The main methods of under-pressure drilling are as follows:

1. Pipe vertical drilling

2. Fixing pipe drilling

3. Pipe-inclined hole

4. Pipe upside-down drilling

5. Tank drilling

The applicable scope of drilling under a pressure pipeline

1. Under pressure drilling of flammable and explosive medium pipeline equipment

2. Inert material under pressure pipe drilling

3. High-pressure steam under-pressure pipeline drilling

4. Operating temperature T≤300℃

5. Working pressure P≤6.4MPa

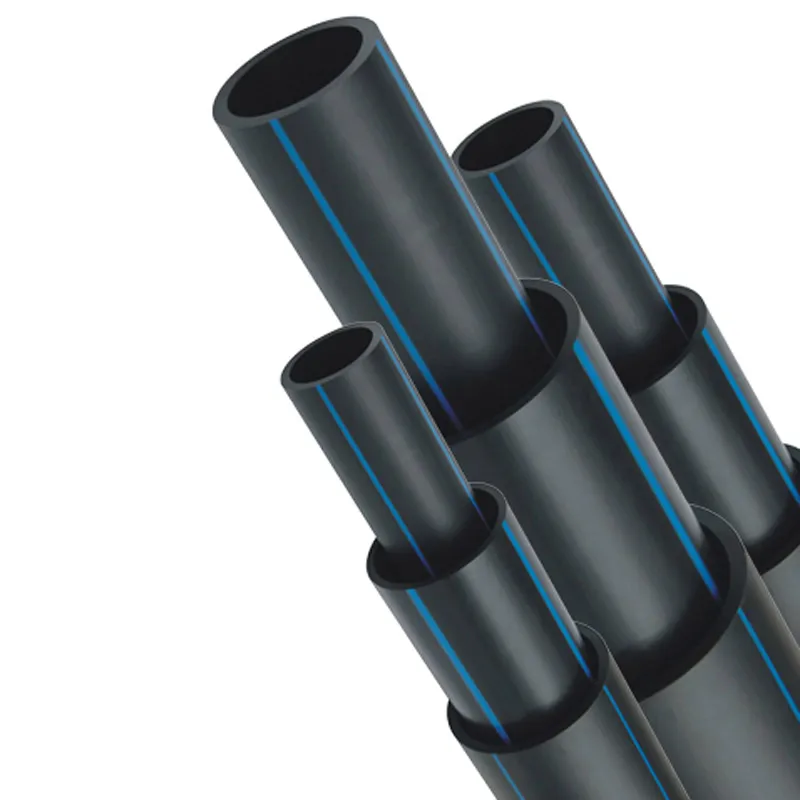

6. All kinds of welded carbon steel pipes, specifications Φ32~Φ650

7. Electric, hydraulic and manual are used in drilling

The welding between Saddle Tee fittings and Pre-drilling pipe

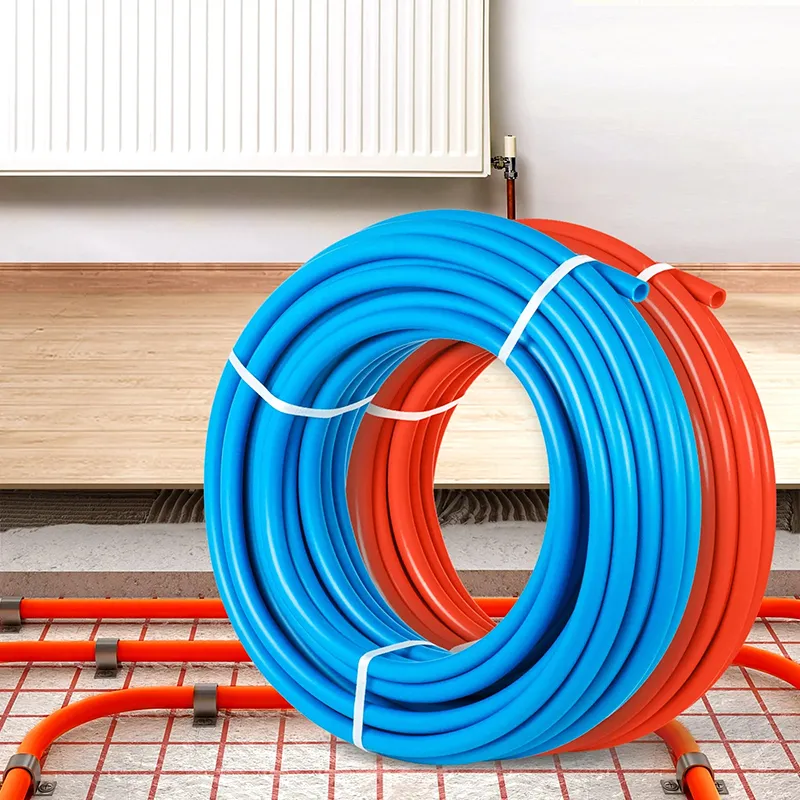

A key issue in PE pipe under pressure drilling and plugging is: how to ensure the welding quality of Saddle Tee pipe fittings and pipes to be drilled. When the construction unit repairs the PE gas pipeline, it often encounters the situation that the pipeline is perforated and the pipe fittings are not matched. Since the welding parameters (such as voltage, and heating time) of Electrofusion connection tools or Electrofusion pipe fittings produced by different manufacturers may be different, when Electrofusion is connected, the voltage and heating time of electric heating should be provided by Electrofusion connection equipment or Electrofusion pipe fittings manufacturer. parameters are performed. Before welding, the construction unit should evaluate the welding process of the pipe (piece) to determine whether it can be welded. In fact, for "special" construction such as PE under pressure drilling, it is unrealistic for the construction unit to evaluate the welding process of PE pipes and fittings from different manufacturers. To sum up, the existence of the above problems hinders the popularization and application of PE pipe under pressure drilling plugging technology.

Quality Influencing Factors of Electrofusion Connections

With the extension of the power-on time, the air-tightness of PE gas Electrofusion pipe fittings continues to increase. When the air-tightness of PE gas Electrofusion pipe fittings and pipe Electrofusion connections reaches the highest, as the power-on time continues to extend, PE gas Electrofusion pipe fittings, The air tightness of the pipe Electrofusion connection began