The reason why the PE water supply pipe will burst

Everyone knows that PE water supply pipes can be used for water delivery projects. Although the PE water supply pipe itself has excellent characteristics, due to the interference of various elements in the new project, the PE water supply pipe will also crack. The reasons for the cracking will be described in detail below.

The reason for the bursting of the PE water supply pipe is the cracking of the butt fusion connection. The length of the pipe is relatively limited, so a welding process is required to weld pipes of different lengths in a water conveyance project. If the main parameters used in welding do not conform to the specific main parameters of the pipeline, or if the actual welding operation of the worker is not timely, the butt fusion connection of the PE water supply pipe will likely crack.

There is no problem with the thermal fusion joint of the PE water supply pipe, but the pipe body of the PE water supply pipe is cracked, and a pressure test or pipeline quality inspection should be carried out. If the results of the pressure test are within the specification, it is a product quality problem with the pipeline itself, such as brittle cracking or plastic cracking at the fracture.

Interference of temperature on the quality of PE water supply pipes: Temperature is the main factor that interferes with the plasticization and production of plastic pipes. If the temperature is too low, the actual effect of plasticization is not very good, and if the temperature is too high, the raw materials are very easy to decompose. Temperature control should be based on the initial recipe, extruder and die structure, screw speed, and other factors. In the production and processing of rigid PVC pipes, because the production and processing temperature is close to the decomposition temperature, the raw material temperature at each point should be strictly controlled in the production process. In addition, pay attention to the deviation of the thermometer and the location of the measurement point.

The interference of screw speed on the quality of PE water supply pipe: the selection of screw speed directly interferes with the production volume and quality. The screw speed depends on the size of the extruder and the size of the upper tube diameter. However, the waiting time of the raw material in the screw is short, the high frictional heat makes the inner wall of the tube not smooth and the compressive strength of the tube is reduced.

No matter what the sudden reason is, it is an indisputable fact that the PE water supply pipe bursts. Construction companies need to respond quickly based on many years of work experience and the above analysis to reduce losses and ensure the quality of construction.

What are the design requirements for PE pipes?

PE pipe has comprehensive advantages such as safety, environmental sanitation, convenient construction, and long service life, and has long become an ideal pipe for urban water supply. Practically understand the design requirements of PE pipes:

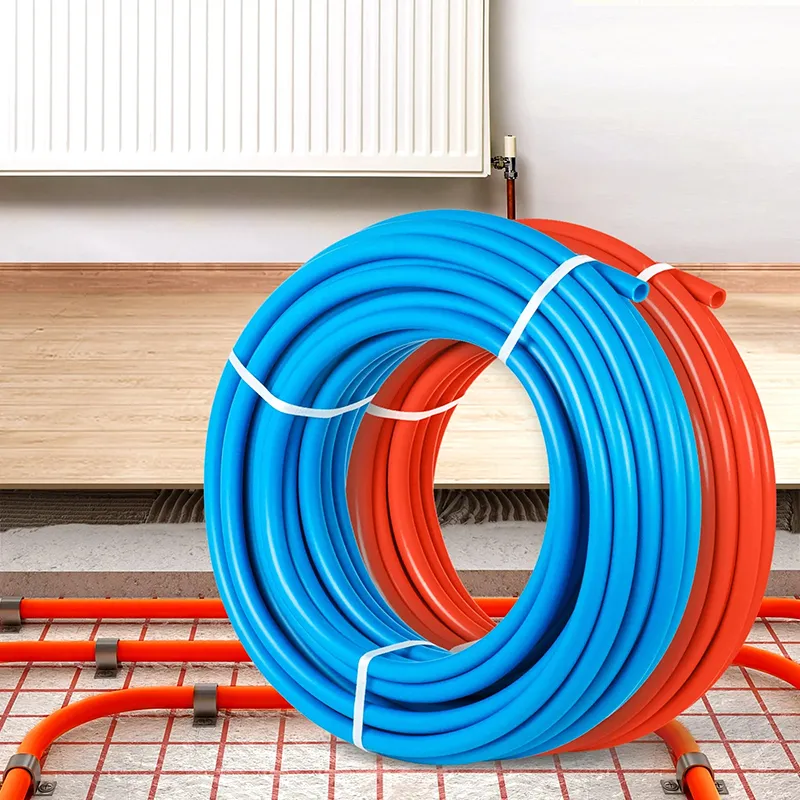

1. Because of the rigidity and linear expansion coefficient of the pe pipe, when fully considering the compressive strength problem, it is necessary to increase the total number of supporting points to ensure the rigidity of the water supply pipe network; when fully considering the linear expansion coefficient, be sure to fully consider The laying of long-distance pipelines must have the necessary amount of expansion and contraction.

2. The laying depth of the PE pipe is determined by the freezing level, the external load, the intersection of other pipes, and other factors. Under normal conditions, the laying depth can be 0.2 meters below the freezing line, and when the pipe diameter exceeds 110mm, the top buried depth of the pipe is 1.0 meters.

3. The bottom of the trench is usually the outer diameter of the pipe plus 0.4 meters, the side of the trench should be a straight line, the bottom of the trench should be a flat surface, and there should be no protrusions, gravel or other hard blocks in the trench. When digging trenches with machinery, a soil layer with a thickness of 0.2 to 0.3 meters should be left at the bottom of the trench and not excavated for the time being. It is reasonable to use manpower to clean the bottom of the trench to the elevation.

4. When the pipeline is laid, the top of the pipe shall be backfilled with 20cm of medium and coarse sand, and the bottom of the pipe shall be made of 15cm of the sand cushion.

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)