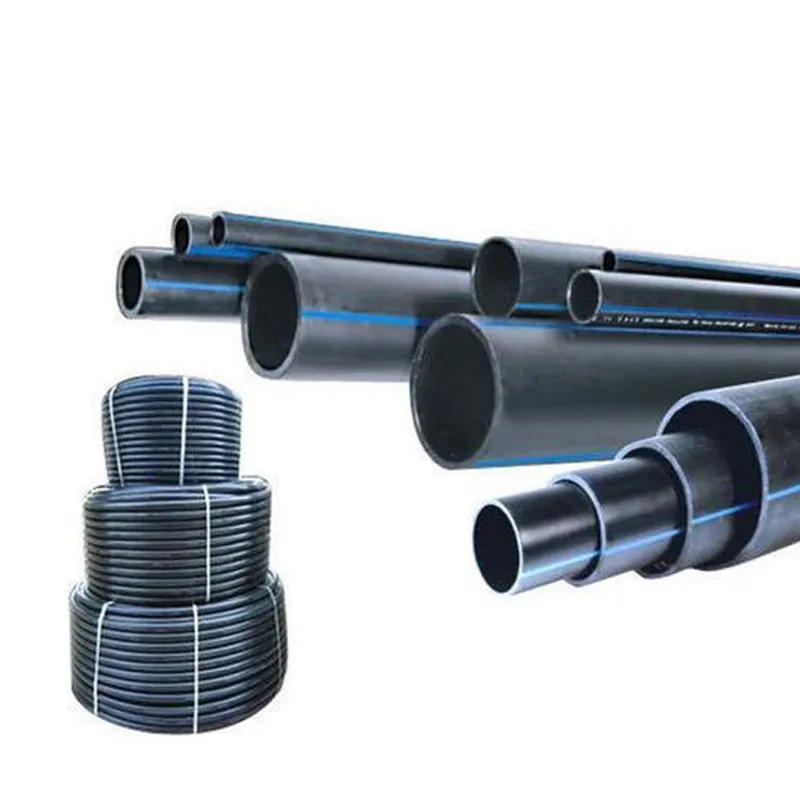

HDPE Pipe Line: An Overview

The HDPE pipe line is widely recognized for its robustness and long-lasting performance. Unlike traditional metal pipes, HDPE pipes do not corrode, rust, or deteriorate when exposed to harsh environmental conditions. This makes them ideal for transporting water, gas, and other fluids over long distances. The flexibility of HDPE pipes allows them to absorb shocks, such as those from ground movements or pressure changes, without compromising their integrity. Additionally, HDPE pipes have a low friction coefficient, which minimizes energy loss during fluid transport, making them highly efficient.

HDPE Electrofusion Fittings: Ensuring Secure Connections

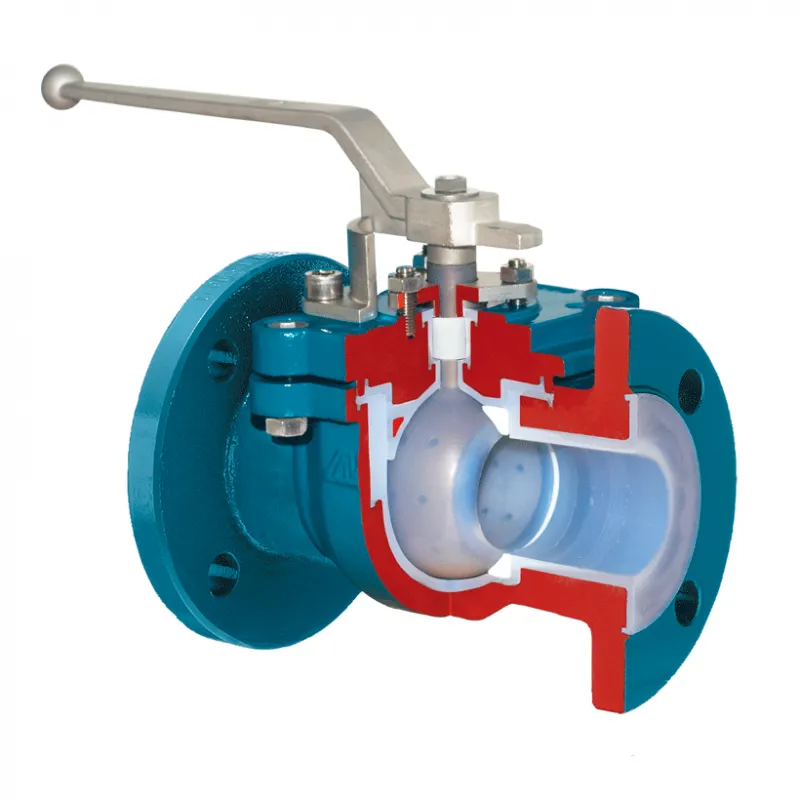

To maximize the efficiency and reliability of an HDPE pipe line, the use of HDPE electrofusion fittings is essential. These fittings are designed to create seamless, leak-proof joints between HDPE pipes, eliminating the need for traditional welding or mechanical connectors. Electrofusion fittings work by applying an electrical current to the fitting, which heats the embedded metal coils and melts the surface of the pipe and fitting. This process ensures a strong and durable bond, creating a homogenous connection that is as strong as the original pipe.

