee fittings. The ends of the pipes of equal-diameter tees are all the same size, just like three roads of the same width intersecting together. In some pipeline systems that require uniform diversion or confluence, equal-diameter tees can evenly distribute the fluid between the three pipes, achieve flow balance, and ensure the flow consistency of each branch pipe. They are widely used in some industrial equipment, metallurgy, petrochemical, papermaking and other fields with strict requirements on flow distribution.

For example, in the pulp conveying system of a paper mill, the use of equal-diameter tees can ensure that each paper machine receives an equal amount of pulp supply and ensure the consistency of paper quality.

The main pipe size of the reducing tee is the same, while the pipe size of the branch pipe is smaller than that of the main pipe. It is suitable for connecting pipes of different diameters to achieve transitions between pipes of different diameters and changes in fluid flow direction. It is often used in liquid conveying equipment and pipeline systems, chemical equipment and pipeline systems, oilfield wear handling equipment and other fields.

For example, in the water supply and drainage system of a building, when connecting the main water supply pipe to the branch pipes on each floor, a reducing tee may be used to connect the main pipe with a larger diameter to the branch pipe with a smaller diameter to meet the water demand of different areas.

According to the process classification: there are mainly two types: hydraulic bulging and hot pressing. Hydraulic bulging is a forming process that expands the branch pipe through axial compensation of metal materials.

A special hydraulic press is used to inject liquid into a tube billet with the same diameter as the tee. The two horizontal side cylinders of the hydraulic press are synchronously aligned to extrude the tube billet. After being squeezed, the volume of the tube billet becomes smaller, and the pressure of the liquid in the tube billet increases as the volume of the tube billet decreases. When the pressure required for the branch pipe to bulge is reached, the metal material flows along the inner cavity of the mold under the dual action of the side cylinder and the liquid pressure in the tube billet and bulges the branch pipe.

This process can be formed in one time, with high production efficiency, and the wall thickness of the main pipe and shoulder of the tee is increased. It is suitable for carbon steel, alloy steel, stainless steel and some non-ferrous metal materials (such as copper, aluminum, titanium, etc.) with relatively low cold work hardening tendency. At present, it is mainly used for the manufacture of tees with standard wall thickness less than DN400 in China.

Hot pressing forming is to flatten the tube billet larger than the diameter of the tee to about the size of the tee diameter, and open a hole at the position of the stretched branch pipe; the tube billet is heated and placed in the forming die, and the punch die for stretching the branch pipe is installed in the tube billet; the tube billet is radially compressed under the action of pressure, and the metal flows in the direction of the branch pipe during the radial compression process and forms the branch pipe under the stretching of the punch die. The whole process is formed by radial compression of the tube billet and stretching of the branch pipe.

Unlike the hydraulic bulging tee, the metal of the hot pressing tee branch pipe is compensated by the radial movement of the tube billet, so it is also called radial compensation process. Due to the use of heating and then pressing the tee, the tonnage of equipment required for material molding is reduced, and the adaptability to materials is wide. It is suitable for low-carbon steel, alloy steel, and stainless steel materials, especially large diameter and thick wall tees, which usually adopt this extrusion molding process.

According to material classification: there are carbon steel tees, cast steel tees, alloy steel tees, stainless steel tees, copper tees, aluminum alloy tees, and plastic tees (such as PVC, PPR, etc.).

Carbon steel tee fittings are relatively low in price and have good mechanical properties. They are widely used in general industrial pipelines and water and gas pipelines in construction projects.

Cast steel tees have high strength and hardness and are often used in some occasions with high strength requirements.

Alloy steel tees have excellent comprehensive performance and can adapt to harsh environments such as high temperature and high pressure. They play an important role in petrochemicals, electric power and other fields.

Stainless steel tees have strong corrosion resistance and are favored in industries with high requirements for hygiene and corrosion resistance such as chemical, food, and medical. For example, in the pipeline system of food processing plants, stainless steel tees are used in large quantities to ensure the safety and hygiene of food and prevent pipelines from rusting and contaminating food.

Copper tee fittings have good thermal conductivity and are often used in heating systems, etc. They can better transfer heat and ensure the heating effect.

Aluminum alloy tee fittings are light in weight and have certain corrosion resistance. They are used in some occasions where weight is required, such as some pipeline systems in the aerospace field. Plastic tee fittings are cheap and easy to install. They are widely used in home water supply and drainage pipes. PPR plastic tees are commonly used pipe fittings in home decoration.

Classification by connection method: including threaded tee fittings, welded tee fittings, flanged tee fittings, socket tee fittings, etc. Threaded tee fittings connect the tees to the pipes through threads, which is convenient to install and disassemble. They are often used in some low-pressure and small-diameter pipe systems, such as household tap water pipe connections. Threaded tee fittings may be used to connect some small faucets to pipes.

Welded tee fittings are connected to pipes by welding. They have high connection strength and good sealing. They are suitable for high-pressure, high-temperature and pipeline systems with strict sealing requirements, such as some pipeline connections in the petrochemical industry.

