The world of valves: first impressions of ball valves and plug valves

They look similar, but there are many differences in structure, principle, performance and application. Today, let us explore the world of ball valves and plug valves, analyze the subtle differences between them, and provide precise guidance for valve selection in industrial production.

Ball valve: fast and efficient pipeline guard

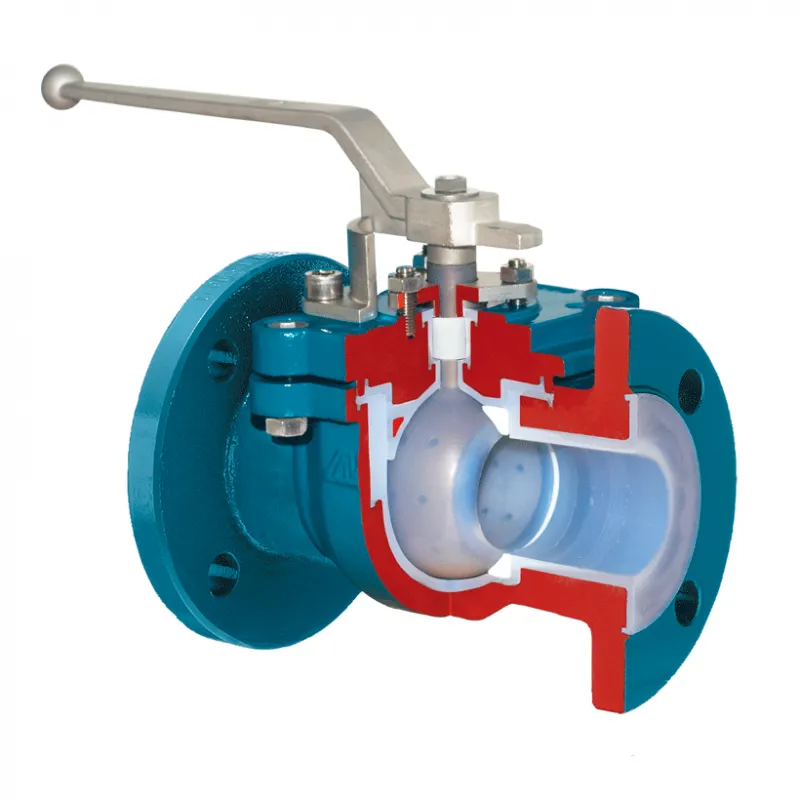

As a star product in the industrial pipeline system, the ball valve is favored for its unique structure and excellent performance. Its core component, the ball, is like a precise "control hub", and the circular through hole on the ball is the key channel for the flow of the medium.

When the valve stem drives the ball to rotate, it seems to be directing a precise dance. Just by rotating 90 degrees, the valve can be quickly opened and closed, just like a responsive guard who can quickly control the flow of fluid.

Features of ball valves

Low fluid resistance

: The passage of the ball is usually full diameter, and the resistance is small when the fluid passes through.

Quick switch

: It can be quickly switched by rotating 90 degrees.

Good sealing

: The use of materials such as PTFE can achieve a good sealing effect.

Simple maintenance

: The structure is simple and easy to disassemble and maintain.

Wide range of applications

: Applicable to a variety of media such as water, oil, and gas.

In the chemical industry, various highly corrosive acid and alkali media shuttle through the pipeline. With its corrosion-resistant valve body and sealing materials, the ball valve is not afraid of these "eroders" and stably controls the flow of the medium to ensure the safety and continuity of the production process. In the oil and gas industry, high-pressure and large-flow medium transmission places extremely high demands on the performance of the valve.

With the advantage of low fluid resistance, the ball valve allows the medium to pass smoothly, greatly reducing energy loss. At the same time, its reliable sealing performance effectively prevents the leakage of flammable and explosive media, and builds a safety line for the entire conveying system.

Plug valve: a precisely controlled flow steward

The plug valve is also an important member of the industrial pipeline system, with its own unique structure and working method. Its valve core is usually cylindrical or conical, like a delicate "control switch", which rotates flexibly in the valve body. When the valve core rotates, the internal channel and the channel of the valve body are aligned or staggered with each other, thereby accurately controlling the flow and blocking of the fluid. This rotary operation makes the plug valve show extremely high precision in flow control, especially suitable for scenes with demanding flow regulation requirements.

Plug valve features:

Structural design:

Simple and compact: It is mainly composed of valve body, plug, valve stem and other components, with few parts, simple structure, small size and light weight, which makes installation and maintenance more convenient, and also reduces manufacturing and transportation costs.

