Introduction

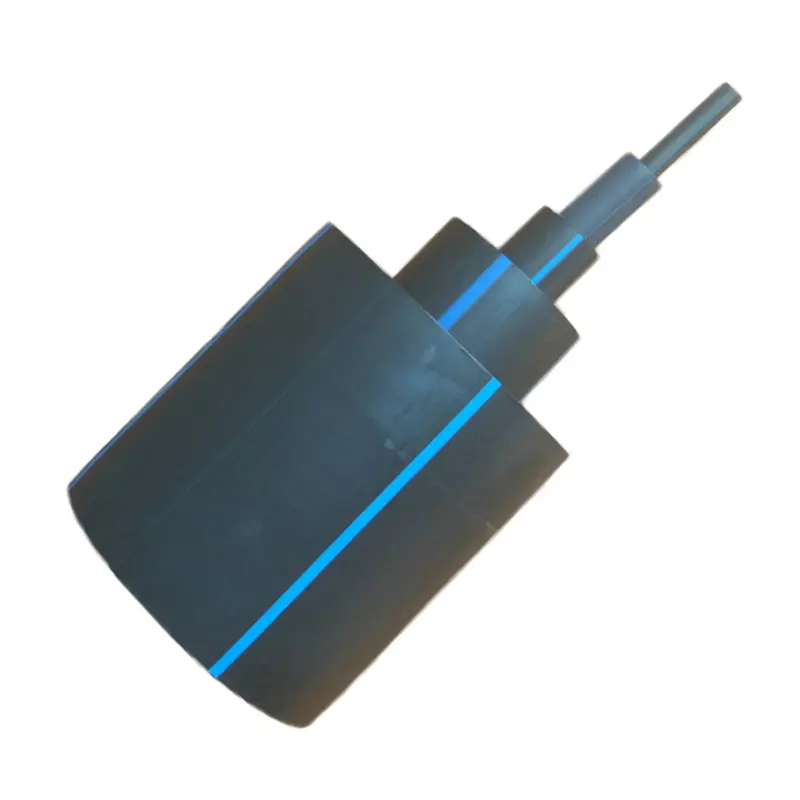

There are different types of PE black water pipe. Some of the types of HDPE black water pipes include Type 2 pipes with dimensionally integrated protective layers of PE 100 RC, Type 3 pipes with dimensions conforming to DIN 8074/ISO 4065 with an outer protective casing, and inner pipes made of PE 100 RC.

According to a press release from the Plastics Pipe Institute, “PE piping has been used for water and other fluids in Europe and America since the 1950s due to its durability, leak free joints, resistance to corrosion, and long-term cost-effectiveness.”

PE black water pipes not only has good economy, but also has a series of advantages such as stable and reliable interface, material impact resistance, crack resistance, aging resistance and corrosion resistance

The strength of the PE black water pipes hot melt or electrofusion interface is higher than that of the pipe body, and the joint is not broken due to soil movement or live Load. In addition, under the rated temperature and pressure conditions, the PE black water pipes can be safely used for more than 50 years

PE black water pipes is manufactured by extrusion in sizes ranging from ½" to 63". PE is available in rolled coils of various lengths or in straight lengths up to 40 feet. Generally small diameters are coiled and large diameters (>6" OD) are in straight lengths

206861.webp)

PE Black Water Pipes

Specification

| Specification PE80 | Specification PE100 | ||||||||||

| dn(mm) | SDR | dn(mm) | SDR | ||||||||

| SDR33 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | ||

| PN,Mpa | PN,Mpa | ||||||||||

| 0.4 | 0.6 | 0.8 | 1.0 | 1.25 | 0.6 | 0.8 | 1.0 | 1.25 | 1.6 | ||

| en(mm) | en(mm) | ||||||||||

| 0.4 | 0.6 | 0.8 | 1.0 | 1.25 | 0.6 | 0.8 | 1.0 | 1.25 | 1.6 | ||

| 25 | - | - | - | - | 2.3 | 32 | - | - | - | - | 3.0 |

| 32 | - | - | - | - | 3.0 | 40 | - | - | - | - | 3.7 |

| 40 | - | - | - | - | 3.7 | 50 | - | - | - | - | 4.6 |

| 50 | - | - | - | - | 4.6 | 63 | - | - | - | 4.7 | 5.8 |

| 63 | - | - | - | 4.7 | 5.8 | 75 | - | - | 4.5 | 5.6 | 6.8 |

| 75 | - | - | 4.5 | 5.6 | 6.8 | 90 | - | 4.3 | 5.5 | 6.7 | 8.2 |

| 90 | - | 4.3 | 5.5 | 6.7 | 8.2 | 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