The flange connection tee fitting uses a flange to connect the tee to the pipe, which is easy to disassemble and repair. It is suitable for various large-scale pipeline systems and parts that need frequent maintenance. Flange connection tees are often seen in some large industrial equipment pipeline connections.

The socket connection tee is to insert one end of the tee into the pipe and then seal it with a sealing material. The operation is relatively simple. It is often used in some small-diameter pipes and occasions with high installation speed requirements, such as some connection parts of building drainage pipes.

323248.webp)

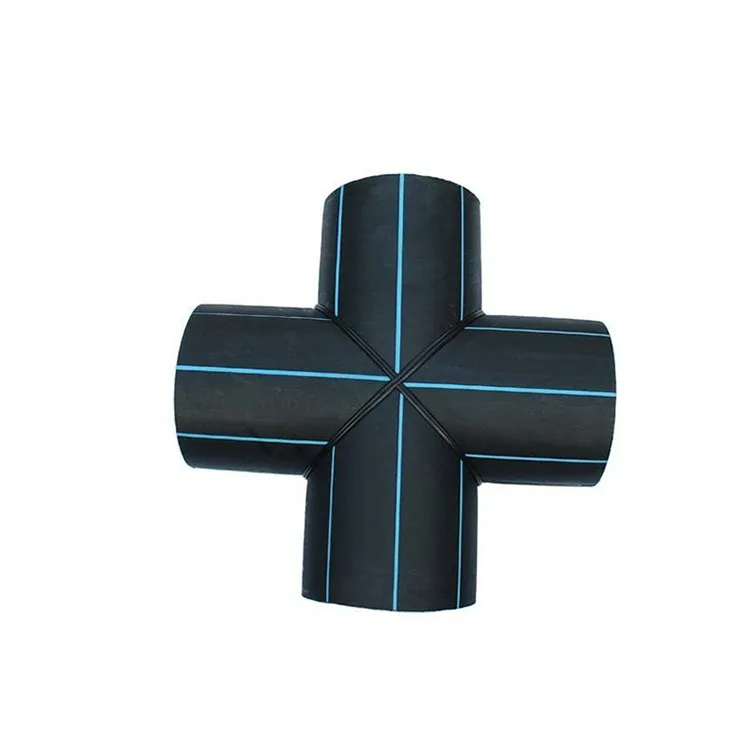

The special role and type of the cross fittings

The purpose of the cross fittings

As a special connector in the pipeline system, the cross fittings has a unique role. It is used at the branch pipe of the main pipeline. It is a pipe fitting with four ports that can realize the connection of four pipelines and allow fluids or gases to flow freely in four directions.

In some large-scale industrial production, such as petrochemical enterprises, the production process involves the transportation and processing of a variety of different media, and the cross fittings plays a vital role. It can distribute and mix different raw materials, semi-finished products or finished products between different pipelines to ensure the smooth progress of the production process.

In the city's water supply and drainage system, the cross fittings is also indispensable. When it is necessary to divert water from a main water supply pipe to multiple branch pipes in different directions to meet the water demand of different areas, the cross fittings can be used. It can also connect sewage pipes from different directions in the sewage treatment system to achieve centralized sewage treatment.

In the ventilation and air-conditioning system of the building, the cross fittings can be used to connect ventilation ducts in different directions so that the air can be evenly distributed to each room to ensure the circulation and comfort of indoor air.

Classification of cross fittings

According to the pipe diameter size: the cross fittings can be divided into equal-diameter cross fittings and different-diameter cross fittings. The ends of the equal-diameter cross fittings are all the same size, just like four roads of the same width intersecting together. In some pipeline systems that require uniform diversion or confluence, the equal-diameter cross fittings can evenly distribute the fluid between the four pipes, achieve flow balance, and ensure the consistency of the flow of each branch pipe. It is widely used in some industrial equipment, metallurgy, petrochemical, papermaking and other fields that have strict requirements on flow distribution.

For example, in the pulp conveying system of a paper mill, the use of equal-diameter cross fittingses can ensure that each paper machine receives an equal amount of pulp supply and ensure the consistency of paper quality.

The main pipe size of the reducing cross fittings is the same, while the branch pipe size is smaller than the main pipe size. It is suitable for connecting pipes of different diameters to achieve transitions between pipes of different diameters and changes in fluid flow direction. It is often used in liquid conveying equipment and pipeline systems, chemical equipment and pipeline systems, oil field wear handling equipment and other fields.

For example, in the water supply and drainage system of a building, when connecting the main water supply pipe to the branch pipes on each floor, a reducing cross fittings may be used to connect the main pipe with a larger diameter with the branch pipe with a smaller diameter to meet the water demand of different areas.

According to the manufacturing method, there are top-made cross fittingses, pressed cross fittingses, forged cross fittingses, cast cross fittingses, etc. The top-made cross fittings is a cross fittings-shaped cross fittings that is made of materials under a certain pressure through a specific mold and process. Its production efficiency is relatively high and it is suitable for mass production of some cross fittingses that do not require particularly high precision.