The use of HDPE electrofusion fittings is particularly advantageous in applications where system integrity is critical, such as in gas pipelines or water distribution networks. The ability to create reliable connections in challenging environments, such as underwater or in difficult-to-reach locations, further highlights the importance of these fittings in modern piping systems.

HDPE Connectors: Versatility and Adaptability

In addition to electrofusion fittings, HDPE connectors are vital components that enhance the versatility and adaptability of an HDPE pipe line. These connectors come in various forms, including couplings, elbows, tees, and reducers, allowing for the creation of complex piping networks that can navigate through different terrains and obstacles. The flexibility of HDPE connectors ensures that the piping system can be easily modified or expanded as needed without compromising its performance.

HDPE connectors are designed to maintain the integrity of the pipeline, preventing leaks and ensuring consistent flow throughout the system. They are particularly useful in irrigation systems, where they enable the distribution of water to different areas of a field efficiently. By using HDPE connectors, farmers can create customized irrigation networks that optimize water usage and promote sustainable agricultural practices.

Applications and Benefits

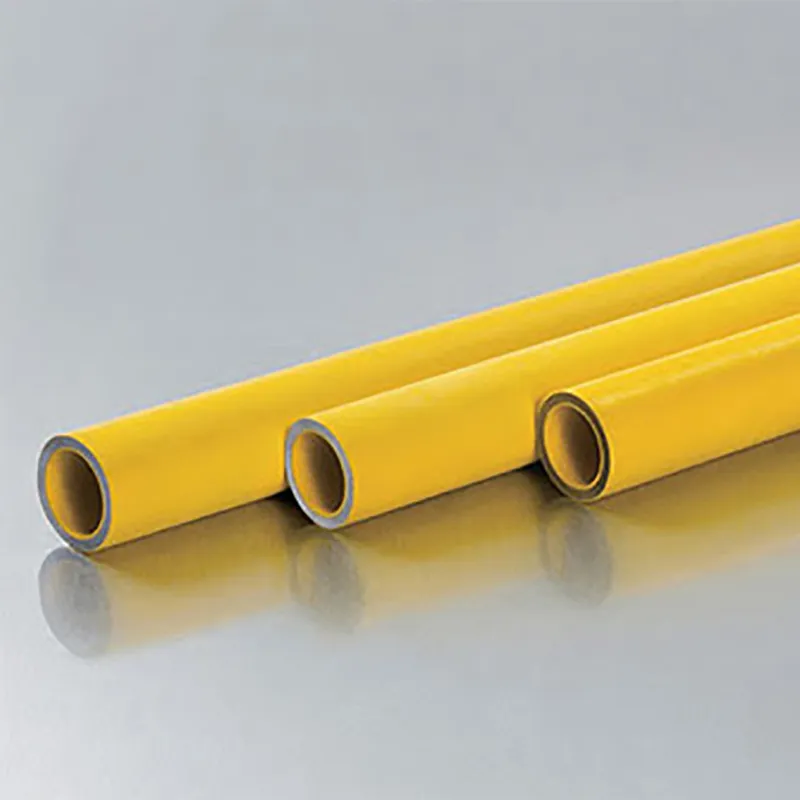

The combination of an HDPE pipe line, HDPE electrofusion fittings, and HDPE connectors offers numerous benefits across various industries. In the agricultural sector, these components are essential for creating efficient irrigation systems that reduce water waste and improve crop yields. In the oil and gas industry, the reliability and durability of HDPE piping systems ensure safe and efficient transportation of resources over long distances.

Moreover, HDPE piping systems are environmentally friendly, as they are resistant to chemicals and do not leach harmful substances into the soil or water. The long lifespan of HDPE pipes also reduces the need for frequent replacements, leading to lower maintenance costs and reduced environmental impact.

In summary, the HDPE pipe line has revolutionized modern piping systems by offering a reliable, durable, and efficient solution for fluid transportation. The integration of HDPE electrofusion fittings and HDPE connectors further enhances the performance and adaptability of these systems, making them indispensable in various industries. As the demand for sustainable and cost-effective piping solutions continues to grow, HDPE piping systems will undoubtedly play a pivotal role in meeting these challenges.

257.webp)

818.webp)

121.webp)

241.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)