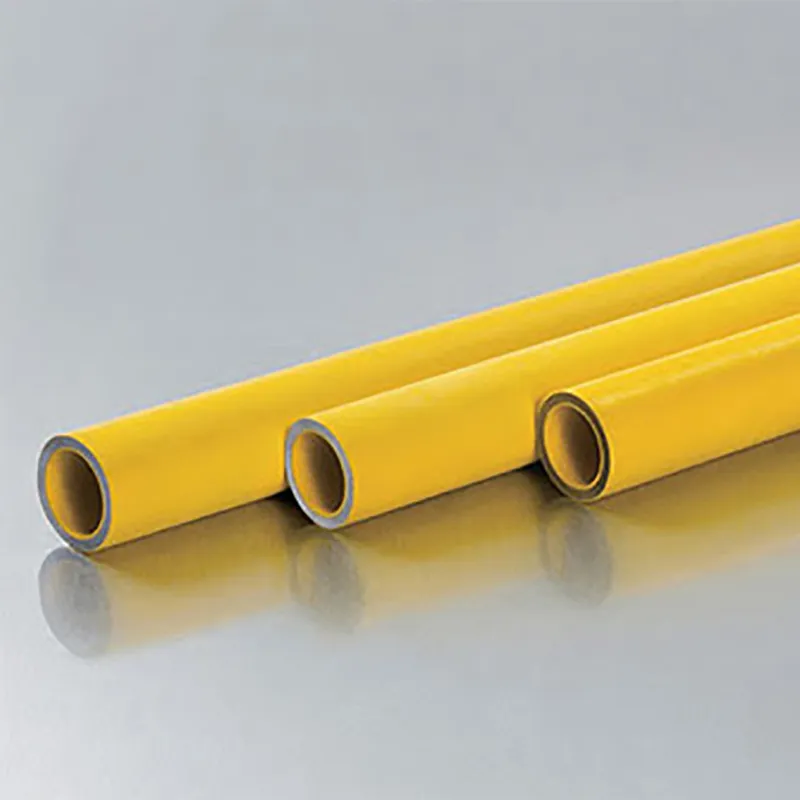

HDPE electrofusion fittings are widely used in Vietnam as a durable solution for joining polyethylene pipes. Electrofusion fittings are particularly useful in joining HDPE pipes due to their resistance to chemicals, abrasions, and overall toughness. In Vietnam, HDPE electrofusion fittings are utilized in various applications, including water distribution, gas distribution, and industrial piping systems. One benefit of using HDPE electrofusion fittings in Vietnam is their simple installation process. These fittings require minimal training and can be installed quickly, reducing installation costs and time. The ability to fuse pipes and fittings together using electrical resistance ensures a strong, leak-proof joint that is resistant to wear and tear. The fittings are also flexible, allowing them to fit pipes of varying diameters, making them a versatile option in a range of applications. In recent years, Vietnam has experienced rapid economic growth, with a subsequent increase in infrastructure development. As a result, the demand for HDPE electrofusion fittings in Vietnam has seen steady growth. The increasing use of these fittings in the country is further driven by their long life-span and low maintenance requirements. The fittings can withstand harsh environmental conditions, making them an excellent option for long-term investment in the country's infrastructure. To meet the high demand for HDPE electrofusion fittings in Vietnam, various manufacturers have established plants to supply the fittings. Some of these manufacturers may also customize HDPE electrofusion fittings to meet customers' specific needs. In Vietnam, there is a wide choice of HDPE electrofusion fittings available from both domestic and international sources. Nonetheless, it is essential for end-users to choose electrofusion fittings that meet the required quality and safety standards. It is necessary to choose quality electrofusion fittings from reliable and reputable sources to ensure long-term service and safe piping systems. In conclusion, HDPE electrofusion fittings have become a preferred solution for joining HDPE pipes in Vietnam. The fittings offer many advantages, including simple installation, strong joints, and durability, making them a great choice for a range of applications, from industrial piping systems to water distribution. Choosing the right manufacturer and product is crucial to ensure the fittings meet the necessary quality and safety standards.

There are many different types of HDPE electrofusion fittings available, each designed for a specific purpose or application. Here are a few examples of the most common types:

1. Couplings: Couplings are used to connect two HDPE pipes together in a straight line. They come in various sizes to accommodate different pipe diameters.

2. Elbows: Elbows are used to change the direction of an HDPE pipe. They are available in 90-degree and 45-degree angles.

3. Tees: Tees have three openings, making them perfect for branching an HDPE pipeline in three directions.

4. Reducers: Reducers are used to transition between two different pipe sizes. They can be used to either increase or decrease the diameter of the pipeline.