| 110 | - | 5.3 | 6.6 | 8.1 | 10.0 | 125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 |

| 125 | - | 6.0 | 7.4 | 9.2 | 11.4 | 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 |

| 140 | 4.3 | 6.7 | 8.3 | 10.3 | 12.7 | 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

| 160 | 4.9 | 7.7 | 9.5 | 11.8 | 14.6 | 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

| 180 | 5.5 | 8.6 | 10.7 | 13.3 | 16.4 | 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

| 200 | 6.2 | 9.6 | 11.9 | 14.7 | 18.2 | 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

| 225 | 6.9 | 10.8 | 13.4 | 16.6 | 20.5 | 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

| 250 | 7.7 | 11.9 | 14.8 | 18.4 | 22.7 | 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

| 280 | 8.6 | 13.4 | 16.6 | 20.6 | 25.4 | 315 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 |

| 315 | 9.7 | 15.0 | 18.7 | 23.2 | 28.6 | 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

| 355 | 10.9 | 16.9 | 21.1 | 26.1 | 32.2 | 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

| 400 | 12.3 | 19.1 | 23.7 | 29.4 | 36.3 | 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

| 450 | 13.8 | 21.5 | 26.7 | 33.1 | 40.9 | 500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

| 500 | 15.3 | 23.9 | 29.7 | 36.8 | 45.4 | 560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.9 |

| 560 | 17.2 | 26.7 | 33.2 | 41.2 | 50.9 | 630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 |

| 630 | 19.3 | 30.0 | 37.4 | 46.3 | 57.2 | 710 | 27.2 | 33.9 | 42.1 | 52.2 | - |

| 710 | 21.8 | 33.9 | 42.1 | 52.2 | - | 800 | 30.6 | 38.1 | 47.4 | 58.8 | - |

| 800 | 24.5 | 38.1 | 47.4 | 58.8 | - | 900 | 34.4 | 42.9 | 53.3 | - | - |

| 900 | 27.6 | 42.9 | 53.3 | - | - | 1000 | 38.2 | 47.7 | 59.3 | - | - |

| 1000 | 30.6 | 47.7 | 59.3 | - | - | 1200 | 45.9 | 57.2 | 67.9 | - | - |

| 1200 | 36.7 | 57.2 | 67.9 | - | - | 1400 | 53.5 | 66.7 | 82.4 | - | - |

| 1400 | 42.9 | 66.7 | 82.4 | - | - | 1600 | 61.2 | 76.2 | 94.1 | - | - |

| 1600 | 49.0 | 76.2 | 94.1 | - | - | ||||||

Why are PE black water pipes widely used?

✔PE black water pipes offer several benefits over other drilling rigs such as:

✔Reduction of installation costs due to its flexible shape

✔It is easy to use on slopes

✔Resistance to freezing

✔Resistance to corrosion

✔Resistance to fatigue

✔Lightweight and easy to transport

✔Easy to install

✔Resistance to heat and cold

✔Safety of potable water and long-term reliability

PE black water pipes are used for a variety of purposes.

Here are some general steps on how to use PE water pipes:

✔Cut the pipe to the desired length.

✔Clean the pipe and fittings.

✔Insert the pipe into the fitting.

✔Tighten the fitting.

Applications

PE80 water pipes, also known as MDPE (Medium-Density Polyethylene) pipes, have several applications due to their unique properties. Some of the common applications of PE80 water pipes include:

1. Water supply systems for delivery of potable water to homes and commercial establishments

2. Gas distribution systems for transporting natural gas, propane, and other liquefied gases

3. Agricultural irrigation systems for transporting water to irrigation systems

4. Use in swimming pools or aquaculture systems

5. Effluent disposal systems

6. Industrial fluid transfer systems predominantly in chemical, mining and construction industries.

If you have any inquiry about HDPE Pipe and Fittings, Contact Us Now! Get A Free Quote Quickly!

Factory Video

425.webp)

369.webp)

647.webp)

460.webp)

489.webp)

476.webp)

420.webp)

720.webp)

294.webp)

146.webp)