In the "Opinions on Strengthening Urban Infrastructure Construction" issued by the State Council, it is required to strengthen the construction and transformation of underground pipe networks such as communications. The "Opinions" clarify the current key tasks of accelerating urban infrastructure upgrading and transformation. Among them, the problem of underground pipe network is prominent, and the urban internals are frequently increasing, so it is necessary to speed up the construction of underground pipelines. Let's take a look at the types and selection points of municipal water supply and drainage pipes, as well as the trend analysis of municipal water supply and drainage pipes~

First, strengthen the construction and transformation of various underground pipe networks such as urban water supply, sewage, rainwater, gas, heat supply, and communications, and carry out pilot projects for urban underground integrated pipe corridors. The second is to strengthen the construction of urban drainage flood control and flood control facilities to solve the problem of urban water stasis. The third is to strengthen the construction of urban sewage and domestic garbage treatment facilities. The fourth is to strengthen the construction of urban road transport infrastructure. The fifth is to strengthen the construction of urban power grids. The sixth is to strengthen the construction of ecological gardens. Type of municipal water supply and drainage pipe

The types of municipal water supply and drainage pipes mainly include plastic pipes, metal pipes and reinforced concrete pipes.。1.Plastic pipe

Plastic pipe plastic pipes mainly include PVC-U pipe, PE pipe, FRPP pipe and RPM pipe. The design life of plastic pipes should not be less than 50a.

Municipal drainage plastic pipes shall be designed according to the pressureless gravity flow, and the structural calculation shall be carried out according to the flexible pipe design theory, and shall be buried below the freezing line.

1.1PVC-U tube

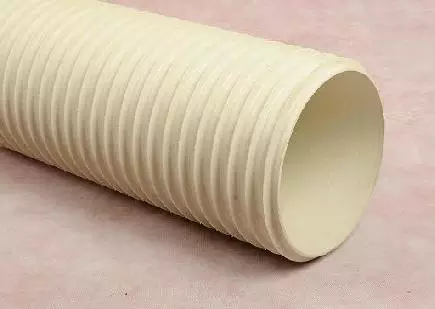

The PVC-U pipe is a hard polyvinyl chloride pipe, and the pipe wall structure has a double-wall corrugated pipe, a reinforced pipe, a flat-wall pipe and a steel-plastic composite winding pipe.

Steel-plastic composite winding pipes are usually joined by inner casing bonding. Double-wall corrugated pipes, reinforced pipes and flat-walled pipes are usually connected by sockets and sealed with rubber rings. For flat-walled pipes, when the pipe diameter is less than 200 mm, the bonding is often used.

When the PVC-U pipe is used as a drainage pipe, the concentration of hydrogen sulfide gas in the pipeline is much higher than the concentration of hydrogen sulfide gas in the concrete drainage pipe, and the sealing performance of the PVC pipe to the odor is good.

When PVC-U is used as a drain pipe, its production energy consumption only accounts for 20% of the same diameter pipe cast iron pipe, low cost, anti-aging, good heat preservation effect and long service life, so it is widely used in municipal drainage. The material of PVC-U pipe is brittle and is not resistant to external pressure. Therefore, when the pressure requirement is high, the reinforced pipe or steel-plastic composite winding pipe is used, and the compression resistance is good. Based on various advantages of PVC-U pipe, it is widely used in municipal drainage and rainwater pipelines, and it is convenient for construction and installation.

1.2PE tube

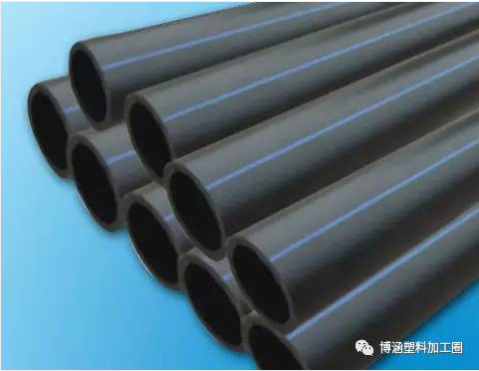

The PE pipe is a polyethylene pipe, which mainly includes a double-wall corrugated pipe, a wound structural wall pipe, a steel-plastic composite winding pipe, and a steel belt-reinforced spiral corrugated pipe.

Double-wall corrugated pipes are generally connected by socket or double sockets and sealed with rubber rings. In addition to the connection method of the double-wall corrugated pipe, the winding structure wall pipe is often welded or clamped, Huff and flanged. Steel-plastic composite winding tubes and steel belt-reinforced spiral corrugated tubes are usually joined by welding or welding.

PE pipes are divided into low-density, medium-density and high-density polyethylene pipes. In the field of municipal water supply and drainage, high-density polyethylene pipes (HDPE) are used. The pipes have strong impact resistance, heat resistance and wear resistance. It is resistant to acid and alkali corrosion and has minimal permeability. The rapid crack resistance is obviously better than PVC-U, and the heat insulation performance is good, so it is applied more in municipal water supply, drainage and rainwater. Especially in municipal water supply applications, it has the advantages of high pressure resistance, small head loss and low leakage.