5. End Caps: End caps are used to seal the end of an HDPE pipeline. They prevent the entry of foreign materials and ensure that the pipeline is leak-proof.

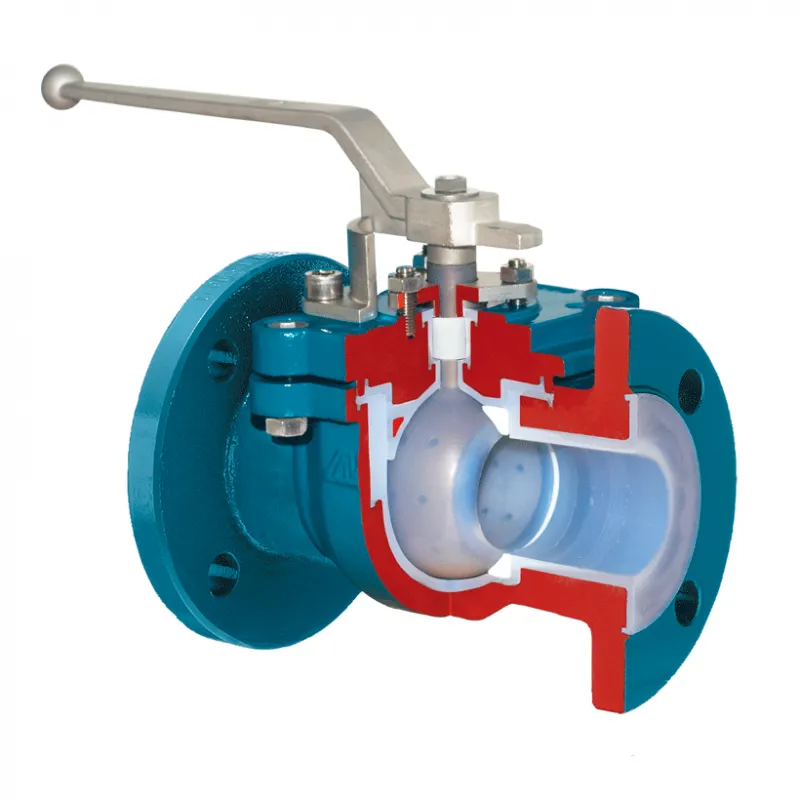

6. Saddle Fittings: Saddle fittings are designed to be attached to an existing pipeline to create a branch connection. They are commonly used in irrigation systems and for connecting service lines to main pipelines. There are also specialized HDPE electrofusion fittings available for specific applications, such as geothermal systems, gas distribution, and fuel handling. The specific type of fitting needed for a particular application will depend on the requirements of the project.

How to choose hdpe electrofusion fittings in Vietnam?

Choosing the right HDPE electrofusion fittings in Vietnam is crucial to ensure a safe and reliable pipeline system. Here are some key factors to consider when selecting HDPE electrofusion fittings in Vietnam:

1. Material Quality: The quality of the electrofusion fittings must be considered to ensure they can withstand harsh environmental conditions and provide long-term service. When purchasing HDPE electrofusion fittings in Vietnam, it is essential to choose fittings made from high-quality materials that meet the standards required for the application and comply with Vietnam's regulations and standards.

2. Size and Diameter: Like any fitting, it is important to choose HDPE electrofusion fittings that match the size and diameter of the pipe. HDPE electrofusion fittings should have a similar dimension to the pipe that they will be installed on, to ensure they fit securely and function efficiently.

3. Application and Pressure Rating: The specific application of the electrofusion fittings needs to be considered before making a purchase. Different applications require different types of fittings, such as tees, couplings, elbows, and reducers. The chosen fitting should match the system's maximum operating pressure and be suitable for the specific application and environmental conditions.

4. Manufacturer and Supplier: Purchasing HDPE electrofusion fittings from reputable manufacturers and suppliers can ensure that the fittings meet the required standards and are of high quality. It is crucial to choose a reputable and experienced supplier who can provide excellent customer advice, quality assurance, technical support, and reliable logistics.

5. Price and Cost-effectiveness: While the cost of the product is essential, it should not be the only deciding factor when choosing an HDPE electrofusion fitting. It is important to evaluate the total cost of the installation, including installation time and required support to select the most cost-effective option.

6. Warranty and After-sales Services: Choosing HDPE electrofusion fittings that come with a warranty and after-sales services offers peace of mind and protects the investment in the event of any issues with the fitting.

Considering these factors when selecting HDPE electrofusion fittings in Vietnam can help ensure a safe, reliable, and cost-effective pipeline system that meets the specific needs and requirements of the project.

477.webp)

257.webp)

818.webp)

121.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)