Characteristics of PE gas pipe

1. Strong corrosion resistance

PE gas pipe is not corroded by humid environment, acidic and alkaline soil and various chemicals, and will not rust, corrode or scale.

Suitable for special environments such as coastal areas and wetlands, no additional anti-corrosion measures are required.

2. High flexibility and strong resistance to geological disasters

Good flexibility enables the pipeline to adapt to external pressures such as ground subsidence and earthquakes, reducing the risk of pipeline rupture.

Bendable laying reduces the use of connectors and improves system safety.

3. Reliable connection and high safety

Mainly adopts hot-melt butt and electric fusion connection methods, integrated interfaces, no leakage risk, far superior to the mechanical connection method of traditional metal pipes.

It has good crack resistance and will not suffer brittle damage even if it is impacted.

4. Lightweight and easy to install

PE pipes are much lighter than metal pipes, making them easier to transport and construct.

They can be supplied in coil form to reduce the number of joints and improve construction efficiency.

5. Excellent low-temperature resistance

It can still maintain good toughness in low-temperature environments (such as -40°C) and will not crack due to temperature changes.

6. Long service life and good economy

Under normal use conditions, the service life of PE gas pipes can reach more than 50 years.

Low maintenance cost, and the overall economy is better than metal pipes.

544684.webp)

Application areas of PE gas pipes

1. Urban gas transmission and distribution network (high-pressure, sub-high-pressure, medium- and low-pressure gas transmission)

2. Industrial and commercial gas supply systems

3. Residential gas pipelines

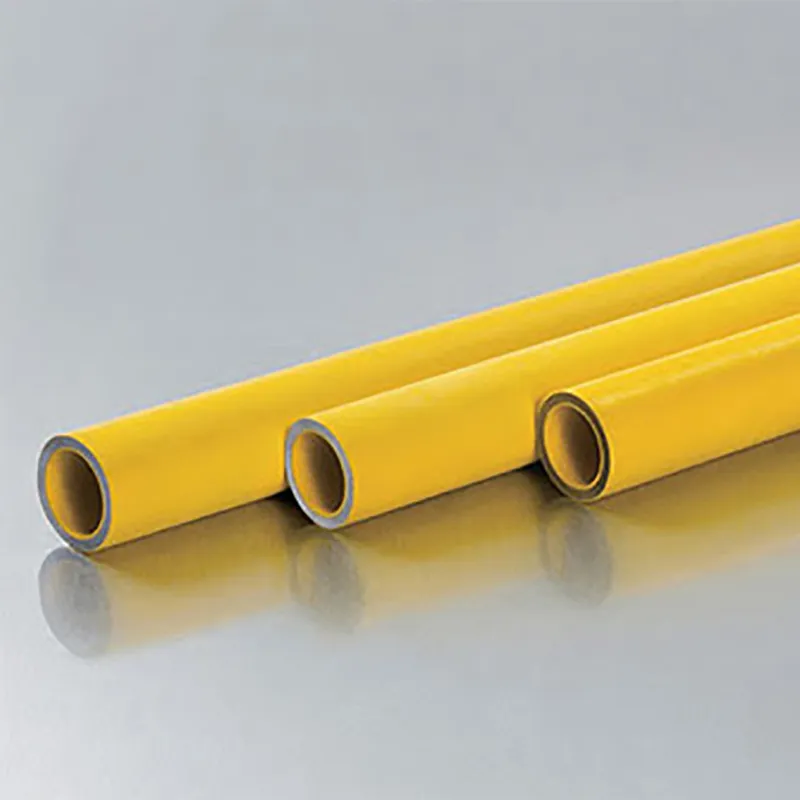

Common colors and specifications of PE gas pipes

Color: black with yellow stripes or all yellow (distinguished from other PE pipes, such as the blue stripes of water supply pipes).

Specifications: Common outer diameter 20mm-630mm, pressure level is generally within 0.4MPa (suitable for medium and low pressure gas transmission).

799885.webp)

Connection methods of PE gas pipes

Hot-melt connection: suitable for large-diameter pipes, directly welded after end surface heating, high strength.

Electrofusion connection: suitable for small-diameter pipes or connections requiring high sealing, using electric fusion pipe fittings for heating connection, easy construction.

