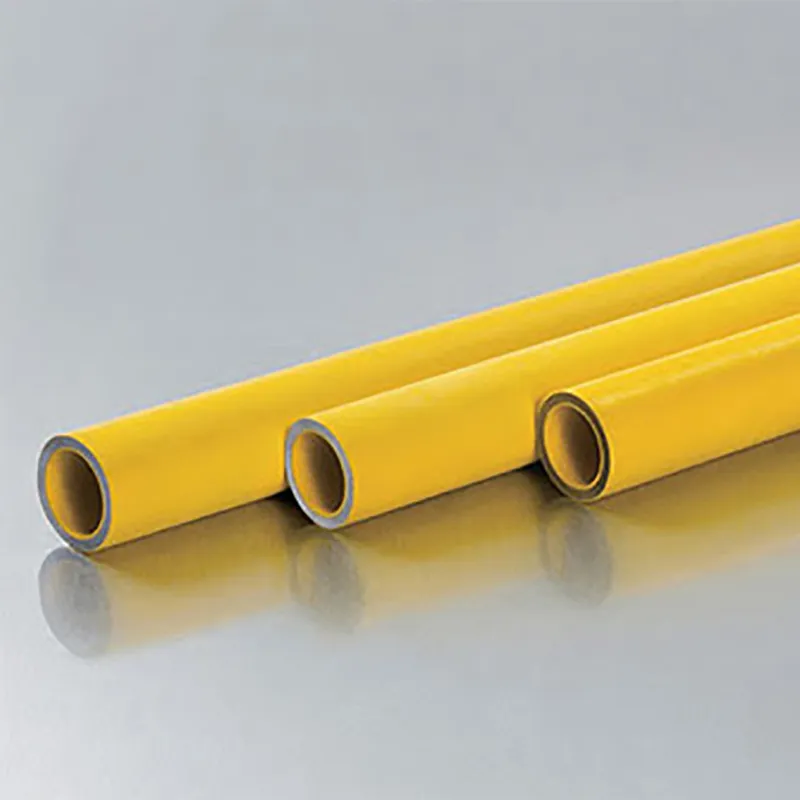

What is HDPE Irrigation Pipe?

Definition and Composition

HDPE irrigation pipes are made from high-density polyethylene, a thermoplastic polymer known for its high strength-to-density ratio. These pipes are specifically designed for irrigation systems, providing a reliable and efficient method for delivering water to crops and fields.

Key Features

1. Durability: HDPE pipes are highly resistant to impact, corrosion, and environmental stress, making them suitable for long-term use in various conditions.

2. Flexibility: The inherent flexibility of HDPE allows these pipes to withstand ground movements and temperature fluctuations without cracking or breaking.

3. Chemical Resistance: HDPE material is resistant to a wide range of chemicals, ensuring that the pipes remain unaffected by fertilizers and pesticides used in agricultural practices.

What is Water Poly Pipe?

Definition and Composition

Water poly pipes, commonly referred to as PE pipes, are used for the distribution of potable water, industrial water, and wastewater. Like HDPE pipes, water poly pipes are made from high-density polyethylene, which offers excellent performance and longevity.

Key Features

1. Safe for Drinking Water: PE pipes are certified for carrying potable water, ensuring that there is no contamination from the pipe material.

2. Longevity: These pipes have a lifespan of up to 100 years, reducing the need for frequent replacements.

3. Low Maintenance: The smooth interior surface of PE pipes (fitting) prevents sediment buildup, reducing maintenance requirements and ensuring consistent water flow.

Advantages of HDPE Irrigation Pipes and Water Poly Pipes

1. Cost-Effectiveness

Both HDPE irrigation pipes and water poly pipes are cost-effective solutions. Their long lifespan and minimal maintenance requirements translate to significant cost savings over time. Additionally, the ease of installation reduces labor costs.

2. Environmental Benefits

HDPE and PE pipes are environmentally friendly. They are recyclable and have a low carbon footprint compared to traditional piping materials. Their durability also means fewer replacements and less waste over time.