to decrease. This is mainly because: when the energization time is too short, the pipes and fittings are not fully melted, and there is a gap between the pipes and fittings; if the energization time is too long, the melting between the pipes and the fittings is excessive, and voids are generated after cooling; only the electricity time When it is moderate, there will be no gaps and voids between pipes and pipe fittings, and the air tightness of PE gas pipe fittings and pipe Electrofusion connections will reach the highest level. As the resistance of the copper resistance wire increases, the airtightness of the PE gas pipe fittings continues to increase. When the resistance of the copper resistance wire increases to the maximum value, the airtightness of the PE gas pipe fitting and the pipe Electrofusion connection tends to be stable. This is mainly because: when the resistance of the copper resistance wire is too low, the heat generated by the resistance wire is not enough, and the plastic resin of the pipe and pipe fittings cannot be fully melted so there is a gap between the pipes and the pipe fittings. The closer the MFR of the pipe and pipe fittings, the better the compatibility, and the better the air tightness of the pipe fittings after the Electrofusion connection. The fitting size between pipes and fittings increases, and the air tightness resistance decreases after the Electrofusion connection. Only when the fitting size of pipes and fittings is between 0.05 and 0.20mm, gaps and voids will not be generated after Electrofusion, and air tightness after Electrofusion connection Sex is good.

Quality Inspection of ElectrofusionSaddle Tee Connections

For hot-melt joints, check the symmetry of the joint flanging, and the alignment of the joint, and carry out the inspection of flanging cutting. Generally, material problems such as a mismatch of melt mass flow rate, moisture, and operational problems such as improper pressure, temperature, and time parameter settings can be found. For Electrofusion connection joints, the fusion of the joints is covered in the Electrofusion pipe fittings. In the case where the molten material does not overflow a lot, the quality inspection can only be judged from the observation hole on the Electrofusion pipe fittings. Quality problems often go undetected.

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)