1.3FRPP tube

The FRPP tube is a reinforced polypropylene tube that is usually socketed and sealed with a rubber ring. It is mainly used for municipal drainage pipes with a maximum diameter of 1500 mm.

The pipeline shall be laid on the undisturbed foundation or backfilled with compacted foundation. The net width of the groove bottom may be determined according to the diameter of the pipe, the soil condition and the construction depth of the buried depth. When excavating trenches, the substrate elevation should be strictly controlled and the base surface must not be disturbed.

1.4RPM tube

The RPM pipe is a glass fiber reinforced plastic sand pipe, and the connection method is generally a socket type connection or a double socket connection, and is sealed by a rubber ring.

The sand-filled pipe is generally used for a large-diameter drain pipe. The common one is a FRP sand pipe. The advantages are strong corrosion resistance, good physical and mechanical properties, and good heat resistance, so it is used more when transporting industrial wastewater. The disadvantage is that it is easy to become brittle and the strength is lowered at low temperatures, so it is necessary to make insulation measures in colder areas.

When the plastic pipe is sealed with elastic rubber ring, when the pipe diameter is not more than 400 mm, it can be directly inserted manually. When the pipe diameter is larger than 400 mm, special pipe tools should be used to seal the pipe joint with rubber ring. For plastic pipes larger than 800 mm, the welded joints shall be welded on both sides.

2.Metal pipe

There are three types of metal pipes in municipal water supply and drainage: water supply ductile iron pipe, drainage iron pipe and steel pipe.

The buried metal pipeline is prone to chemical corrosion due to the action of acid, alkali, salt and groundwater in the soil; it will also be electrochemically corroded under the influence of the underground potential difference. These tubes typically have a life of 25 a. Under normal circumstances, the more oxygen in the water, the more serious the corrosion; the lower the pH, the faster the corrosion; the higher the salt content, the faster the corrosion, and the corrosion is the result of the oxidation reaction and the electrolysis reaction. After the metal pipe is laid, pay attention to the construction specifications when backfilling. The project should be carefully selected according to the project design plan to select the most suitable filling machine for soil backfilling. Before the trench is backfilled, the water should be drained, and some impurities in the raw material should be removed. It is not possible to use liquefied fine sand or silt as the filler. The backfilled soil should be treated in layers. After the first layer of backfilled soil has been compacted to meet the engineering requirements, the second layer can be carried out. The fill should be carried out on both sides of the pipeline. The compactness of the fill should conform to the specifications. Claim. In the process of construction, the water raft method or backfilling with water should not be used to avoid water accumulation and cause accidents.

2.1Water supply ductile iron pipe

The water-jet ductile iron pipe has the characteristics of lightness, thin wall, pressure resistance, impact resistance, corrosion resistance and shock resistance.

The pipe interface adopts a flexible interface, and also has a certain elongation and deflection angle. It has the advantages of pig iron pipe and steel pipe material, avoiding the disadvantages of iron and steel.

The pipe interface adopts a flexible interface, and also has a certain elongation and deflection angle. It has the advantages of pig iron pipe and steel pipe material, avoiding the disadvantages of iron and steel.

2.2Drained cast iron pipe

The drained cast iron pipe has been basically replaced by PVC-U. When the drained cast iron pipe is used for a long time, the microorganisms attached to the inner wall of the water pipe are much more than the microorganisms attached to the inner wall of the PVC pipe of the same diameter, which affects the water-passing capacity, so the application is relatively small.

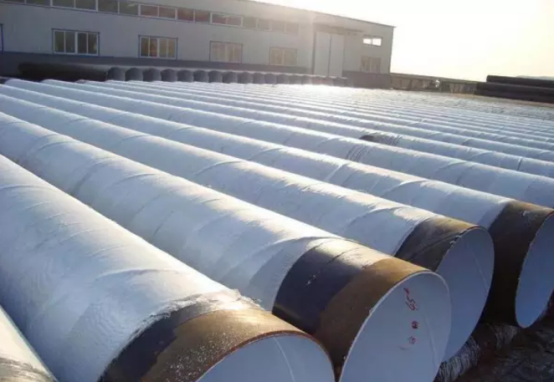

2.3Steel Pipe

Steel pipe mainly refers to welded steel pipe. The pressure resistance of steel pipe is good. When used for municipal water supply, the inner wall anti-corrosion is usually made of cement mortar, the outer wall anti-corrosion is anti-corrosion with epoxy coal tar pitch paint, and appropriate measures to prevent electrochemical corrosion are adopted. When the steel pipe is used for drainage, it is mainly used for the inlet and outlet pipes of the sewage plant structure, and it is necessary to do internal and external corrosion protection.

981.webp)

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)