Applications of HDPE Pipe Lines

Water Supply: Municipal and rural water delivery systems.

Sewage and Drainage: Underground systems for transporting wastewater.

Gas Distribution: Low-pressure natural gas pipelines.

Agricultural Irrigation: Water distribution systems for farming.

Industrial Use: Transporting chemicals, slurries, or industrial waste.

Mining: Used for slurry pipelines and tailings management.

Telecommunication: Protecting cables in conduit systems.

HDPE Pipe is In Demand

When you think of pipes, what may first come to mind are more traditional materials like copper, ductile iron, concrete, or clay. But the future of pipe is being driven by HDPE – and for good reasons. The durability, sustainability, flexibility, chemical and corrosion resistance, light weight, affordability, and robust properties of HDPE plastic has made it a prime choice for a wide array of HDPE pipe applications in:

Oil and gas

Water and wastewater infrastructure

Residential construction and agricultural sectors

The growth of oil and gas exploration activities has directly driven the demand for pipeline infrastructure, especially in the transportation, storage and distribution processes.

The following is the impact of this growth on pipeline demand, as well as the specific types of pipelines that have increased demand

I. Overall impact on pipeline demand

1. Increased demand

As oil and gas exploration and production activities expand, larger pipeline networks are needed to connect oil fields, gas wells, refineries and consumer markets.

2. Increased technical requirements

Exploration activities often involve extreme environments (such as deep sea, high pressure areas or extremely cold areas), which puts higher requirements on the pressure resistance, corrosion resistance and long-term stability of pipelines.

3. Regional expansion

With the discovery and development of new oil and gas fields around the world (such as Africa, Southeast Asia and the Arctic), the demand for pipelines in these regions has increased significantly.

4. Increased environmental requirements

Modern pipeline systems need to meet more stringent environmental standards to reduce the risk of leakage and greenhouse gas emissions.

II. Types of pipelines with increased demand

1. Oil pipelines

Function

Used to transport crude oil from oil fields to refineries or ports.

Reasons for demand growth: Increased crude oil production, especially in new exploration areas such as deep sea and shale oil fields.

Features

Must have high pressure resistance and corrosion resistance.

Requires special inner coating to reduce friction during transportation.

2. Gas pipelines

Function: Responsible for the transportation of natural gas from gas fields to industrial or household users.

Reasons for demand growth

Increasing demand for natural gas as a clean energy source

The development of the LNG (liquefied natural gas) industry promotes the construction of natural gas pipelines.

Features

Usually high-pressure pipelines, the material needs to have extremely strong pressure resistance.

Steel pipelines are often used in combination with plastic pipes such as HDPE as a secondary distribution network.

3. Gathering pipelines

Function: Short-distance transportation from wellhead to central processing station or storage tank.

Reasons for demand growth: Increased oil field exploration activities have led to the construction of more wellhead facilities.

Features

The pipeline is relatively short, but it needs to be resistant to sulfide corrosion (H2S gas is common in oil and gas fields).

Use seamless steel pipes or composite pipes.

4. Subsea pipelines

Function: Transport resources from offshore oil and gas platforms to onshore processing facilities.

Reasons for demand growth: Increased deep-sea oil and gas exploration activities.

Features

Can withstand high pressure and corrosion in deep-sea environments.

Use special coatings or composite materials (such as anti-corrosion coatings).