947336.webp)

To understand gas pipelines, we must first understand how to classify them. Generally, gas pipelines are mainly divided into three aspects: pipeline purpose, laying method, and gas transmission pressure. The following will introduce them one by one:

1. Classification by purpose:

According to the purpose of gas pipelines, they can be divided into three categories: long-distance gas pipelines, urban gas pipelines, and industrial enterprise gas pipelines.

(1) Long-distance gas pipelines:

Mainly used for long-distance natural gas transmission, usually from the production or processing site to the consumption area, spanning a long geographical distance, usually with a larger pipe diameter and transmission pressure.

(2) Urban gas pipelines:

Urban gas pipelines are used to transport natural gas from gas pipelines or other gas supply sources to residential, commercial and industrial users in the city. They can be further divided into the following three types:

● Distribution pipelines: Distribution pipelines include distribution pipelines in blocks and courtyards, which refer to the distribution of gas to industrial enterprise users, public building users and residential users in the gas supply area.

● User inlet pipe: refers to the main valve that leads gas from the distribution pipeline to the user's indoor pipeline inlet.

● Indoor gas pipeline: The gas is led indoors through the main valve at the user's pipeline inlet and distributed to each gas appliance.

(3) Industrial enterprise gas pipeline: This type of pipeline serves the natural gas demand within industrial enterprises or industrial parks. It is usually a medium-pressure pipeline or a high-pressure pipeline to meet the energy demand in the industrial production process.

116429.webp)

Classification by laying method

According to the different laying methods, it can be divided into two categories: buried gas pipelines and overhead gas pipelines.

(1) Buried gas pipeline: Generally, it is often laid in cities by direct burial or trench laying. It has the advantages of high safety, no occupation of ground space, no impact on the appearance of the city, and not easily damaged by external forces.

(2) Overhead gas pipeline: When the distance between buildings is too small or the underground pipelines and structures are dense, it is difficult to bury the pipeline. Overhead laying is adopted; gas pipelines in factory areas are also often laid overhead.

997364.webp)

Classification by gas transmission pressure

According to the different gas transmission pressures, it can be divided into four categories: high pressure, sub-high pressure, medium pressure, and low pressure.

(1) High-pressure gas pipeline: The pressure range of Class A is: 2.5-4.0 (inclusive) MPa, usually a long-distance pipeline that runs through provinces, regions or connects cities.

The pressure range of Class B is: 1.6-2.5 (inclusive) MPa, usually used as the outer ring network of the transmission and distribution pipeline system in large cities.

(2) Sub-high-pressure gas pipeline: The pressure range of Class A is: 0.8-1.6 (inclusive) MPa; the pressure range of Class B is: 0.4-0.8 (inclusive) MPa;

Sub-high-pressure gas pipelines are usually used for urban gas trunk transmission, medium and large industrial users and major urban pressure regulating stations.

(3) Medium-pressure gas pipeline: The pressure range of Class A is: 0.2-0.4 (inclusive) MPa; the pressure range of Class B is: 0.01-0.2 (inclusive) MPa;

Medium-pressure gas pipelines are mainly used for urban secondary trunk transmission, regional pressure regulating stations and small and medium-sized industrial users.

(4) Low-pressure gas pipeline: pressure less than or equal to 0.01MPa

Low-pressure gas pipelines are mainly used for gas supply to end users such as residential users, commercial buildings, and community pressure regulating stations.

562071.webp)

In addition, in terms of material selection for gas pipelines, high-pressure and medium-pressure gas pipelines generally choose steel pipes, medium-pressure gas pipelines of grade A generally choose steel pipes or cast iron pipes, and medium-pressure gas pipelines of grade B and low-pressure pipelines can choose steel pipes, cast iron pipes, and polyethylene HDPE gas pipes.

| Classification of urban gas transmission and distribution pipeline transmission and distribution pressure (gauge pressure) | |

| Name | Maximum working pressure (MPa) |

| High pressure gas pipeline | |

| A | 2.5<P≤4.0 |

| B | 1.6<P≤2.5 |

| Sub-high pressure gas pipeline | |

| A | 0.8<P≤1.6 |

| B | 0.4<P≤0.8 |

| Medium pressure gas pipeline | |

| A | 0.2<P≤0.4 |

| B | 0.01<P≤0.2 |

| Low pressure gas pipeline | P≤0.01 |

981.webp)

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)