Multi-channel adaptability: It is easy to adapt to multi-channel structures and can be designed into two-way, three-way, four-way or even more channels. One valve can control multiple different flow channels, which can simplify the design of the pipeline system and reduce the amount of valves and connecting accessories.

Operation performance:

Rapid opening and closing: The plug body can usually be fully opened or fully closed by rotating 90 degrees. The operating torque is small and can be opened and closed quickly. It is suitable for occasions with frequent operations or high requirements for opening and closing speed, such as emergency cut-off or rapid switching of fluid flow direction.

Easy operation: It is suitable for occasions with frequent operations. You only need to gently rotate the valve stem to open and close the valve, which is labor-saving.

Unrestricted flow direction: It is not restricted by the flow direction of the medium during installation. No matter which direction the medium flows in, the plug valve can work normally, which provides greater flexibility for pipeline layout and installation.

Fluid control: Low resistance: The internal flow channel is relatively smooth, and the fluid encounters less resistance when passing through the valve, which is conducive to improving the flow and efficiency of the system and reducing energy consumption.

Controllable flow: The fluid flow can be precisely controlled by changing the size of the channel on the plug to meet the flow regulation requirements under different working conditions.

Sealing performance: Good sealing: The sealing surface between the plug and the valve body fits tightly, with less sealing surface, usually only including the seal of the plug and the valve body, which reduces the possibility of leakage and can effectively prevent fluid leakage. It is suitable for toxic, harmful, flammable, explosive and other media delivery pipelines with high sealing performance requirements.

Special design improves sealing: Some plug valves use special sealing designs, such as double-channel groove sealing ring structure, PTFE bushing, etc., which further improves the sealing performance and service life.

Good wear resistance: For media containing particles or impurities, the movement between the plug and the valve body during the opening and closing process of the plug valve has a wiping effect, which can reduce the accumulation and wear of particles or impurities on the sealing surface, and has good wear resistance.

Low vibration and noise: During the working process, due to the reasonable structural design, the vibration and noise generated are very small, and will not cause too much interference to the surrounding environment.

In the food industry, from the filling production line of milk and juice to the brewing process of beer, every link has strict requirements for hygiene and flow control.

The plug valve ensures the quality stability and safety of each bottle of beverage with its simple structure, easy cleaning, and precise flow regulation ability. In the pharmaceutical field, the production of drugs requires precise control of the flow of various raw materials to ensure the efficacy and safety of drugs.

The precise control characteristics of the plug valve make it an indispensable part of the pharmaceutical production line, protecting the quality of drugs. In the chemical industry, various complex chemical reactions require a precise proportion of raw materials. The plug valve can finely adjust the fluid flow according to the process requirements to help the chemical reaction proceed smoothly.

The difference between ball valves and plug valves is revealed

Structural differences: key factors that determine performance

The valve core of the ball valve is a sphere with a circular through hole. This unique spherical design makes the rotation of the sphere extremely smooth during the opening and closing process. When the through hole of the ball completely coincides with the axis of the pipeline, the valve is in a fully open state, and the medium can pass through without obstruction, like an unobstructed highway.

When the ball rotates 90 degrees and the through hole is perpendicular to the axis of the pipeline, the valve closes quickly, completely blocking the flow of the medium, like a solid barrier.

This structure is simple and clear, not only easy to operate, but also can effectively reduce the pressure loss of the fluid inside the valve, ensuring efficient transmission of the medium.

In contrast, the valve core of the plug valve is usually cylindrical or conical. When working, the valve core needs to rotate in the valve body, and the conduction and cutoff of the fluid are achieved by aligning or staggering the channel on the valve core with the channel of the valve body.

This structure makes the contact area between the valve core and the valve seat larger. When the fluid passes through, it needs to pass through a relatively narrow gap, which inevitably leads to a certain pressure loss, just like when the water flows through a narrow river, the flow rate will be hindered.

Operation characteristics: different choices of convenience and precision

In terms of operation, the ball valve can be said to be a representative of simplicity and convenience. Just rotate the valve stem and drive the ball to rotate 90 degrees, and the valve can be opened and closed quickly. The whole process is as easy as turning the steering wheel of a car. This fast operation response makes the ball valve perform well in occasions where the fluid needs to be frequently switched on and off.

For example, in the fire protection system, once a fire occurs, the valve needs to be opened quickly so that the fire water can be delivered to the fire scene in time. The fast opening characteristics of the ball valve can meet this urgent need and buy precious time for fire fighting.