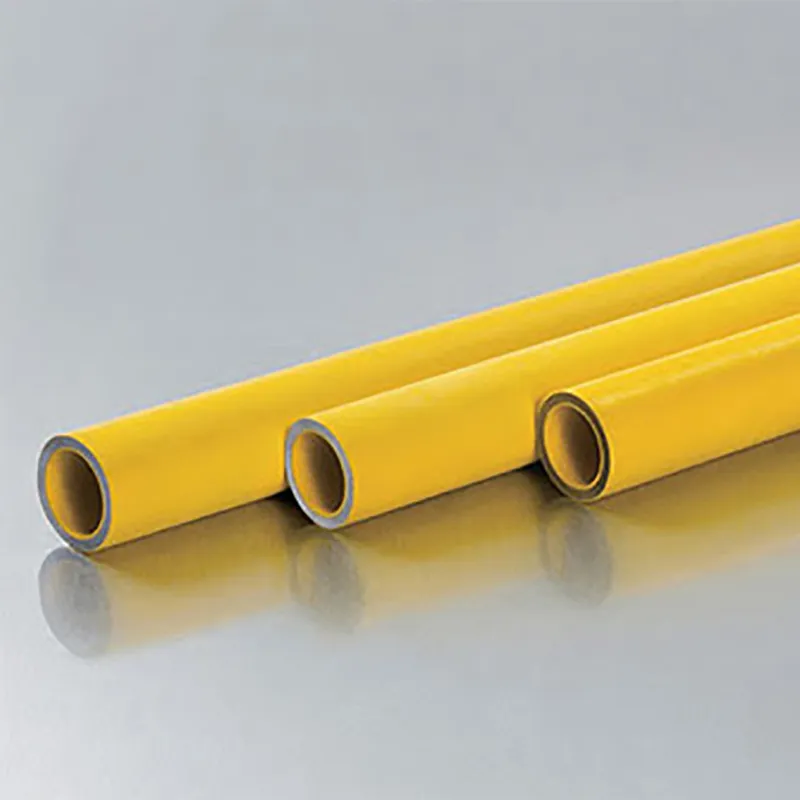

5. Polyethylene (PE) and HDPE pipes

Function:

Used in secondary transmission and distribution networks (natural gas or water supply).

Reasons for demand growth

HDPE pipes are easy to lay and suitable for medium and short-distance distribution systems.

The expansion of the natural gas user network promotes increased demand.

Features

Good flexibility, suitable for trenchless construction.

Corrosion resistance and long life.

6. Composite pipes (GRE, GRP)

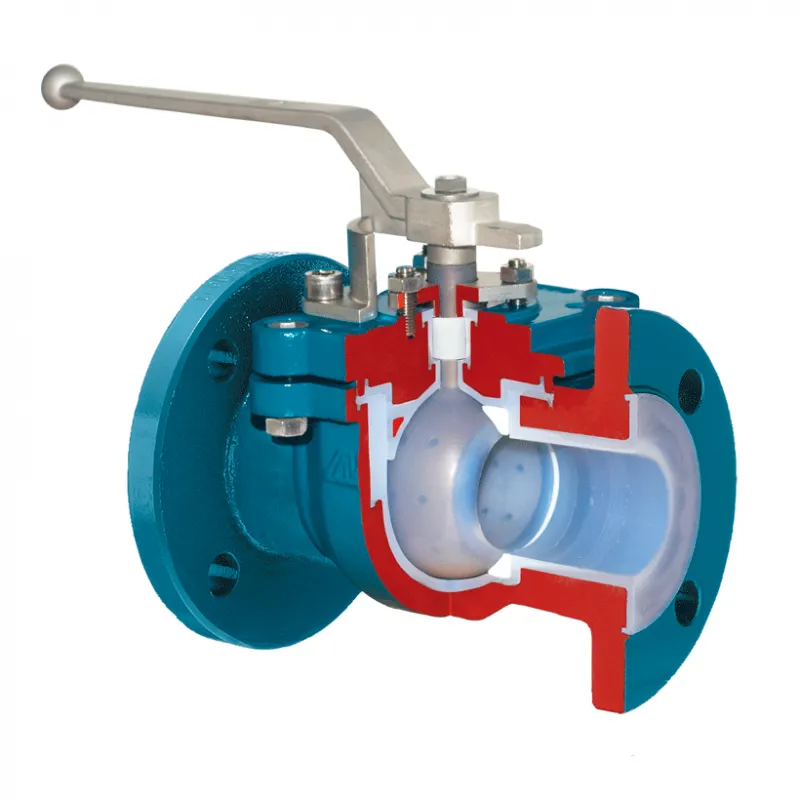

Function: Replace metal pipes for corrosion resistance and high-pressure transportation.

Reasons for demand growth: Increased application scenarios in high hydrogen sulfide or other corrosive environments.

Features: Light weight and excellent chemical resistance.

III. Factors driving the growth in pipeline demand

1. Energy transformation: The demand for natural gas as a transitional energy source has increased, increasing the demand for the construction of gas pipelines.

2. Oil and gas resource development: Shale gas and deep-sea oil field development have spawned new oil and gas pipeline networks.

3. Regional cooperation: Transnational oil and gas pipelines (such as the "Belt and Road" related projects) have promoted the demand for international energy resource transportation.

4. Technological development: New materials (such as HDPE and composite materials) make pipelines more efficient and environmentally friendly.

The increase in oil and gas exploration activities has significantly driven the growth in demand for oil, gas, submarine hdpe pipe lines and composite pipelines. In the future, with stricter environmental regulations and technological advances, corrosion-resistant, high-pressure, and energy-saving pipelines will become the mainstream demand of the market.

257.webp)

818.webp)

121.webp)

294.webp)

476.webp)

420.webp)

146.webp)

460.webp)

287.webp)

274.webp)

688.webp)