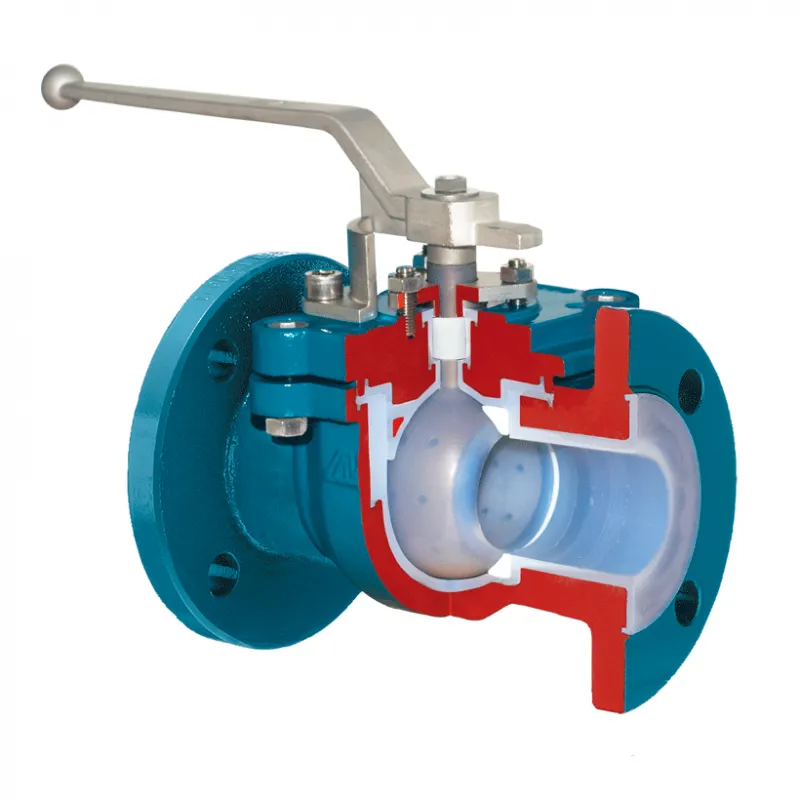

3. Leak-Free Joints

The fusion welding technique used to join HDPE and PE pipes creates a leak-free system. This is particularly important in irrigation and water supply systems where water conservation is a priority.

4. Versatility

HDPE and PE pipes can be used in a variety of applications beyond irrigation and potable water supply, including gas distribution, sewage systems, and industrial processes. Their versatility makes them a preferred choice in many sectors.

Installation of HDPE Irrigation Pipes and Water Poly Pipes (Fitting)

Preparation

1. Site Assessment: Before installation, a thorough site assessment is essential. This includes soil testing, measuring the area, and planning the pipe layout.

2. Pipe Selection: Choose the appropriate pipe diameter and pressure rating based on the specific requirements of the project.

Installation Steps

1. Trenching: Dig trenches according to the planned layout. Ensure the trenches are free from sharp objects that could damage the pipes.

2. Laying the Pipes: Place the pipes in the trenches, ensuring they are straight and properly aligned. Use pipe supports if necessary.

3. Joining the Pipes: HDPE and PE pipes are typically joined using fusion welding, which involves heating the pipe ends and fusing them together to create a strong, leak-proof joint.

4. Backfilling: Once the pipes are laid and joined, carefully backfill the trenches, ensuring there are no sharp objects that could damage the pipes.

Testing

After installation, conduct pressure tests to ensure the system is leak-free and functioning correctly. This step is crucial to identify any potential issues before the system is put into operation.

Maintenance of HDPE Irrigation Pipes and Water Poly Pipes

Regular Inspections

1. Visual Inspections: Regularly inspect the pipes for any visible signs of damage or wear.

2. Leak Detection: Use leak detection equipment to identify any hidden leaks in the system.

Cleaning

1. Flushing: Periodically flush the system to remove any sediment or debris that may have accumulated.

2. Chemical Cleaning: In case of severe buildup, use approved chemical cleaners to ensure the pipes remain clean and functional.

Repairs

1. Minor Repairs: For small leaks or cracks, use appropriate repair kits designed for HDPE and PE pipes.

2. Major Repairs: In case of significant damage, replace the affected section of the pipe. Ensure proper fusion welding to maintain a leak-free system.

Applications of HDPE Irrigation Pipes and Water Poly Pipes

Agricultural Irrigation

HDPE irrigation pipes are extensively used in agricultural irrigation systems. They provide a reliable and efficient means of water delivery, ensuring that crops receive adequate water for optimal growth. The flexibility and durability of HDPE pipes make them ideal for use in fields with varying terrain.

Potable Water Supply

Water poly pipes are the preferred choice for potable water supply systems. Their ability to carry drinking water without contamination ensures safe and clean water for households and communities.

Industrial Applications

In industrial settings, HDPE and PE pipes are used for the transport of various liquids, including chemicals and wastewater. Their chemical resistance and durability make them suitable for harsh industrial environments.

Sewage and Drainage Systems

HDPE and PE pipes are also used in sewage and drainage systems. Their resistance to corrosion and chemical attack ensures the longevity and reliability of these critical infrastructure systems.

HDPE irrigation pipes and water poly pipes are indispensable components in modern water management systems. Their durability, flexibility, and cost-effectiveness make them the preferred choice for a wide range of applications. By understanding their characteristics, installation procedures, and maintenance requirements, users can ensure the efficient and long-term performance of these piping systems.

Investing in high-quality HDPE and PE pipes not only improves water distribution efficiency but also contributes to environmental sustainability. As technology advances and new innovations emerge, the use of HDPE and PE pipes is expected to grow, further enhancing their role in sustainable water management.

For more information on HDPE irrigation pipes and water poly pipes, and to explore our wide range of products, visit our website or contact our experts today. We are committed to providing you with the best solutions for all your water management needs.

257.webp)

818.webp)

121.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)