In contrast, the operation of the plug valve requires a larger torque. Due to the structural characteristics of its valve core, it needs to overcome a large friction force during the rotation process, so it is relatively laborious to operate. Moreover, the valve core of the plug valve usually requires multiple turns to fully open or close the valve, which makes its operation speed relatively slow.

However, the plug valve has a unique advantage in flow regulation. By accurately controlling the rotation angle of the valve core, the size of the fluid channel can be finely adjusted, thereby achieving precise control of the flow.

This feature enables the plug valve to play an important role in some occasions where high flow control accuracy is required, such as chemical reaction devices in laboratories. In these scenarios, it is necessary to accurately control the flow of various reagents according to the specific requirements of the experiment to ensure the smooth progress of the chemical reaction and the accuracy of the experimental results.

Sealing performance: each has its own advantages and disadvantages

The sealing performance of the ball valve mainly depends on the close fit between the ball and the valve seat. When the valve is closed, the ball is tightly pressed against the valve seat under the action of the medium pressure or external force, forming a reliable sealing barrier to effectively prevent the leakage of the medium.

With the continuous advancement of sealing materials and manufacturing processes, the sealing performance of ball valves has been greatly improved, which can meet the sealing requirements under various harsh working conditions. In some gas transmission pipelines with extremely high sealing requirements, ball valves can ensure that gas will not leak under high pressure environments, ensuring the safety of gas transmission.

The plug valve achieves a good sealing effect through a multi-pass sealing design. In addition to the seal between the valve core and the valve seat, other auxiliary sealing measures are usually adopted, such as sealing rings, sealing gaskets, etc. These sealing structures cooperate with each other to effectively prevent fluid leakage.

In some high-temperature and high-pressure industrial environments, the multi-channel sealing design of the plug valve can withstand harsh working conditions and ensure that the sealing performance of the valve is stable and reliable. In the high-temperature and high-pressure reactors of the petrochemical industry, the plug valve can effectively seal the reaction medium to prevent the leakage of the medium from causing safety accidents.

Applicable occasions: precise matching according to needs

Based on the above differences, ball valves and plug valves also have different focuses in applicable occasions. With its fast opening and closing characteristics and small fluid resistance, the ball valve is particularly suitable for occasions that require rapid response, such as emergency shut-off valves in energy pipelines such as oil and natural gas.

In these pipeline systems, once a leak or other emergency occurs, the valve needs to be closed quickly to cut off the delivery of the fluid to prevent the expansion of the accident. At the same time, for some occasions where the flow regulation requirements are not high but frequent switching is required, the ball valve is also an ideal choice.

The plug valve shines in occasions with high flow control accuracy requirements due to its precise flow control ability and good sealing performance.

In the chemical production process, the ratio of various raw materials needs to be precisely controlled. The plug valve can finely adjust the flow of the fluid according to the process requirements to ensure the stability of the chemical reaction and the consistency of product quality.

In addition, in some occasions with strict requirements on sealing performance, such as food and pharmaceutical industries, plug valves can effectively prevent the leakage of the medium and ensure the hygiene of the production environment and the quality and safety of the product.

How to choose a suitable valve?

On the stage of industrial production, choosing a suitable valve is like choosing a suitable instrument for a sophisticated symphony. Every note is related to the overall harmony and stability. When we face the two choices of ball valves and plug valves, we need to consider many factors comprehensively.

First of all, the nature of the medium is the primary consideration. If the medium is highly corrosive, such as sulfuric acid, hydrochloric acid, etc., then we need to choose a corrosion-resistant valve material, such as a ball valve or plug valve made of stainless steel or special alloy.

If the medium contains solid particles, such as sewage, slurry, etc., the structural design of the valve needs to consider how to prevent particle accumulation and wear. At this time, the ball structure of the ball valve and the valve core shape of the plug valve need special attention.

Working pressure and temperature are also key factors. In high-pressure environments, the strength and sealing performance of the valve are crucial. For high-temperature conditions, the material of the valve needs to have good high-temperature resistance to prevent valve deformation or sealing failure due to excessive temperature. For example, in the steam pipeline of a thermal power plant, the working pressure and temperature are very high, so it is necessary to choose a valve that can withstand high temperature and high pressure.

Flow control requirements cannot be ignored either. If precise flow control is required, the precision adjustment capability of the plug valve may be better; while for occasions where only simple and quick cutting or conducting of the fluid is required, the ball valve is more suitable.

In addition, factors such as installation space, maintenance cost, and budget will also affect the choice of valves. In places with limited space, it may be necessary to choose a smaller valve; while valves with low maintenance costs and long service life can save the company's later operating costs.

981.webp)

(1)379.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)