Pressed cross fittings is to use a press to directly press the tube into shape in the mold. This method can produce a cross fittings with high precision and good surface quality, which is often used in some pipeline systems with high quality requirements. Forged cross fittings is made by forging process, with dense structure and good mechanical properties. It is often used in some high-pressure pipeline connections with high strength and quality requirements.

Casting cross fittings is to pour liquid metal into a specific mold, cool and solidify to form a cross fittings. It can produce a complex shape of the cross fittings, but there may be internal defects. It is usually used in some occasions where the precision and performance requirements are not particularly high, such as some ordinary building drainage pipe cross fittings.

According to material classification: there are carbon steel cross fittings, cast steel cross fittings, alloy steel cross fittings, stainless steel cross fittings, copper cross fittings, aluminum alloy cross fittings, plastic cross fittings (such as PVC, PPR, etc.). Carbon steel cross fittings is relatively low in price and good in mechanical properties. It is widely used in general industrial pipelines and water and gas pipelines in construction projects. Cast steel cross fittings has high strength and hardness, and is often used in some occasions with high strength requirements.

Alloy steel cross fittings has excellent comprehensive performance, can adapt to harsh environments such as high temperature and high pressure, and plays an important role in petrochemical, electric power and other fields.

Stainless steel cross fittings has strong corrosion resistance and is favored in industries with high requirements for hygiene and corrosion resistance such as chemical, food, and medical. For example, in the pipeline system of food processing plants, stainless steel cross fittings is used in large quantities to ensure the safety and hygiene of food and prevent the pipeline from rusting and contaminating food.

Copper cross fittings has good thermal conductivity and is often used in heating systems, etc. It can better transfer heat and ensure the heating effect. Aluminum alloy cross fittings is light and has certain corrosion resistance. It will be used in some occasions with weight requirements, such as some pipeline systems in the aerospace field.

Plastic cross fittings is cheap and easy to install. It is widely used in water supply and drainage pipes for home decoration. PPR plastic cross fittings is a commonly used pipe fitting in home decoration.

Classification by connection method: including threaded connection cross fittings, welding cross fittings, flange connection cross fittings, socket connection cross fittings, etc. The threaded cross fittings is used to connect the cross fittings with the pipe through threads. It is easy to install and disassemble. It is often used in some low-pressure and small-diameter pipe systems, such as the connection of household tap water pipes. The threaded cross fittings may be used to connect some small faucets with pipes.

The welded cross fittings is to connect the cross fittings with the pipe by welding. It has high connection strength and good sealing. It is suitable for high-pressure, high-temperature and pipe systems with strict sealing requirements, such as some pipe connections in the petrochemical industry.

The flange-connected cross fittings uses a flange to connect the cross fittings with the pipe, which is easy to disassemble and repair. It is suitable for various large-scale pipe systems and parts that need to be frequently inspected. Flange-connected cross fittings can often be seen in some large industrial equipment pipe connections.

The socket-connected cross fittings is to insert one end of the cross fittings into the pipe and then seal it with a sealing material. The operation is relatively simple. It is often used in some small-diameter pipes and occasions with high installation speed requirements, such as some connection parts of building drainage pipes.

Key points for reasonable selection of pipe fittings

In the actual construction and maintenance of pipeline systems, it is crucial to correctly select pipe fittings such as elbows, tees, and cross fittingses.

First, the working pressure of the pipeline system must be considered. Pipe fittings of different pressure levels can withstand different pressures. If the pressure level of the selected pipe fittings is lower than the working pressure of the pipeline system, it may cause safety accidents such as pipe rupture and leakage. Therefore, it is necessary to select pipe fittings that can withstand the corresponding pressure according to the actual pressure of the pipeline.

Temperature is also a key factor. High temperature environment may change the material properties of pipe fittings. For example, carbon steel is easy to oxidize and deform at high temperature. Therefore, in high-temperature pipeline systems, it is necessary to select pipe fittings with good high-temperature resistance, such as stainless steel or alloy steel. In low-temperature environments, some pipe fittings may become brittle, affecting their strength and toughness, so materials suitable for low-temperature environments should be selected.

The properties of the fluid should not be ignored. Pipes that transport corrosive media must select pipe fittings with strong corrosion resistance, such as stainless steel, alloy steel, or pipe fittings with anti-corrosion coatings to prevent pipe fittings from being corroded and damaged, ensuring the service life of the pipeline system. If the fluid contains impurities such as particles, the wear resistance of the pipe fittings also needs to be considered. For example, ceramic-lined elbows have good wear resistance and are suitable for conveying fluids containing solid particles.

The size of the pipe diameter also directly affects the selection of pipe fittings. Pipes of different diameters need to match pipe fittings of corresponding sizes to ensure the tightness of the connection and the smooth flow of the fluid.

Equal-diameter tees and cross fittingses are suitable for connecting pipes of the same diameter, while different-diameter tees and cross fittingses are used for transitional connections of pipes of different diameters. At the same time, the curvature radius and connection method of the pipe fittings also need to be reasonably selected according to specific engineering requirements and installation environment.

The correct selection of pipe fittings is a key link to ensure the normal operation of the pipeline system, ensure safety, and extend the service life. It is necessary to comprehensively consider many factors and make careful decisions.

981.webp)

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)